|

My return to Volvo ownership ideas always involve RWD wagons, but sometimes I consider what having a 780 might be like. They're not very common though.

|

|

|

|

|

| # ? Apr 25, 2024 22:42 |

|

Owning a 780 will be like owning a 740 with reeeeeeeeeeally expensive and hard to find bumpers, spoilers, and light lenses. And forget about the glass, bust any window and total the car. Fixed the boost leak, one of my clamps didn't slide on the silicone and was egg shaped, leaving a small section un-clamped. Just enough to blow air out with a whistle. Pretty sure this is the noise culprit: And this fixed it, although it's a temporary solution. It's over-stretched here and it's also part of the complete samco kit for stock tubing and I'd like to sell it off and recover some money, so it's coming back off. It was mostly due to the lower elbow being too short, amplified by my problem of the intercooler outlet being off of the factory location. Now I'm working on re-linking all my photos. Ugh. LloydDobler fucked around with this message at 05:58 on Jul 9, 2014 |

|

|

|

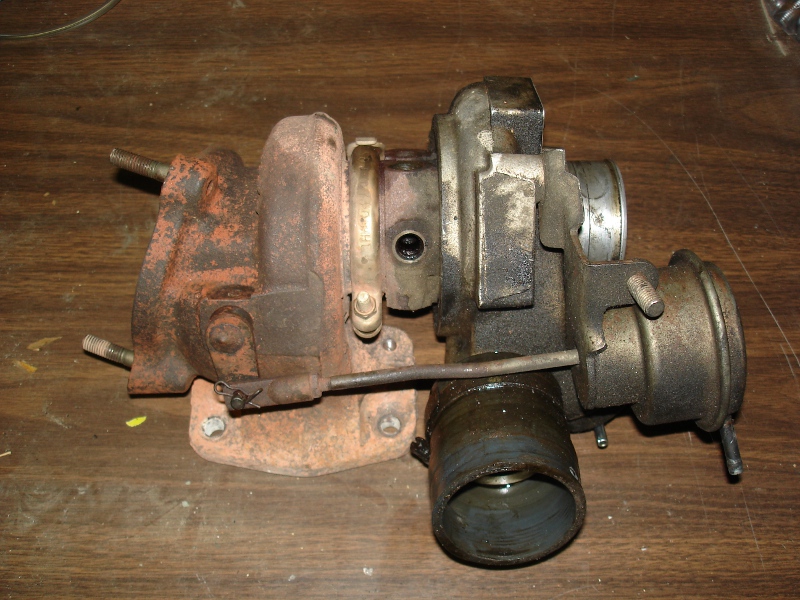

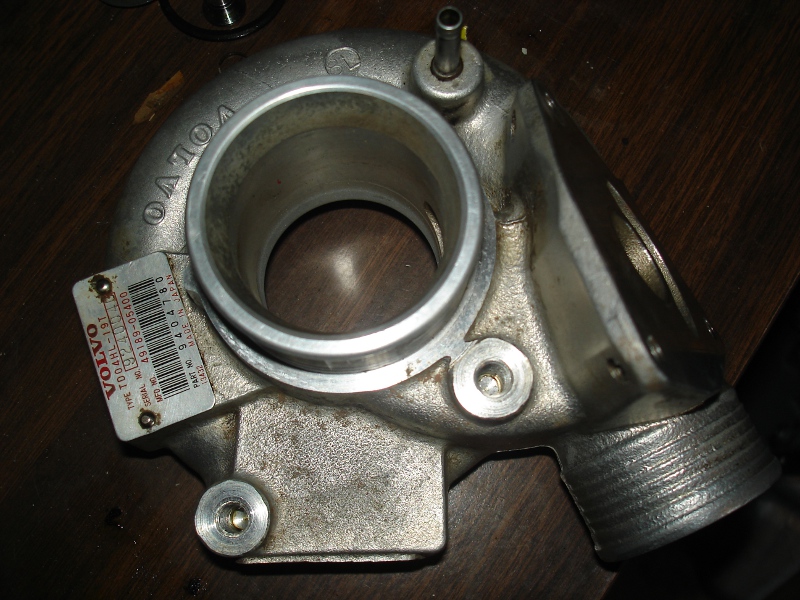

So I thought I was done with this car, but circumstance had the last possible mod I'd be interested in doing fall very affordably in my lap... Boom. Stock 19T from a 2000 V70R.  A bit on the high mileage side with some play, but zero evidence of the wheels rubbing on the housings. I'm gonna clean and rebuild it and then drop it in. I watched some youtube videos of how to rebuild turbos and it's super easy, I thought there was machining involved. I'm still deciding whether or not to upgrade the compressor wheel to a billet 19T or 20T wheel, I probably will just because I got the turbo cheap and it's about the max you can mod these cars without doing engine internals. I do need to go research and find out what to realistically expect from the upgrade.  And this is as far as I can tear it down as I don't own a large snap ring pliers. I'll pick one up this weekend. The cool part is that from everything I've read, the hot side is the same on all these so I can do the rebuild and then just stick this in my hotside that's on the car, none of those nasty exhaust bolts to deal with. I plan to get it installed and re-tuned before the end of the summer.

|

|

|

|

Glad everything is finally running smoothly, LD. Looking forward to what you can put down with the new turbo.

