|

My mower that seemed to be having trouble with the stator now won't start at all. It was sitting outside for about a month, and I charged it today, and when I turned the key the engine wouldn't even turn over. The headlights still come on and I'm getting a 13 volt reading from the terminals of the battery. What could be wrong?

NotNut fucked around with this message at 02:05 on Aug 10, 2022 |

|

|

|

|

| # ? Apr 20, 2024 04:34 |

|

NotNut posted:My mower that seemed to be having trouble with the stator now won't start at all. It was sitting outside for about a month, and I charged it today, and when I turned the key the engine wouldn't even turn over. The headlights still come on and I'm getting a 13 volt reading from the terminals of the battery. What could be wrong? Tap the starter with the HANDLE of a hammer (not the hammer part of the hammer). Might just be stuck. Past that I'd get a test light/multimeter on the starter to make sure when you're turning the key it's getting voltage. Could be the key switch, wiring, or the starter itself.

|

|

|

|

Motronic posted:Tap the starter with the HANDLE of a hammer (not the hammer part of the hammer). Might just be stuck. I'll try that, thank you.

|

|

|

|

Two issues: Small stand behind track loader. Its a "ramrod" brand. gently caress them by the way. I don't think I'll be reaching out to them for assistance because they're a bunch of scammin' rear end motherfuckers. Engine is a 3 cylinder Kubota Diesel Model: D902, non turbo. First issue is that it has a small solenoid to shut down the engine. Every so often that solenoid fails and the engine won't shut off, so we have to reach in and pull or push (I forget) the plunger by hand to kill the engine. When we take them off they smell like electric death. I don't think its a result of heat though as far as I can tell its in the factory spot and its not *that* close to the exhaust manifold. There is certainly other electrical brick a brack near the exhaust manifold and we haven't had issues with any of that. Anyone have any ideas if this is just a known lovely part? It seems like Kubota would have replaced it with something better if that was the case but who knows. Second issue is with the hydraulic oil cooler. When we first got the thing, the fan would come on at (some unknown but "hot") temperature, and after about a week of working, it stopped working. We bypassed the thermal switch to see if the fan would come on and it did. So we figured that the issue was the switch. Its a pretty small switch and had no identifying numbers/words on it to indicate manufacturer, part number etc, but I managed to find one similar from an ATV. Screwed the thing in, hooked it up and ran it for a while, fan didn't come on. Bypassed the switch, fan comes on. Take the switch out, hook it up, put a lighter under the little temp nub, fan comes on. Put it back in, and hook it up the way its supposed to be fan doesn't come on. The original switch was screwed in to a bushing (either aluminum or brass don't recall offhand) which was then screwed in to the heat exchanger. Admittedly when the issue first came up we didn't actually check the switch itself, we just bypassed it, fan came on and so we figured the switch was the culprit. Any ideas what the issue could be? The bushing seems unlikely as the culprit, but at this point who the gently caress knows. Currently its bypassed in such a way that the fan comes on when the key is turned to the on position, but while that may be fine in the summer, its not necessarily ideal in the winter.

|

|

|

|

im trying to decide whether its even worth trying to get an ancient old Wisconsin single cylinder engine on an ancident old ditchwitch self propelled chain trencher running again or whether i just attack the thing with a plasma cutter, welder and a visit to the tractor wreckers and convert the thing to a 3PL trencher to run off the back of the massey....

|

|

|

|

Back on this temperature sensor of mine. Its been a while since I actually looked at the machine but it Turns out there was a steel fitting going in to the oil cooler, then a brass bushing and then the sensor. The threaded part of the sensor seems also to be the "sensing" part of it. I got a new steel fitting, drilled it tapped it and put it in there and eliminated the brass bushing, which brings the sensor part of the sensor a bit closer to the oil. Still no dice. I ran the machine for a while with a bunch of accessories going, and then did some laps around the parking lot in it. I have a laser temperature sensor and checked various parts of the oil cooler before checking the new steel fitting. The oil cooler was 150+ freedom degrees while the steel fitting was around 120. Without being smart, the only thing I can think of is that the steel fitting is just enough of a heat sink that its not letting the "sensing" part of the sensor get to a high enough temp to close the circuit. Does that make sense? I guess if the machine was in actual use, then maybe it would get hot enough but I can't do that without starting to drill holes in the ground with this thing. The only thing I can think of doing now is getting a colder switch and seeing how that works. Any other suggestions? Points of view?

