|

Introduction My name is Carbolic Smokeball and I've worked in Canada's oil sands for the last three years. If you live in North America, you've likely heard of the controversial oil sands in the Athabasca region of northern Alberta. If you're Canadian, you know it because of the provincial and federal governments' mandates to expand oil sands development seemingly at any cost. If you're in the United States, you probably know about it because of Keystone XL, the proposed pipeline to bring Alberta bitumen from Alberta to refineries in Illinois and Texas. What Do I Do? I work as a process operator for one of the big players up here in the oil sands, although there are many names for what I do. Plant operator, power engineer, stationary engineer, field operator are all possible job titles. We're the heartbeat of not just the oil industry, but all industry. You'll find us in pulp and paper, power plants, heating plants (such as in a mall or hospital), breweries, smelters, and even large laundromats. We work around the clock to make sure that the plants run safely and efficiently, and, in commodity based industries, to maximize production. Up here we work almost exclusively 12-hour shifts, but the amount of days worked depends on which company you're with. Some do 3 days/3 nights/6 off, some do 7/7, alternating days and nights each set, up to 14/14. Occasionally you'll see weird ones like 5/4/4/5 and the like but they're few and far between. What Are The Oil Sands? Oil sands are sandy deposits saturated with a dense and highly viscous petroleum known as bitumen. Canada is home to the largest known reserves of oil sand in the world, which also means it has the third largest proven reserves oil in the world that is economically viable to recover. The vast majority of oil sands development in Canada is in the province of Alberta, and most of it is focused around the boomtown of Fort McMurray, (otherwise known to the rest of the country as Fort McMoney), which is where I live.  How Is It Extracted For decades, the majority of oil sands production was done by strip mining. Large hydraulic shovels dig up oil sand and place it in heavy hauler, which will then bring it for processing. The sand is mixed with hot water and a hydrocarbon based diluent (usually naphtha) in order to separate the oil from the sand. The sand is discarded in a tailings pond, but the oil is still too heavy for refining to an end product.  From extraction, it will be sent to an Upgrader, which is kind of like a early stage refinery. The upgrader will "upgrade" the oil into a lighter, higher-quality synthetic crude oil where it can be sent for further refining into an end product, such as gasolene, kerosene, or oil for consumer products. The whole process is much more energy intensive than traditional crude oil extraction, which contributes to the "dirty oil" monicker. However, in the last 20 years a new method of extraction has developed. Steam Assisted Gravity Drainage, or SAGD, is a relatively new technology. The concept itself has been around since the 1970s, but only in the last 20 has development really expanded. SAGD involves inserting a pair of horizontal wells into the oil sands. Steam is injected into the top pipe of the well, which "melts" the oil from the sand. The oil pools in the bottom of the well, where it is collected by the bottom pipe and is pumped back to the surface for processing. SAGD has proven immensely successful in the oil sands, as plants are significantly cheaper to construct and operate, require no tailings ponds, and disturb virtually no land in comparison to strip mining. As a result, several small satellite sites have popped up all over the province. Some are new ventures, others are owned by the big companies. It is estimated that only around 20% of oil sands can be accessed from surface mining. Strip mining can only access the sand around 75 meters deep, where as SAGD can reach deposits 500 meters down or lower.  Why I Made This Topic I think a lot of people don't really know much about what goes on up here, and there's a lot of misconceptions about the industry and Fort McMurray in general. I haven't been here all that long but it's been long enough to know what is right and wrong in terms of what people think life is like up here.

|

|

|

|

|

| # ? Apr 25, 2024 08:50 |

|

How do you dig those horizontal tunnels through the sand? Is the oily sand so sticky it doesn't need much support? I can see how you could put in a perforated pipe for the steam delivery, but how does the recovery pipe collect the oil without collapsing? Doesn't the process disturb the sand and result in the tunnels trying to collapse once the oil has been leached out? What is it about the geology of this area that caused the oil deposits to form like this? How does their presence effect the life on the surface?

|

|

|

|

A special kind of tool is used to bore the holes in the ground. It looks like three interlocked round heads with several spikes that gradually tear away the earth around them as they spin. A water-clay mixture is pumped into the well as it is being drilled to both cool the drill and collect the dirt and rock torn by the drilling process. The drills must be strong enough to dig through a layer of shale caprock. Once through the caprock the drills gradually curve into the deposit until they are horizontal. Horizontal drilling (the length of the well) may go on for several kilometers.  Once drilling is complete, concrete is injected through a steel pipe into the well to create a casing through which the perforated pipe can be inserted. The top pipe is called the "injector well". The process is repeated several feet below for the botton pipe, known as the "producer well". Once complete, steam injection can begin. Over the well's lifetime, the sand in the well becomes less dense as the oil is removed from it, gradually increasing the area the steam accesses. Honestly, I don't know about the integrity of the localized well area. The potential of collapse doesn't seem to be an issue yet. SAGD steam injection occurs at a much lower pressures than other steam recovery methods or something like fracking. I'm sure the issue will come up as wells come to the end of their lifespan and have to be decommissioned. Depending on the size and density of the deposit, a SAGD well can last anywhere from 10-20 years. The first commercial well came online in 1996, at Cenovus' Foster Creek site. It's worth mentioning that over 90% of water used for steam injection is recovered when the resulting oil is treated. Many sites use limited groundwater or have annual limits placed on how much water they may take from rivers and other bodies of water, so it's in their best interest to ensure efficient water recovery. There is no concrete explanation for how the oil sands developed. The prevailing theory is that the oil was produced by the normal manner, being the result of organic matter being exposed to tremendous heat and pressure over millions of years. Eventually, the pressure became so great that oil was squeezed upwards into the sand deposits. Back then, Alberta was covered by a warm tropical sea. Oil sands deposits also exist in Russia as well, which seems to indicate that the deposits are a result of the relative location of the land masses on the planet That all being said, Venezuela has significant oil sand deposits as well. It's said Venezuela currently holds the largest proven oil reserves in the world. In terms of affecting life on the surface: it is often quoted up here that the indigenous people of the Athabasca region used bitumen to waterproof their canoes. I don't think it really affects wild life all that much. At least until humans showed up