|

|

|

|

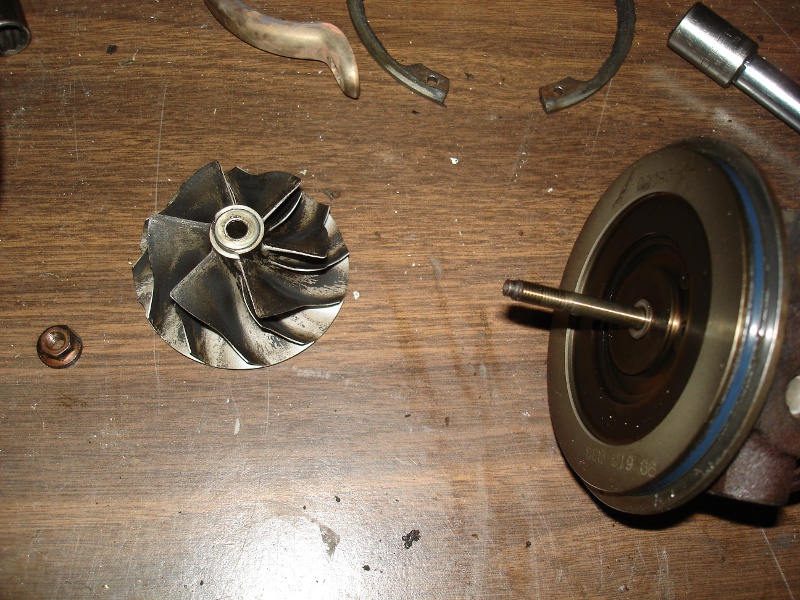

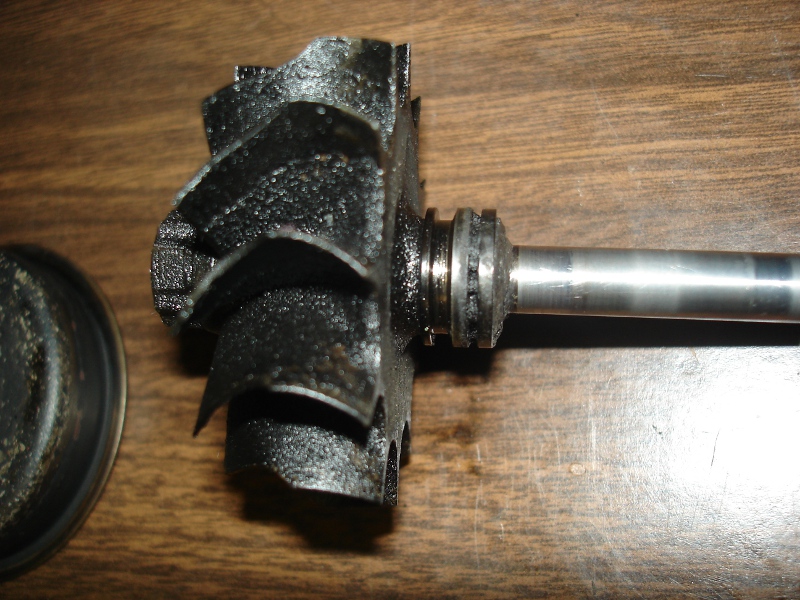

So last week I started tearing it apart, this thing is filthy: The dirty compressor wheel came off easily enough.  The turbine wheel and bearing section is really coked up badly, I couldn't even get the bearing off. The bearing was scored around the OD like it spun in the housing.  The o-ring wasn't even visible behind the layer of gunk built up in the compressor side.  Oil varnish and heavy wear on the thrust plate:  At that point I ordered a rebuild kit and dumped all the parts into a solvent tank to soak. Then the rebuild kit arrived yesterday! Much faster than I expected.  The compressor side parts came out really nice and clean, almost like new.  The compressor side of the center housing cleaned up pretty good too:  Not so much on the hot side:  This didn't come clean either, it's really hard oil coke I think. Either the engine was burning a lot of oil or the turbo was leaking a lot of oil.  Lots of gunk built up in the oil passages and on the sealing surface in here:  So then as I was cleaning, I went to blow out the water passage and it spit a whole bunch of powdery corrosion at me. It appears that the entire water jacket on this turbo is blocked off by something like stop-leak or some other corrosion. Air does not blow through it. It's a white powdery gunk that I can scrape out, but only so much as the water passages twist and turn inside the housing. Between that and the extremely hard buildup on the hot side sealing surface that I can't even scrape off with a knife, I'm wondering if this center housing is too far gone to use. I might take it to a motor shop and see if they can clean it out in a hot tank. Also the compressor bypass valve is toast, so I need one of those. I'm starting to think my best bet will be to just put this compressor wheel and cold side housing on my existing turbo, basically upgrading it from a 16T to a 