|

|

|

|

First thing i'd do is take the temp sensor, attach a couple of wires to it and hook it to a multimeter on continuity and then boil it with a thermometer in it. In oil if you need to get it over whatever moon unit it is that water boils at and make sure its actually closing at whatever temp you think it should be switching the fan on. From what i can see with a cursory google, most things say to keep your hydraulic oil around 70 deg c for maximum longevity in earth moving equipment. Tho we've got one of the Vermeer mini skid steers at work and thats just got the cooling fan for the hydraulic cooler wired directly to the ignition ON position, so as soon as you turn it on, it runs and then it turns off when you shut the machine down and its never given us any grief. I've got a fun little repair to work on. Back story - Honda GX200 motor coupled to a Onga dual impellor pump. Been used for about 5-6 years pumping water up from a dam to the storage tanks at the top of the hill- close to 80M lift so working pretty drat hard all its life and its probably moved in excess of 1.5M litres of water. It also gets put in a pump shed to move water around and provide fire fighting water in summer. Couple of months ago dad was moving water around with it while he was working in the shed and heard it start to run funny, then struggle, then died. Walked out to the pump shed and found this...   Pulled the pump out of the shed and undid the oil drain and about 2.5 litres of this stuff came out. Normal sump capacity is 600ml...  As far as we can work out, the ceramic seal pack that sits on the crankshaft where the pump housing bolts on failed, either due to being damaged from rust jacking of the crankshaft snout after the primary rubber seal failed, or just due to wear and age. This allowed pressurised water into the cavity between the pump housing and crankcase, which is sealed, and then because the crank case seals for the crankshaft are designed to keep oil IN, they dont keep water OUT and then it filled the crankshaft with water and turned the oil into custard. Problem is that its obviously been happening for a while, cos the crankshaft where the ceramic seal sits and the section in front of the crankcase seals were heavily pitted with rust. Tried to clean it up with emery paper in the lathe but no dice. A new genuine honda crankshaft is around AU$300 and is on backorder, and we really want this pump running before the weather starts to warm up and the fire risk starts to climb, and would rather not throw a chinese crank in it considering how hard it works moving water and how much of a PITA it would be to have it break down midway through pumping season. We have another identical, much younger, pump thats going to be put in the pump shed for fire duties, because we dont want to risk that not working when it absolutely HAS too, but we're going to try and repair the crank on this pump. Bought myself a kilogram of ER80S-D2 Chro Moly tig rods and some ceriated tungsten and took to the crank with the lathe and some carbide to clean it up below the rust pitting. Which was baaaad (hence why you couldnt just speedi sleeve it)  Gonna build myself a jig to hold it on the bench and support my hands, preheat the entire crank to 250c with the oxy and then lay a bead of TIG down the journals to be built up, rotate it 180, lay another bead, rotate it and repeat until its built up higher than needed, then back to the lathe, machine it down and polish it into spec. Basically we're about $60 in for the TIG rods and probably only $40-50 worth of gas, so if it fails its not a huge expense, but its also going to be really good opportunity to practice and get a LOT better at TIG welding! And Grinding tungstens inevitably... Im gonna go buy a silicone carbide wheel for my bench grinder...

|

|

|

|

Ferremit posted:First thing i'd do is take the temp sensor, attach a couple of wires to it and hook it to a multimeter on continuity and then boil it with a thermometer in it. In oil if you need to get it over whatever moon unit it is that water boils at and make sure its actually closing at whatever temp you think it should be switching the fan on. From what i can see with a cursory google, most things say to keep your hydraulic oil around 70 deg c for maximum longevity in earth moving equipment. Thanks for the insights. Currently thats the setup we have, when we realized the fan wasn't turning on we just hot wired it to the key switch. So now whenever the key is on the fan is on, but winter is coming and I was hoping to get this sorted before then. We probably don't need the fan running when its -20 out or whatever. I talked to a guy at the place we bring our stuff to for hydraulics work and he looked up a 120*F Hopefully I'll have time to hook it up and test it out this week if they don't send me out drilling. We have had shot loads of jobs postponed because we can't get locates so I've been spending a lot of time in the shop lately.