|

|

|

|

How many people do you know who bought a big rear end truck and are now laid off and can't afford the payments?

|

|

|

|

Not many personally but I'm sure there are lots. Most people I associate with are other people in operations. Fortunately for us, we're last to go in a downturn such as this. If we're not working, it's because they company has suspended operations. Not likely to happen. The roads are noticeably emptier though.

|

|

|

|

How's the money?

|

|

|

|

Which part of Newfoundland are you from?

|

|

|

|

I've heard drugs and prostitution are endemic in Fort Mac? True? If so, how bad is it out there?

|

|

|

|

photomikey posted:How's the money? Very good. It has to be in order to live here, both cost of living wise and because there are much more... attractive places to live. This is what I tell people back home: Fort McMurray is a lot nicer than you probably have heard or think it is. But it's still not very nice. FrozenVent posted:Which part of Newfoundland are you from? I'm from the other coast.

|

|

|

|

jot posted:I've heard drugs and prostitution are endemic in Fort Mac? True? If so, how bad is it out there? This is one of the more prevalent myths of Fort Mac. Maybe at one time it was bad, but it's really not true anymore. It's like any other city in North America. If you go looking for it, you'll find it. You learn pretty quick the places to stay away from, and there aren't even that many anymore since a lot of the more notorious bars have closed down in the last few years. The municipality is pushing hard to present a more family friendly image of Fort McMurray, and it's slowly working. It's taking time though , and old stereotypes die hard.

|

|

|

|

Does the weather have a big effect on the process flow of the plant? Is it possible to take advantage of the cold weather to make some of the separation processes easier, or does the weather just make things harder? How about the digging, when you're that deep underground is it the same temp all the time? Do you need different equipment depending on the season?

|

|

|

|

Cold weather can be very difficult to deal with. Although this last winter was fairly mild, temperatures still regularly dip below -30 C. Freeze-ups are very common. Fortunately, the majority of them are minor and easy to deal with. For example, we use lots of portable steam heaters. They're fans with an inlet and outlet to connect steam hoses to. They freeze up a lot, especially if the hose is connected to manifold with other steam hoses. If you're using a low pressure steam source (around 50 PSI) and have three or four hoses connected to the manifold, you're probably going to freeze a heater if you're not diligent in checking them. Process indication transmitters freeze regularly as well. Essential transmitters are enclosed in an O'Brien box, which insulates and heats the transmitter. Regular duties on a shift are ensuring good temperature in every O'Brien box. On a larger scale, most equipment won't freeze up because they're either running constantly and thus always generating heat, or because provisions are usually made for a strong, consistent source of heat (most often emergency equipment such as firewater pumps or diesel generators). Emergency firewater systems distribution will never freeze before it is used because the system is all dry pipe. This means that the distribution piping is pressurized with air to prevent water from ever entering it until it's needed. One thing that does happen more often than it should is pipeline freeze ups. Most piping is insulated and electrically heat traced, but if there's a dead leg (a branch of piping where fluid will sit motionless, usually due to poor valve placement) and the EHT fails, it will eventually freeze. This can be very bad, as freezing water expands and can rupture the pipe. Some equipment will benefit from cold weather however. Anything that uses ambient air (air compressors, gas turbines, boiler draft fans) benefit from improved efficiency due to the higher density of cold air, but it's not really something tangibly noticeable in the field. Any equipment that exists to cool something also benefits. Aerial coolers usually come in several banks of fans and blow ambient air at a process fluid passing above in tubes. Fans will often be turned off in the winter as you'll reach your temperature set point way sooner. I don't know too much about how cold weather affects the mining of bitumen as I've never worked in a mine. It probably sucks though. Definitely must harder on the equipment. I can't comprehend how much money a company spends just to maintain one heavy hauler. Remember though, oil sands mining is done on the surface. There are no mine shafts.

|

|

|

|

Is the job market over there still excellent enough to draw unskilled workers from around Canada? I'm in Toronto and can't find an entry level job. A friend moved to fort McMurray a few years ago to get paid a crazy amount doing unskilled work like cooking. Is that still going on or has the drop in oil prices ruined the previously saturated job market?