19T, since the hot side is all the same anyway, and call it good. That or pull the whole center housing and rebuild it with the kit, but that seems like overkill on a turbo with less than 70k miles on it. I do also have a spare LPT turbo, I should pull it out and see if I can use anything from that. Ugh.

|

|

|

|

A little hard to tell at a glance, but that rebuild kit came with a upgraded thrust bearing, right?LloydDobler posted:Owning a 780 will be like owning a 740 with reeeeeeeeeeally expensive and hard to find bumpers, spoilers, and light lenses. And forget about the glass, bust any window and total the car. There are places that make custom glass, I had a friend get a brand new side window for a 1920s car that way. And the price wasn't unholy, if a bit more expensive than a normal window.

|

|

|

|

I'm liking seeing the turbo tear down and information. I have a td04 with shaft play. I can just get a rebuild kit and slam it in? I thought you had to balance these things when you open 'em up? I'm a bit confused as to what is serviceable and what isn't.

|

|

|

|

Nidhg00670000 posted:There are places that make custom glass, I had a friend get a brand new side window for a 1920s car that way. And the price wasn't unholy, if a bit more expensive than a normal window. 1920's tend to have flat glass. That's easy. when you're looking at the curved cast stuff, like most modern cars have, you're in real trouble.

|

|

|

|

Slow is Fast posted:I'm liking seeing the turbo tear down and information. From what I'm reading, if the wheels aren't damaged then they're balanced well enough independently that you really don't need to re-balance. Especially if you mark the vanes and reassemble in the exact same position. However, there are turbo balancing shops in every major metro area and they do it on the assembled turbo as far as I can tell. You take them the center assembly and they stick it in a balancing machine and spin it up.