|

|

|

|

I have an old Toro 521 snowblower (model # 38056) with a Tecumseh 5hp engine (not entirely sure exactly which model, possibly 640084B). This winter, while happily blowing the snow, it stopped and hasn't started since. Usual culprit is crap in the carburator but that seems fine and it won't even start on ether (which it always used to do even when the carb wasn't carbing). It has good compression and seemingly some kind of spark (plug visually looks decent and there is a spark), but it doesn't fire at all no matter what I do. I think I noticed one single successful combustion when messing with it, but that's it. My best guess is to throw a new plug in, and failing that, a new coil. I have no way of telling how "good" the spark is, but an old crappy coil or some such is the least bad guess I have as to why it would stop working suddenly like that. Is there anything else I should be checking out on this thing? It's maybe not the snowblower I want but it's the one I deserve, and I'd just like to keep it running until it is clearly dead beyond rescue. It needs a new pull starter (and a replacement carb just because cheap and easy), which I'd really only want to do if I can get the engine running first.

|

|

|

|

Fuel air spark You have air (probably) and spark (confirmed) Maybe dump the gas, let it (and any water) evaporate overnight with the cap open and start over with fresh fuel. Also maybe pull the air cleaner and validate it's not clogged with mouse turds and moth eggs or whatever. Once it starts and runs for 30+ seconds reattach the air filter. Remove the muffler and visually inspect, then reattach

|

|

|

|

Has there been a loss of compression? Stripped cam gear? Is it a flathead?

|

|

|

|

wesleywillis posted:Thanks for the insights. Currently thats the setup we have, when we realized the fan wasn't turning on we just hot wired it to the key switch. Also, to get back to this, I hooked up the 120degree switch ran the poo poo out of it for a while and it worked! Fan started up when it got hot enough.

|

|

|

|

Hadlock posted:Fuel air spark I had just the "naked carb" on there and with fresh gas in it (had it drained and cleaned first just to make sure that wasn't the culprit again), and tried it multiple times with engine starter spray stuff (not sure if it's ether or what, but it has always made the engine go when it has had carb issues). Which to me seems like not a fuel issue. Fuel, air, compression and spark all seem to exist, but the bastard still won't run. I can't say for sure how good the spark is though. It is there, but maybe it's just not angry enough? wesleywillis posted:Has there been a loss of compression? I checked with a compression tester when I had the plug out, forgot the exact number but it seemed perfectly normal and generally sounds like an engine with compression when I crank it (since the pull starter is broken, I've been using a power drill which spins it decently fast, and would reliably start it back when it worked). It is a flathead, yes (haven't pulled the head off, but it sure looks like one). If the cam gear was stripped, wouldn't that cause poo poo compression if things had gotten out of sync? Given there's many months until I'd expect any snow, maybe I just gotta pull it apart and see if I can find brokenness (and if it's hosed enough just get a new machine).

|

|

|

|

ionn posted:

If the cam gear stripped, or broke or whatever while the valves just happened to be closed then it might give decent compression numbers while cranking. If you've confirmed fuel (ether) I'd try with the coil or magneto or whatever it is. Maybe the spark is just super weak.

|

|

|

|

By ďnaked carbĒ you mean you had the carb blown apart and rebuilt, right? Pretty much every small engine Iíve touched in the past fifteen years has needed it due to varnish and sludge clogging all the metering jets and the fuel needle getting stuck closed.