|

|

|

|

|

MoosetheMooche posted:Is the job market over there still excellent enough to draw unskilled workers from around Canada? I'm in Toronto and can't find an entry level job. A friend moved to fort McMurray a few years ago to get paid a crazy amount doing unskilled work like cooking. Is that still going on or has the drop in oil prices ruined the previously saturated job market? Sadly, I think those days are over, if only temporarily. A lot of those unskilled labor jobs are in construction, and with all the oil companies having halted expansion projects, a lot of those jobs are gone with it. The number of layoffs across the industry are substantial. Suncor laid off 1000 workers. Same with Husky. Nexen just laid off 400 jobs across North America and axed the head of their oil sands operations. ConocoPhilips, Shell, Syncrude, Cenovus have all dramatically cut expenditures. A lot of office people are gone, but a lot of contractors are gone too, and contractors are who you, as an unskilled laborer, would be working for. The local college, which works with industry to provide the theoretical education required for apprentices entering the field, has had companies pull out of their programs. Rumors are that the the power engineering co-op program, where students get 4-months class time and 6-months paid on-site experience have lost half of the work placements. The FinnTech program, a heavy equipment mechanics course sponsored by Finning has apparently also lost most or all of their placements. However, it won't last forever. Try to tune out the doom and gloom as the media portrays. It most certainly is an awful situation, and despite what I said earlier about operations being last to be cut, it's still a possibility. But like almost any commodity based industry, oil is cyclical. It's highly unlikely that oil will stay this low forever, and some economists are worried that the timing of low prices is very bad if we're to keep up with future demand. $150-200/bbl oil is no good for anybody unless you work in the oil business. My advice would be, in times like this, to get a trade or skill. It's probably hard for you being where you're at, if you say you can't find an entry level job, but if there's any way you can swing it and not cripple yourself financially, I'd say go for it. Pipefitting/steam fitting, instrumentation, and millwrighting are all valuable skills to have to have and can take you almost anywhere. Power engineering, which is what I did, is another good skill to get. There are plants all over the world and they all need operators and you can make decent to amazing money almost anywhere. Just look at the opportunity in the Toronto area should you want to stay there. It's not oil sands money but I expect most of these jobs will put you in the $45-65k/yr area right off the bat. Get some experience under your belt and when things pick up again, you'll have the necessary skills to jump in, get a better job and make more money. For me, it was important to get a skill that I could take with me whenever I decide to leave the oil sands. I don't want the ability to support myself be dictated by one industry in a relatively remote part of the country.

|

|

|

|

I live in Edmonton and have been considering getting a job in the oil patch as a backup in case I get laid off, though I've never really thought about it very seriously. Everyone says to make the big bucks you need to "get a trade". How do you actually do this? The technical institutions seem to want you to be sponsored by an employer while all the employers never seem to hire apprentices before the 3rd or 4th year. If I wanted to say, be an electrician and get a camp or plant job or whatever, what are some reasonable steps to take?

|

|

|

|

Poldarn posted:I live in Edmonton and have been considering getting a job in the oil patch as a backup in case I get laid off, though I've never really thought about it very seriously. Everyone says to make the big bucks you need to "get a trade". How do you actually do this? The technical institutions seem to want you to be sponsored by an employer while all the employers never seem to hire apprentices before the 3rd or 4th year. If I wanted to say, be an electrician and get a camp or plant job or whatever, what are some reasonable steps to take? Trade school is an option. Most junior/community colleges usually offer trades classes, like electrical, plumbing, hvac, etc. And those trade schools usually have job placement stuff, especially for apprenticeship trades. Alternatively, look into the union for the trade you want. IE the IBEW if you want to become an electrician. Your local should have information on joining and the steps you need to take, as well as being a place to meet contractors who would be willing to sponsor someone through their apprenticeship. how applicable is what you do to oil field production in crude? Like the offshore type rigs, or what they have in WV/TX? If the jobs in Ft McMurray dry up do you feel you'd have an advantage in trying to go to like, the gulf and be able to get a job there? Also, what do you personally do? I know you said you're a plant engineer, but do you oversee like the extraction of the oil from the sand? Is there a specific step of the process that you specialize in, or do you all oversee the whole production chain? Dr Jankenstein fucked around with this message at 00:14 on Mar 24, 2015 |