|

|

|

|

Sorry if someone's already pointed it out but "nej" means no in Swedish, your license plate rules (and so does the rest of your car).

|

|

|

|

Cached Money posted:Sorry if someone's already pointed it out but "nej" means no in Swedish, your license plate rules (and so does the rest of your car). Someone did, and when I found that out I finally named this car "Not Satan". My daughter cracks up every time she says it. "So are we taking Not Satan to school today? Hee hee hee."

|

|

|

|

LloydDobler posted:This didn't come clean either, it's really hard oil coke I think. Either the engine was burning a lot of oil or the turbo was leaking a lot of oil. I ripped apart a TD04 from an LPT enginge this week to do a cartridge swap into my 99 xc wagon next weekend and the exhaust side is in similar shape. The race(is this the right term?) on the bottom of the turbine part of the shaft was pretty pitted like yours as well and the o-ring on the compressor side came out as a pile of gunk. I put all of it, sans turbine housing, into a bucket of simple green to soak this afternoon and we'll see how it goes when I pull it tomorrow. I marked the wheels but I'm not sure it really matters with a unit this small. A rebuild kit should be showing up soon. I enjoy your threads and detailed posts... please keep them coming.

|

|

|

|

Sure thing. I've never had any luck with simple green but everyone I know seems to swear by it so here's hoping. I did some more research last night and found that the 13T through the 18T all use the same compressor OD so the center housings are all the same... and the 19T and 20T are 2mm larger. So I either have to clean the 19T housing or machine the compressor pocket 2mm on the 13T housing. I'm gonna try to machine it first because it also has the correct coolant line ports which must have changed in 01 or so. I'll post photos if I'm successful.

|

|

|

|

I'd try CLR if simple green doesnt work for you. http://www.jelmar.com/CLRbasic.htm I used it to unclog a jeep heater core and it didn't explode and fart coolant all over my interior.

|

|

|

|

Slow is Fast posted:I'd try CLR if simple green doesnt work for you. loving John Wayne say it sucks, not sure I want to doubt him https://www.youtube.com/watch?v=z7FYPwRFDZI