|

|

|

|

wesleywillis posted:If the cam gear stripped, or broke or whatever while the valves just happened to be closed then it might give decent compression numbers while cranking. I'll probably take it apart enough to fiddle with the ignition coil (I'm assuming it's a magneto because derpy simple engine), and if that doesn't help, keep wrenching deeper until I find something suspect. Stripped cam gear would probably mean a new machine (parts are likely unobtainium here), but ignition stuff seems simple and cheap enough to replace. I'd just rather not pull apart stuff I don't need to, since while no gaskets/seals seem to leak right now I'm sure they will be more than happy do so after the sealing surfaces see daylight for the first time in decades. MrYenko posted:By ďnaked carbĒ you mean you had the carb blown apart and rebuilt, right? I just meant I had no air cleaner or anything on it, but the whole carb has been taken apart and cleaned a couple of times (including now, even though I'd done it recently I wanted to be sure that wasn't it). I didn't remove all the little pressed-in bits, but I've cleaned out all the jets/needles/channels that screw apart or where it's possible to blast carb cleaner and compressed air and poked thin wire through the tiny holes. Carbs are loving dark magic to me, though this one seems just barely comprehensible and as far as I can tell seems alright (though it certainly wasn't when I bought it). If I can make the engine run on ether I might replace the carb just because it's dirt cheap to do, and some parts seem a bit worn out (mangled screw heads and some slop in the choke/throttle levers and such).

|

|

|

|

Small engine carbs are actually super simple. THeres like one jet and a float with valve and fuel bowl. If you've already taken it apart and cleaned it then its probably fine. Especially if it was running and then died. And also if you've dumped some fuel right in it and it still won't start.

|

|

|

|

Well, for the first time in ~20 years, my old reliable, unkillable generic ~lawnmower~ with a Classic 3.5HP B&S has a problem. I actually started it after bringing it out for its inaugural 2023 run, but 2nd time the pull cord snapped. Simply just worn out. This old thing has been a workhorse. I think I bought it when Mrs and I bought our first house ~1999 and it's been totally dead nuts reliable. I change the oil like once/decade, and that's about it. I remember draining the oil on it last time and maybe a few tablespoons came out. I am not against replacing it (maybe battery?) but I'm not against putting a couple bucks/effort into it as it has easily earned its keep. Hell, I think it's the original spark plug. 2 questions: Looks like the recoil assembly is riveted on. Are these replaceable? I think I've seen just cords available at Walmart... I presume cut to length and away you go? I see the cover with the serial # etc (bottom pic) looks like it simply unbolts, and the recoil assembly is attached to it? I've often thought of putting a hex drive on this and using my impact driver to start it. How insane of an idea is that? Not sure the best way to go about it. I don't have a welder, but know people who do.

|

|

|

|

I've repllaced a few pull cords in my time. I usually go to the local "lawn and garden" type place that sells and services this type of poo poo. Most frequent question they ask when I need a pull cord is "how much HP"? THe whole pull cord assy is probably replaceable, especially if its a B&S, but you can get away with just replacing the cord. Drill out the rivets and......... figure out how to reattach after. Probably just a few small nuts and bolts.

|

|

|

|

slidebite posted:I've often thought of putting a hex drive on this and using my impact driver to start it. How insane of an idea is that? Not sure the best way to go about it. Project Farm on YouTube does that ALL the time on YouTube for all of his engine product tests, although I think he uses a corded drill. Been there replacing a pull cord. The hardest part is getting the spring wound back correctly. It helps to count the number of turns of the pulley once you're inside.

|

|

|

|

I'll pop that cover off and see how it's attached. Rewinding springs can be a pain in the dick, if I can replace the whole top cover w/pull cord for something like $40 I'd probably do just that. I see tons of parts on Amazon, but not sure which is which without seeing the original. If it looks super easy with the pull cord, I might just try it. E: Just pulled the recoil assembly off. Looks really simple. Tying the knot properly will probably be the hardest part lol slidebite fucked around with this message at 19:57 on May 13, 2023 |

|

|

|

It was super easy. Got a generic cord and handle from a local hardware store for 7 bucks. Took all of maybe 10 minutes to put in.. The spring never unwound so I didn't have to fart around without it all. Hardest part was literally getting the knot for the handle in the right spot lol. Didn't even have to touch the rivets, whole assembly popped right off with the cover which was 3 bolts. slidebite fucked around with this message at 15:42 on May 14, 2023 |