|

|

|

Poldarn posted:I live in Edmonton and have been considering getting a job in the oil patch as a backup in case I get laid off, though I've never really thought about it very seriously. Everyone says to make the big bucks you need to "get a trade". How do you actually do this? The technical institutions seem to want you to be sponsored by an employer while all the employers never seem to hire apprentices before the 3rd or 4th year. If I wanted to say, be an electrician and get a camp or plant job or whatever, what are some reasonable steps to take? Mostly what AA Is For Quitters said. Check at NAIT or SAIT, or even BCIT. A lot of programs basically just require a high school diploma and maybe some math or sciences. BCIT's Power and Process requires Math 12 or equivalent (Math 30 in Alberta) and Physics 11 (Physics 20). A lot of schools will have job placement stuff for practical experience. AA is for Quitters posted:how applicable is what you do to oil field production in crude? Like the offshore type rigs, or what they have in WV/TX? If the jobs in Ft McMurray dry up do you feel you'd have an advantage in trying to go to like, the gulf and be able to get a job there? I don't know what life is life on the rigs, but the way I see it, a pump is a pump, a heat exchanger is a heat exchanger, etc. There are many different designs but the operating principles are the same. There are constants across heavy industry that once familiar with, can take you wherever. There will always be something new to learn but the more knowledge and experience you have behind you, the faster you'll learn. That all being said, power engineering as a vocation is mostly a Canadian thing. Obviously plant operations is a thing in the US and other parts of the world, but historically they don't get the same level of training and legislative oversight as we do in Canada. There are legal requirements that certain posts require a certain level of certification to be operated. I think that may be changing though, and other countries are working to adopt a standard like Power Engineering in Canada Personally, I work in a steam plant. We operate several large steam generators that supply process steam to various users on site, as well as to drive steam-driven turbine-generators that power the whole operation. Most sites up here produce more power than they need and end up selling it back to the grid. Our main steam generators are very large - several stories tall, and can each can supply several hundreds of thousands of pounds of steam every hour. We also run the pumps that supply the boilers with water, several large air compressors for plant and instrumentation air, emergency diesel generators. Our job is to ensure everything runs properly. I like the post because it's versatile. Steam generating utility plants are used the world over, and experience in them is great for future job prospects. But I'd like to spend time in a process-oriented post because they're a lot different, if more specialized. Some common posts other operators might have up here include: Well-pads at SAGD sites: Don't know too much about what they do, but they work right at the well pads where steam is injected and oil comes out at SAGD sites Steam generation comes in many different forms. Natural circulation water-tube boilers are the work horse of the industrial world, and can be found almost anywhere. Combined generation (CoGen) is a common source of electrical power generation where one fuel source is used to make two output energies. For instance, you might burn natural gas in a gas-turbine to produce electrical energy, and use the hot exhaust gas to boil water. The steam created will be added to the header for usage wherever. SAGD sites make extensive use of Once-Through Steam Generators (OTSG). As the name implies, there is no water circulation in these boilers. Water enters in one end and exits immediately as steam. These are the most common suppliers of steam to well pads, and are popular because they don't require as pure of water as a circulating boiler, and the steam doesn't have to be completely dry. Water Treatment: The water that is used in boilers must be highly treated to both preserve the boiler tubes, and prevent impurities from carrying over in the steam which can damage downstream equipment. Froth Treatment: The initial processing phase of oil sand, through which a solvent is used to separate liquid and solid contaminants from the bitumen, producing a "froth" which is skimmed and sent for further processing Hydrogen Production: Reacts methane (the active fuel component in natural gas) with high pressure, high temperature steam to produce hydrogen gas Sulphur Recovery: Removes the nasty chemical impurity Hydrogen Sulphide (H2S) from oil and gas streams and converts them into elemental sulphur. Normally the sulphur is sold to the agricultural industry but the oil industry is producing way more than is viable to sell. As a result: Syncrude's infamous sulphur pyramids  Hydrotreating: Removes contaminants from petroleum fractions to prevent damage to equipment, and for a much higher quality end product. Hydrocracking: Reacts heavy oil fractions with (almost) pure hydrogen to break the oil down into smaller fractions. This is where the end product, synthetic crude, is produced in upgraders.

|

|

|

Carbolic Smokeball posted:That all being said, power engineering as a vocation is mostly a Canadian thing. Obviously plant operations is a thing in the US and other parts of the world, but historically they don't get the same level of training and legislative oversight as we do in Canada. There are legal requirements that certain posts require a certain level of certification to be operated. I think that may be changing though, and other countries are working to adopt a standard like Power Engineering in Canada I didn't realize power engineering was a Canadian thing. It was so focused on when I went through Engineering in Calgary, I thought it was just one of the two things paths you did as an EE that could go into industry. Power or Electronics. I worked briefly on a sagd plant that hasn't started operating yet and what "power engineering" I did there wasn't worth poo poo. I don't really have much to ask other than: is there anything to do up there aside from hunting and drinking? I guess anything outdoorsy. Do those sulphur pyramids smell? I never really got close to any, though I think there's an agricultural plant near drumheller that processes a lot of sulphur and that stinks.