|

|

|

|

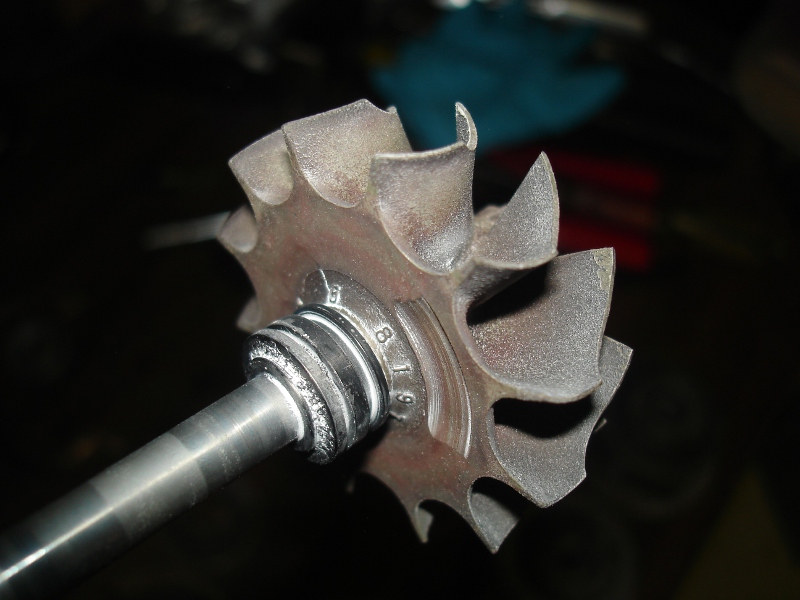

Here's the 19T vs 13T compressor wheel. The 16T will be in between. It's a bit surprising that these half millimeter differences change the turbo that much. Then again, at 100,000 RPM a millimeter clearly translates into several cubic feet per minute of flow. The turbine wheels are identical, I measured them to make sure.  The center housings are different only in this relief for the compressor wheel. 19T on the left, 2mm larger than the 13T-18T on the right.  So that leads us to tonight. I got this for $20 from Amazon:  And this from Sam's club for $10:  Let's get started!  My plan was to blast into the trash can to contain the mess, but no way, it went everywhere. So I took it outside. First pass, it did some damage but not as quick as I'd hoped:  As for rust and surface corrosion/contamination, it does a remarkable job.  The 13T impeller cleaned up pretty nice on the first pass:  The 19T, not so much. Need a combination of soda blasting and scraping to clean it up.  So far I'm impressed with the soda blasting, I went through less than 5 lb of soda (I bought 26 lb) but I had to refill my compressor 3 times just to get done what i got done. I think I'll take the whole can of worms to my workplace where we have a several hundred gallon tank on an industrial compressor, and I can spend some real time blasting the parts. I still have some carbon to blow off, but I think if I can blast for more than 2 minutes at a time I'll make a real impact on the parts. Stay tuned. At this point, I'm happy with how the 19T housing is cleaning up, so I'm going to try to machine the 13T housing only because it's less corroded and has the same ports as the plumbing on my car. But if I mess it up I don't care, moving one water line is not a problem.

|

|

|

|

I find myself wishing I went ahead and took the blasting gear with me today but at 7AM packing dirty clothes and baking soda and all that crap just seemed like a hassle, so rather than stay late soda blasting, I figured I'd try to see if our lathe at work could hold the center housing accurately enough. Well I got impatient and did it over my lunch break, so I could have finished soda blasting at the end of the day. The good news, the lathe dialed right in straight and true, and I was able to very easily open up the compressor clearance.  So now I have two 19T center housings, but one with the correct water piping ports blocked, and a lot less corrosion and coke buildup! It was very easy. All that's left is to finish blasting and cleaning the turbine and the back of this housing and I can rebuild, and then install my newer beefier turbo. But now through Sunday is when I have my daughter, so no staying late after work until Monday. Oh, and in other car related news, my 5 year registration expired on the oldie, so I went ahead and signed up for another 5 years...  I just need to stop loving around with this convertible so I can start a new thread about it. LloydDobler fucked around with this message at 04:40 on Aug 21, 2014 |

|

|

|

Hey I found your build thread! Did ard ever figure it out completely for anyone else who did the swap? Now I really really want another Volvo.

|

|

|

|

angryrobots posted:Hey I found your build thread! Did ard ever figure it out completely for anyone else who did the swap? I think he needed the correct ECU from his model year, I don't think the tuner was able to ever get the other (automatic?) ECU flashed properly or something. When he got the correct ECU in, it worked right away.

|

|

|

|

angryrobots posted:Hey I found your build thread! Did ard ever figure it out completely for anyone else who did the swap? I think he's gotten all the CELs out on certain years, but as far as I know he's never been able to get cruise control to work, even when you go to the trouble of wiring in the clutch switch.