|

|

|

Late to the party, but good job!slidebite posted:I think I bought it when Mrs and I bought our first house ~1999 You're probably right; on a B&S*, the first 2 digits of the Code are the last 2 digits of the year of production ("99"). *since 1965 Dagen H fucked around with this message at 18:22 on May 22, 2023 |

|

|

|

Last year I rebuilt this 1976 Jonsered 451 EV chain saw, carb rebuild, new ring for the piston (has only one ring). This year I am using it for some experimentation. The brush cutter I worked on earlier will also get a taste of this, E85 fuel with two stroke oil mix (3-4%, little richer than regular gas, just in case). And I gotta say a big success, saw ran really well all day and it never got as hot as with regular gasoline. Runs as clean as alkylate fuel but cooler.  Using what I got, I wanted a transparent glass container and this horrible vodka took 12 years to finish. Nice bottle though.

|

|

|

|

Picked this up today, from a trailer full of random poo poo outside a local scrap metal place: It's a 'Chipper/Shredder' with a Jiangdong JF200 (I'm guessing Honda GX200 clone?), and the labelling says that it will handle up to 2-3" diameter stuff in the branch chute I didn't think it ran, but it started first pull, and they threw in new tires because the ones that were on it were dry rotted. I got it home, swapped the wheels, threw some seafoam and fresh(er) gas in the tank - which had barely anything in it - and got it to start and run but it died out. Then the pull cord broke on me. The oil level is fine - it has 2 dip sticks, one on each side, and seems to be direct drive to the shredder wheel - there doesn't seem to be any kind of provision for a clutch to disengage. I found a manual online for the motor, and it seems to be original to the unit. I can't figure out make of the rest of it, but it seems to be a Troy Bilt clone and I'm guessing it came from Princess Auto (  version of Harbor Freight). version of Harbor Freight).Anyone have any idea where I might be able to find info on what (if anything) I need to grease before running it 'seriously'? Captain McAllister fucked around with this message at 03:56 on Jun 22, 2023 |

|

|

|

I'm trying to test whether the stator on my mower is working. The wire coming out from the engine only has one pin, so should I put the red end of my multimeter on that and the black end on a ground to test the AC voltage?

|

|

|

|

NotNut posted:I'm trying to test whether the stator on my mower is working. The wire coming out from the engine only has one pin, so should I put the red end of my multimeter on that and the black end on a ground to test the AC voltage? Nevermind, I figured it out. But now I'm wondering where to find my engine's model number. It's usually stamped into the metal somewhere right? Do I need to take the shroud off to see it?

|

|

|

|

NotNut posted:Nevermind, I figured it out. But now I'm wondering where to find my engine's model number. It's usually stamped into the metal somewhere right? Do I need to take the shroud off to see it? Is it a Briggs and Stratton? Mine was under the plastic on the front.

|

|

|

|

kid sinister posted:Is it a Briggs and Stratton? Mine was under the plastic on the front. Had to get a bunch of grease off to see it, but it was there, thanks.

|

|

|

|

We don't have a flathead engine thread (yet?) I'm going to try and turn over my flathead straight 8 sometime this week? I guess. It's basically 8 x 660cc flathead small engines welded together. Kinda. And it weighs 1000 lbs. It supposedly ran January 2023 and has been living under a tarp in socal since last March. Socal is usually pretty dry but they did just have a hundred year rain event last fall. There's a tiny bit of water in the oil but not bad. Both the starter and alternator look newer than 5 years which is a strong sign. And the fuel filter looks newish and the fuel not too gross or cruddy Thinking about putting a 50/50 mix of diesel/atf, I guess about 50ml, in each cylinder, just unscrew the spark plug and pour it into the cylinder. Each piston is about 80mm in diameter with a very long stroke. From there I'll wait... 4-5 days and try and turn it over? I already have a set of nearly-actually 2" sockets arriving tomorrow. I suspect it'll turn over without the penetrating mix but I have some time and I'm in no hurry. I can rotate the front crank wheel with my hands a ~1/128 which is probably (hopefully) more than bearing play If I can get it to turn over I'll jack it up and weld together a stand in place (it's currently strapped to a HF furniture dolly) and then... Try to start it? Is it worth getting a $7 fluid transfer thing? https://www.harborfreight.com/multi-use-transfer-pump-63144.html Not sure if this even has an oil filter and the oil plug is in an inconvenient location (and shallow and like, nearly 2" in diameter?) and I'd like to get the watery oil out before I pump it through the whole engine.