|

|

|

|

|

It's engineering in the same sense that somebody running a train is called an engineer. It has very little to do with actual engineering, although if there was a proper analog it would be mechanical engineering. The regulatory body in the province, ABSA, offers a reduction in certification time if you have a mechanical engineering degree. I think drinking is more of an Alberta thing than specifically just a Fort McMurray thing. Either way, off the top of my head, there are at least seven liquor stores on the 4 KM stretch that is Franklin Avenue, the main street in downtown Fort McMurray, not to mention several bars and pubs as well. In terms of what there is to do around here: not a whole lot if you aren't into outdoorsy stuff. There's hunting, fishing on the Athabasca, a few golf courses, camping. The stereotypical "I work in Fort McMurray and have too much money" snowmobiling and ATVing. There's an artificial beach at Gregoire Lake about 30 minutes out of downtown. There's Vista Ridge, which has a little ski hill that operates in the winter and a WildPlay Elements Park in the summer. There are lots of little events put on throughout the year. Last summer there was a "Sustainival", a carnival run on green energy (ironic, I know). Then there's MacDonald Island. MacDonald Island is an absolutely MASSIVE recreational center downtown. It has a couple of skating rinks, a curling rink (where the Grand Slam of Curling is currently being held, if that's your thing), indoor soccer, a gym, the public library, a pretty awesome swim park, a golf course, baseball diamonds, tennis courts, an indoor playground for kids and an adjoining child mind center if you need somebody to take care of your kids while you work out. Here's a video about it if you want to see more.  They're also building a sports stadium called Shell Place right next door and have been advertising the hell out of the Northern Kickoff, a CFL game featuring the Roughriders and Eskimos to inaugurate the park's opening. The best part about Mac Island is that for a $50/mo membership you get access to the gym, swim park, discounted sports and fitness programs, etc. When you consider it costs the same or more just for a gym membership, it's totally worth it. EXCEPT the downside, which is that half of Fort McMurray goes there which can make it absurdly busy, and if they ever hold a trade show, which they do several times a year, it can be a nightmare to find parking. Jyrraeth posted:Do those sulphur pyramids smell? I never really got close to any, though I think there's an agricultural plant near drumheller that processes a lot of sulphur and that stinks. I've never been close to the Syncrude ones, but I imagine they do. I know hanging around sulphur plants can be pretty smelly. H2S is even worse though. Smells like rotten eggs. Until it doesn't...

|

|

|

|

Carbolic Smokeball posted:I've never been close to the Syncrude ones, but I imagine they do. I know hanging around sulphur plants can be pretty smelly. H2S is even worse though. Smells like rotten eggs. Until it doesn't... The ... here is "and then you die"

|

|

|

|

Carbolic Smokeball posted:I've never been close to the Syncrude ones, but I imagine they do. I know hanging around sulphur plants can be pretty smelly. H2S is even worse though. Smells like rotten eggs. Until it doesn't... I work as a well tester out of Grande Prairie and deal with H2S almost every hitch I do, it really does smell like poo poo. It's kinda weird being under supplied air taking samples and thinking man if I took off my mask I'd be dead.

|

|

|

|

Have you guys been experiencing a slowdown lately? I work in the Bakken Oilfields and theres layoffs everywhere and a lot less work for me.

|

|

|

|

EAB posted:Have you guys been experiencing a slowdown lately? I work in the Bakken Oilfields and theres layoffs everywhere and a lot less work for me. Yeah it's been slow for field work. We're going through layoffs, luckily having 3 years experience saved me from the current rounds. We let go enough people to keep the core group of experienced people relatively busy, but it's a far cry from last year of doing 24 on 4 days off for 5 months. Unfortunately you can't walk in the front door and be hired on the spot anymore. Part of the problem is there's a lot of companies offering the same services which is fine in the busy days but when it slows down like this you have 6 companies bidding on the same contract.

|

|

|

|

Yeet posted:I work as a well tester out of Grande Prairie and deal with H2S almost every hitch I do, it really does smell like poo poo. It's kinda weird being under supplied air taking samples and thinking man if I took off my mask I'd be dead. I hate packing up, although I've never used SABA except in training. Now I don't really do either because there isn't much need to in utilities plants. EAB posted:Have you guys been experiencing a slowdown lately? I work in the Bakken Oilfields and theres layoffs everywhere and a lot less work for me. The whole city is hurting for sure. Roads are bit emptier, our absurd house prices are coming down, as is rent people are trying to charge. When I moved here I had to have my car inspected as the required by the provincial government for all out of province vehicles looking to be licensed in Alberta. OK Tire has had a sign on Franklin Ave since I've been here advertising its pricing for OOP Inspections. $260, which is roughly the going rate in Fort Mac. I drove by it a few days ago and it now says $185. Businesses like grocery stores and fast food restaurants used to constant issues maintaining staffing levels. Not anymore. Lots of help wanted signs that have been in windows for years are gone. Pretty much the whole city has been suffering as a result. But it's all a part of being a boom town. The party doesn't last forever. Don't tell city hall though. Anyways, I can't believe I forgot this when talking about roles operators take in industry Control Room Operators:  These guys work in the control room. They sit in big comfy chairs and look at computer screens all day. Sound like the best job in the world? Depends who you ask. Some people find the responsibility very stressful. Others find it horrendously boring. But some people thrive and are very good at what they do. The screens display real-time information about the current operating condition of the plant. Transmitters located in the field report back to the control room via the distributed control system, or DCS. The panel operator uses this information run the plant at large, watch for operational trends and irregularities, and conveys this information to field operators as is needed. Proper communication between panel and field operators is of utmost importance. He's your guide in the field if something needs to be done. Conversely, if you're working on something in the field that will affect the process in any way, you'd best tell him that you're going to do it before you do it, because to him the difference between something being normal and an upset condition is knowing that the field operator is working on that system.