|

|

|

|

So I soda blasted the parts some more but really didn't get them any cleaner. At least not anything worth uploading more pictures. I thought the center section could be balanced just as the rotating parts, but I talked to a balancing shop and they balance the turbo with the center housing assembled. Tonight I set out to assemble it. Starting with a pool of oil!  I poured oil in the oil inlet. Of course I spilled it everywhere but whatever. Better more than less. Gonna put on a smokeshow when I bolt it up though.  Installed the impeller side sealing ring.  Put the bearing in the housing, slid the impeller down, no problems.  Installed the compressor side o-ring:  Installed the compressor side bearing  Compressor side thrust bearing:  Tried to put the thrust plate in and couldn't, so I had to remove the o-ring, then it went in fine.  Put in the compressor side seal:  Put whatever this plate is on with the seal bushing, and put the o-ring back in:  Then I couldn't get the outer sealing plate on, the o-ring seal was too tight. So I decided to use the compressor wheel and nut to push it down. Unfortunately the inner seal ring did not compress into the plate as needed, I hooked the edge of it and it popped out. I gouged the center bore of the seal plate and bent the seal ring.  I also dinged up the seal bushing.  After a few minutes of thinking about it, I realized that I should have put the seal ring with bushing and shield into that plate first, then tried shoving it in the housing. I tested it on my old parts and it worked perfectly. Live and learn. I did some preliminary shopping and can't find anywhere that sells individual parts like that, I pretty much have to buy a whole new rebuild kit to replace the 3 parts I damaged. gently caress, $60 mistake. I've made bigger mistakes before. Live and learn. For now I will listen to angry music to fit my mood. https://www.youtube.com/watch?v=8a5Ciw9PSNQ LloydDobler fucked around with this message at 06:05 on Aug 28, 2014 |

|

|

|

Well, a couple weeks ago I got my second rebuild kit, and got it together. Much easier when you do it in the right order: Unfortunately this backing shield wouldn't work. If you look closely, right where it's bent, it's not relieved so it actually holds itself above the surface. A few seconds with the dremel would have solved that, but I was angry enough that I just used the old one from the turbo to begin with. It's not a wear item anyway. But it kept the snap ring from engaging, I had to take it apart again to figure it out. Both were like that. Quality.  I sent the turbo out for balance, and while I can't see any signs that they balanced it, they cleaned it far better than I could have. Looks like a bead blast finish.   I don't know if they took it apart or not, but at this point I don't care. It's clean and balanced and ready for installation!