|

|

|

|

Hadlock posted:Thinking about putting a 50/50 mix of diesel/atf, I guess about 50ml, in each cylinder, just unscrew the spark plug and pour it into the cylinder. Each piston is about 80mm in diameter with a very long stroke. From there I'll wait... 4-5 days and try and turn it over? I already have a set of nearly-actually 2" sockets arriving tomorrow. I suspect it'll turn over without the penetrating mix but I have some time and I'm in no hurry. I can rotate the front crank wheel with my hands a ~1/128 which is probably (hopefully) more than bearing play Why are you doing this? Is it seized? I mean, you can do this but it sounds totally unnecessary. Of course if you know an engine is not going to be fired up for a year or two you can take some precautions when you shut it down for the final time and spray/fog something into the cylinders, but if you don't it's not necessarily the end of the world and automatically seize up. slidebite fucked around with this message at 21:24 on Feb 19, 2024 |

|

|

|

Hadlock posted:If I can get it to turn over I'll jack it up and weld together a stand in place (it's currently strapped to a HF furniture dolly) and then... Try to start it? Is it worth getting a $7 fluid transfer thing? Why not, like, actual penetrating oil? Also, if you have to ask "is ruining this engine not spending $7" you already know the answer.

|

|

|

|

I don't know if it's siezed; I'd rather not break a ring as there's a single supplier of parts for this engine and they charge accordingly Project farm did a battery of antisieze tests and the ATF/diesel mix came out way ahead of commercial blends, also seems to be standard practice Wasn't sure if the extractor was best practice or not. Actually I think in this case it is; the drain plug for this engine sits a good half inch above the bottom of the oil pan, facing the rear, not down, so probably doesn't do a great job compared to an extractor that can reach to the bottom of the pan I don't know poo poo about how to deal with an engine in an unknown state so just going down the preflight checklist

|

|

|

|

Preflight checklist of unknown state is not include dumping stuff down the bores. Squirting a bit of oil in the cylinders isn't totally insane, but filling it with a home brew of penetrating oil in an engine that isn't seized is not required and won't accomplish anything of value. See if you can spin it by hand. Remove the plugs first to assist. If it ran last year, unless it was used as an anchor sitting at the bottom of a lake it's unlikely its seized unless you have reason to think otherwise. If you can't turn it by hand, then instead of doing the liquid fix it, start tearing it down if you're super concerned about spare parts.

|

|

|

|

Quickest & cheapest thing to do is run a cheap borescope down the spark-plug holes & assess the cylinders visually. If it ran last year, and you can turn it by hand at the pulley, then itís fine. The risk to the rings arises when itís really stuck fast. For peace of mind, spray some penetrating oil in each cylinder and hand-crank it through a couple revolutions. If you squirt motor oil into the cylinders, use something lightweight and put less than half a shotglass in each one. Let it sit overnight & then turn it through a few revolutions. Pontiac loves to mount the drain plugs like that. Occasionally, Iíd pour a quart in the top while it was draining, to push out more old oil. Usually donít bother, though. In your case, try to mount it on a stand so it is tilted towards the drain a bit. For what itís worth, Iíve been running a pontiac 389 like that for 24-years. It doesnít leave enough old oil behind to be a problem PainterofCrap fucked around with this message at 06:01 on Feb 20, 2024 |