|

|

|

|

This was very pleasant breakfast reading. You answered a lot of my questions about life at Fort McMurray, so if you don't mind a broader question, I'm curious -- how do people in the industry see the future of tar sands? Basically that once prices go up again we'll be begging for that sweet, sweet bitumen, oh god why didn't we build a pipeline? You said there's an expectation that we'll be at 150 in the medium term. Another question: is fracking also used in Alberta? What are the issues from your POV in comparison to oil sands and drilling in general? Can you clarify what makes fracking unique? Thanks!

|

|

|

|

They say that the reason that SAGD has exploded in the last 10-15 years is because high oil prices finally made it viable, especially for small/medium size players. Diluted bitumen is a much lower value product than synthetic crude oil when compared to West Texas Intermediate, which is the benchmark that we compare SCO to. Of course, the low price producers get for dilbit is offset by the savings achieved by not constructing and operating an upgrader. There are lots of small sites in the area that are only SAGD, and sell their bitumen to sites with upgraders that aren't being run at full capacity. So as conventional oil pumpjacks and platforms run dry over the next several decades, and demand for oil increases as predicted, as will the price, making unconventional methods of extraction economically viable as what happened with SAGD. It's only speculation that oil may hit $150 or more. At this point it's anybody's guess. Different economists have different view points and many of them are viable realities. Some say we'll never see oil over $100 again. When I said $150-200, I had in mind a few articles I've read recently warning about the danger of not properly investing in new projects today. It's anybody's guess what will happen, but with my limited expertise on the economics of oil prices, I say it's highly unlikely that we WON'T see oil back over $100 in the next few years. I don't know too much about fracking, so some of what I say may be wrong or only partially correct. Fracking is a relatively small industry in Alberta, and most of it takes place in the southern portion of the province. It's similar to SAGD in that horizontal wells are drilled deep underground in order to access the oil and in that the plant footprint is very small, but the method of extraction is different as they're accessing different kinds of oil. Shale oil is come from rocks embedded with kerogen, whereas as the oil sands is literally sand that has been saturated with oil. SAGD is a slow, constant process. Steam is continually added over the lifespan of the well, and changes in injection temperature and pressure occur slowly as the well depletes to maintain consistent yields, whereas fracking is done by pressuring a liquid to several thousands of PSI to fracture the shale and release the oil and gas. I could be wrong, but as far as I know, the cost per barrel is lower in fracking, but the wells yields drop substantially after fracking begins. SAGD is more consistent over its lifespan. Fracking is controversial because of the potential impact the act of fracking has on the environment. It is largely believed fracking contaminates ground water and can trigger earthquakes. There is some worry that caprock in SAGD operations may fracture and cause oil to seep into groundwater sources, but most controversy to do with SAGD is as a part of overall oil sands development. Carbon intensive, uses lots of water (although most water is recovered and reused), waste byproducts, etc. Carbolic Smokeball fucked around with this message at 01:59 on Mar 26, 2015 |

|

|

|

Carbolic Smokeball posted:They say that the reason that SAGD has exploded in the last 10-15 years is because high oil prices finally made it viable, especially for small/medium side players. Diluted bitumen is a much lower value product than synthetic crude oil when compared to West Texas Intermediate, which is the benchmark that we compare SCO to. Of course, the low price producers get for dilbit is offset by the savings achieved by not constructing and operating an upgrader. There are lots of small sites in the area that are only SAGD, and sell their bitumen to sites with upgraders that aren't being run at full capacity. So as conventional oil pumpjacks and platforms run dry over the next several decades, and demand for oil increases as predicted, as will the price, making unconventional methods of extraction economically viable as what happened with SAGD. Awesome. Thanks for taking the time.

|

|

|

|

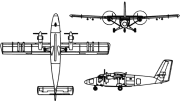

Pharnakes posted:How do you dig those horizontal tunnels through the sand? Is the oily sand so sticky it doesn't need much support? I can see how you could put in a perforated pipe for the steam delivery, but how does the recovery pipe collect the oil without collapsing? Doesn't the process disturb the sand and result in the tunnels trying to collapse once the oil has been leached out? I'm a drilling engineer so I can better answer some of this. I don't have any SAGD experience but I do have extensive horizontal experience. Basically it come downs to steel being one of the most amazing materials on earth. The well is drilled vertically to about 600' above the target. A downhole motor is then added to the bottom hole assembly with a bent housing. The downhole motor functions like a turbine, taking energy out of the drilling mud that is pumped to clean the hole and turning it into torque to turn the drill bit. When the bent housing motor is not rotated from surface and the bend is held in a constant direction the motor will drill an arc in the direction that it is pointed (the direction is referred to as toolface). You can see here how it works:  So the motor is oriented in the direction that is desired and not rotated from surface (this is called sliding). Generally horizontal wells have their curves drilled at 10-15 degrees per 100' so it is not a drastic turn for the drill string. The steel is more than capable of bending around that curve because its length is so much greater than its diameter (750-1000' around the curve compared to 4-5" in diameter). Once the bit reaches 90 degrees off of vertical the string is rotated and only slid when it is necessary to keep the well track on plan (various geologic and other forces conspire to push the bit off plan). The trick with SAGD is that the wells need to be drilled at a constant distance from each other. So once the first well is drilled, a very powerful magnet is placed in the well and the downhole measurement tools in the 2nd well can measure the magnetic field strength it detects and you can then model the distance between the MWD tool and the magnet.  SAGD drilling is really interesting to me and is really on the cutting edge of directional drilling. Directional drilling is glorified dead reckoning. You stop every 100' and measure your deviation off vertical and compass direction. Then you interpolate the points in between. The errors are cumulative. So the key in SAGD drilling is minimizing your ellipse of uncertainty and actually making sure the wells are the proper distance apart. That's where the magnetic rangefinding comes in. (Edited to not nuke tables from orbit) ch3cooh fucked around with this message at 02:31 on Mar 26, 2015 |

|

|

|

drat, that's some cool stuff. Thanks for the post.