|

|

|

|

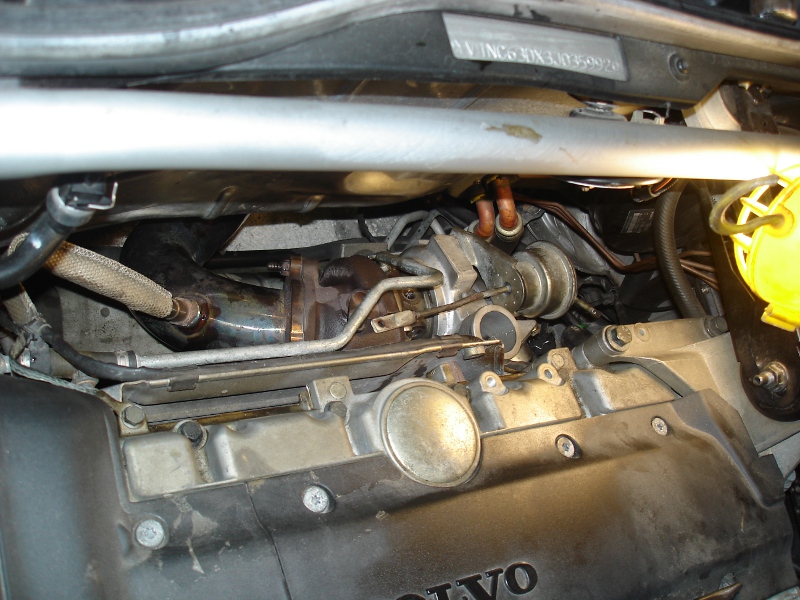

Alright, a few weeks ago I solvent cleaned the cold side:  Then I soda blasted it:   It doesn't quite dig in to the aluminum, as there are still some black spots of corrosion that didn't come out with anything, even wire brushing. I suppose I'd have to sand or bead blast to really get those out, but this is plenty clean for something that sits completely out of view in back of the motor. Reassembled cold side:  Then last week I dug in to replacing it. First of course is removal of all the hoses and connections.  In about an hour I had it out of the car. I wonder what pink on your hotside means? Am I running rich or lean or something?  Turbo housing pretty clean inside. I also checked this for cracks when the engine was out of the car, so far so good. The wetness is just coolant that dripped off the cooling line.  These added about 30-40 minutes to the job, for some reason everything on the back of my motor is corroded like this, it was the weirdest thing. They were like this at 39k when I got the car back in 2007. Nothing else on the car was corroded at all.  Anyway, I decided I didn't like them, and I have a low mile engine for my wagon sitting in my warehouse at work, so I snagged the oil lines off of it. Transferred the CBV and wastegate actuator off of the 16T, both are in way better condition than the ones on the 19T.  And one V-band clamp is all that holds the CRHA and cold side on to the car.  I did all that last week, and then came down with some annoying stomach bug so it wasn't until tonight that I swapped the new oil feed lines on and buttoned up all the intake tubing. Hooked up a boost gauge and took it out for a test drive. Pulls a nice hard 20 inHg of vacuum, and very quickly makes 17 psi with the existing tune. I was very careful though not to not have any boost until the engine was running over 3000 rpm, just for safety. It's high boost at low RPM that kills these motors, in the form of bent rods. So tomorrow I will call my tuner and schedule a time to load a new tune for this turbo. I will also discuss whether or not I need new injectors, as I've heard rumors that the blue injectors I have will possibly max out with the air this turbo can push. Or maybe it just means I'm stuck at a lower boost level. If that's the case then I will probably upgrade those too, considering how easy they are to swap. Nice weather predicted for the next 3 days so hopefully he isn't busy and I can get it done tomorrow or tuesday.

|

|

|

|

1. Jesus Christ this is ridiculous 2. Low 70's and zero chance of rain predicted for the next 7 days 3. What a great way to finish modding this car. I'll try to get some video of the boost gauge somehow, because it's nuts. This thing is basically dying to make boost at all times. John (JZW tuning) kept my car for a full day and not only dialed it in to peak at 22 psi and then level off around 20, in all gears INCLUDING FIRST, but he double and triple checked the a/f ratios and injector duty cycle to make sure I wasn't in danger of damaging my engine. He said he thinks this is about as hard as we can push the motor on stock internals, which is fine by me because it is really wicked fast compared to what it was. And I have no interest in opening up the motor. Basically between 2000 and 3500 it ramps smoothly up from zero all the way to 22, then levels off at 20, then at around 5000 it dips to 17 and holds there. I don't take this motor up over 6500 even though the redline is somewhere north of 7000. The torque peak is around 4k so I like to hover there. My buddy who just got a very nice all stock '97 850R took me to pick it up tonight, and on the freeway drive back he did the "honk honk go" signal at me, and I absolutely walked away from him. Like not even close. Like I had to ask him if he tried to keep up because it looked like he didn't. (It was 10pm, the freeway was empty, and we were basically doing 3rd gear bursts from 60 to 80 in a 75mph zone.) I really can't think of anything else I would do to this car. I'd like a big Brembo brake kit, but they are very un-affordable for this car, and the stock brakes work very well. So I'll only do that if I have money to burn or stumble upon a great deal. I do want to PDR this car, as it needs it, and at some point it needs minor paint work as the driver's door, hood, and front bumper are pretty scratched up. But again, that will come later. So for now I'm really, really done. My hard costs for this turbo upgrade come to $395 including the extra rebuild kit and re-tune. Now I can begin on the 122 5 cylinder swap, so I'll start that thread as soon as I get the motor pulled, which will happen very soon.

|

|

|

|

That car must be a blast. My old C70 manual with the regular IPD chip/intake/exhaust was fun, but it was a big car, so it really needed more power. The bigger turbo was on my "want" list. Enjoy it, you've worked hard enough for it!

|

|

|

|

|

| # ? Apr 25, 2024 22:42 |

|

Awesome, I'd like to see a speedo climb video or something. 20+psi in 1st gear, LAWL

|

|

|

EVERYWHERE

EVERYWHERE