|

|

|

|

I knew a guy that got hired literally from a phone interview, for a middle management type job, with zero experience or even an understanding of the business. Is that sort of thing still common, or was it really only happening when they needed people NOW (mid 2000's) He also told me once that his company will buy a brand new pickup truck, run it 24/7 for about 6 months and then get rid of it for another brand new truck.... how common is this across the industry?

|

|

|

|

Inflation adjusted, the average price of oil has typically been around the $40 to $60 range. So, market analysts think that although the volatility will end sometime and the price becomes more stable, the days of $100 or even $80 oil are long gone. In your opinion, how many capex projects will remain permanently cut if oil remains in that 40-60 range, versus the ones being put on hold until the price stabilizes?

|

|

|

|

I visited Ft McMurray for work a couple of years ago. It's like any remote mining town, except instead of the roads being covered in red dirt, they're covered in black crap. I've been right next to those sulfur pyramids at Syncrude and they don't smell at all, because it's elemental sulfur and isn't particularly volatile. My one Ft Mc story is that I stayed in a hotel downtown right next to a new car lot. One evening I went for a walk and cut through the car yard and found a torn open penis pump box discarded on the ground. It wasn't just opened, it was literally ripped open. Like the guy who opened it wanted his penis pumped RIGHT NOW. 10 yards from a main road. In between 2 giant pick up trucks. I GTFO.

|

|

|

|

Sappo569 posted:I knew a guy that got hired literally from a phone interview, for a middle management type job, with zero experience or even an understanding of the business. Mid 2000s, definitely. They were expanding like mad and so desperate for people they were hiring basically anybody. Plant operators especially. If they could squeeze you in without a PE ticket they would. That was all before the 2008 crisis. Nowadays unless you know somebody you need a 3rd Class certificate to even get your resume looked at (4th class being the lowest level) regardless if the position legally requires it or not. It was getting to be like that for a while before the oil collapse though. Too many college grads fresh out of school with 4th Class tickets and no experience. I don't know about the truck thing but I can totally see it happening. Most oil sands projects are notoriously bloated Meg From Family Guy posted:Inflation adjusted, the average price of oil has typically been around the $40 to $60 range. So, market analysts think that although the volatility will end sometime and the price becomes more stable, the days of $100 or even $80 oil are long gone. In your opinion, how many capex projects will remain permanently cut if oil remains in that 40-60 range, versus the ones being put on hold until the price stabilizes? I know next to nothing about the inner workings of giant businesses, and I have no idea about which projects will be cut forever. New projects are a long and expensive process before ground is even broken, so I can't imagine any project that's had the engineering work already done will be shelved permanently. However, I can say first hand that when oil is high, companies get bloated. They spend money like crazy because they can, and it doesn't really impact their bottom line. The truck example above is totally within the realm of possibility. $50 oil isn't the death knell that the media is making it out to be because it's been even lower before and companies still made money hand over fist. A dramatic oil price slide like this one will cause things to tighten up. Unfortunately, a lot of people are put on the chopping block and layoffs happen. But for the overall health of the company and the people who stay, it's probably a good thing. Once prices stabilize for some time and they're able to take everything into account, new projects will pop up again. I've heard lots of guys who have been here for 20+ years comment on something to the effect of "We were making tons of money back when oil was $30 a barrel. $50 should be no big deal" But as I said, lots of bloat over the years. Efresh posted:My one Ft Mc story is that I stayed in a hotel downtown right next to a new car lot. One evening I went for a walk and cut through the car yard and found a torn open penis pump box discarded on the ground. It wasn't just opened, it was literally ripped open. Like the guy who opened it wanted his penis pumped RIGHT NOW. 10 yards from a main road. In between 2 giant pick up trucks. I GTFO. Ahahah that's awesome. There's a sex toy shop about a block down from Alberta Motor Products, which is probably the lot you're referring to. That's probably where it came from. I haven't seen anything that crazy, but I can believe if it happened, it was on Franklin Ave.

|

|

|

|

Thanks for the answer, here's another one I've heard from folks. Basically people are making boat loads of money, like guys used to working construction jobs for $30-40k suddenly making $150k, so everywhere you look are jacked up super bro trucks. Apparently any bar you goto is packed with thirsty gf's and wives of these dudes, cause they work so much and are never home.

|

|

|

|

Carbolic Smokeball posted:Ahahah that's awesome. There's a sex toy shop about a block down from Alberta Motor Products, which is probably the lot you're referring to. That's probably where it came from. I haven't seen anything that crazy, but I can believe if it happened, it was on Franklin Ave. Yes it was pretty much opposite a sex shop, as was the hotel I think? Just did a google and I'm pretty sure I stayed in the Merit Suites on Franklin. We sell into the mining side. How do the producers decide whether to mine or use your steam injection process? It seems like mining must be exponentially more expensive due to the requirement for crushing, wear on hydrotransport equipment and need to dispose of tailings.

|

|

|

|

I just wanted to thank you for this thread, I've been fracking in North Dakota for 5 years and have always wondered about the oil sands guys. Sounds pretty similar to what I do in a way.

|

|

|

|

Efresh posted:Yes it was pretty much opposite a sex shop, as was the hotel I think? Just did a google and I'm pretty sure I stayed in the Merit Suites on Franklin. Mining tends to be about on par with SAGD cost wise. SAGD still has high maintenance costs and also requires purchasing the natural gas to fuel the boilers. Additionally mining offers the advantage of much higher recovery factor, recovering ~90% of OOIP while SAGD recovers 30-50% of OOIP. The main driver of mining vs SAGD is depth. Mining is only possible for deposits less than 200' below ground level. SAGD meanwhile has been used for deposits down to over 1000' below ground level.

|

|

|

|

Sappo569 posted:Thanks for the answer, here's another one I've heard from folks. Yeah, there are a LOT of trucks in Fort Mac, jacked or not. It's a pain in the rear end to get around sometimes, especially in parking lots because these trucks take up so much room. Add in winter, which obscures parking lines, and be prepared for 4-5 months of "If that rear end in a top hat had just parked two inches closer to the next guy I could park. They built a new strip mall in one of the new developments in Timberlea and parking is an nightmare there as well. A sad reality about our society is while we bemoan the high levels of consumer debt, we don't really do anything to encourage proper money management skills. As a result, there are a lot of people all over the place and at all income levels with really bad money management skills, and combined with a consumerist society that pressures people into buying EVERYTHING, it creates a lot of issues. As a result, you get those people you mentioned, who come here and make three or four times what they're used to and spend like they make way more than they are. So you do see jacked up trucks driving around town with ATVs and snowmobiles in the back on a regular basis. You see $70,000-80,000 trucks and Escalades regularly. People aren't shy about talking about how much money they made last year. It's not taboo, because everybody is making lots. But combine that with a high cost of living (housing, renting, services, eating out, etc), it's easy to see why there are people who make $150k a year and are broke. Or people who are managing so many debt sources that they'll never be able to leave. Or likely, as what just happened in the downturn, people who are facing unemployment, or cutbacks at work that they were relying on to make ends meet creating more debt burden. The prevailing attitude up here with young people is "What if you die tomorrow?" Well, I've worked with guys here in their 60s who had the same attitude. Tired guys with failing health who should have retired ages ago but are forced to work because they have no choice. Many people up here are divorced and paying child support as well. The other problem I have with that mentality is that for the most part, people make enough that they can save a substantial portion each paycheck and still have a great time. I didn't mean to get rant-y and preachy, but that's the reality of what can happen to people up here. However, there's another side to the coin. There are just as many people up here who are the opposite. They work hard to support their families, putting away money for their children and themselves, live a modest lifestyle with affordable (and still quite nice) vehicles, and still are able to take multiple vacations a year to DisneyLand or Vegas or Mexico or wherever. They don't rely on overtime or bonuses to get through the year. If they lose it, they may have to cut a vacation or something, but they won't be destitute. As for the bars, I don't really know because I don't go to the bars very often. Fort McMurray has a fairly high male-to-female ratio (about 58:42) so there are LOTS more thirsty dudes than chicks, especially when they come in from the camps.

|

|

|

|

Efresh posted:Yes it was pretty much opposite a sex shop, as was the hotel I think? Just did a google and I'm pretty sure I stayed in the Merit Suites on Franklin. Yeah, Merit is the one right across the street from Source Adult. Keyano College is right on the opposite corner. The strip club is also right across the street from Keyano, amusingly enough. Mining in the oil sands is seen as a thing of the past. There are actually only six currently active mining sites in the oil sands right now. Suncor, Syncrude, Canadian Natural Resources, Imperial Oil, and two for Shell. With the exception of one new entry, all proposed mines are expansions of existing ones by one of those companies. The companies that do run them will continue to run them because they already have the processing capabilities and mine equipment at their disposal. But the vast majority of the investment is in SAGD, and is likely to continue to be that way. This PDF is a map of the oil sands and all existing, approved, and proposed projects. You can see how many proposed and currently constructing projects are thermal projects.

|

|

|

|

|

| # ? Apr 25, 2024 08:50 |

|

I hope my rant didn't scare everybody away. Rumors are abound that Suncor is ending its hiring freeze. This is probably a good thing for the oil industry as a whole but it's hard to tell. Suncor is the largest oil company in Canada and they have a hand in every portion of the market, from production to refining to retail sales. They have a lot more flexibility than most oil companies in the oil sands. Still, it's encouraging.

|

|

|