|

|

|

|

| # ? Apr 20, 2024 04:34 |

|

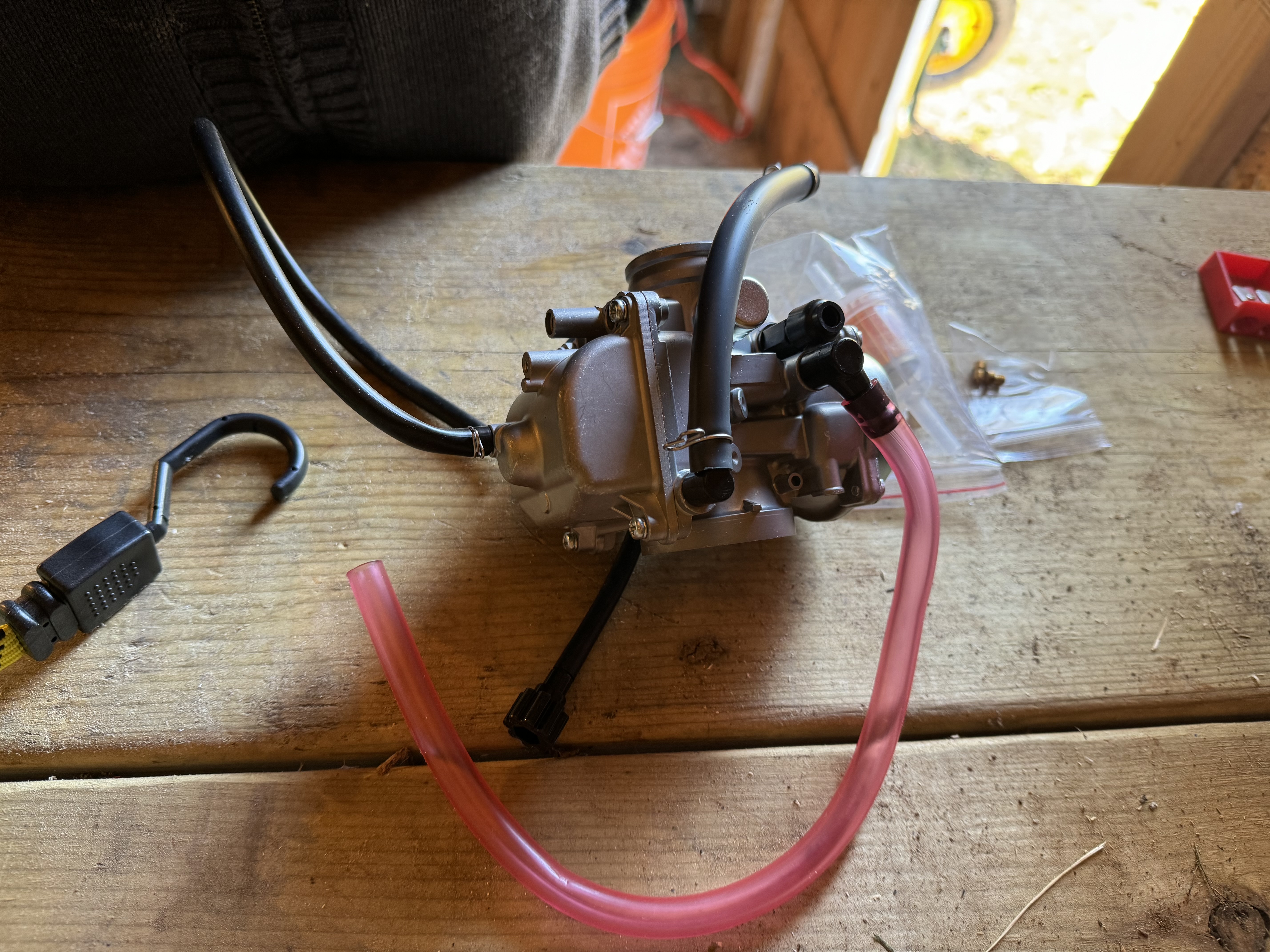

Crossposting from the fix it fast thread: I have an ATV (Linhai 400) that needs a new carburetor. It may need other things but I also changed the battery and air filter. Iíve taken off the old carburetor, dismantled and cleaned it and put it back on. The atv starts, but floods and doesnít run well. Fuel also dripped from somewhere. The exhaust also became red hot quite quickly. I bought a new carburetor for it.   Hereís a video of me looking at the carburetor as it sits on the ATV. https://files.catbox.moe/ufmp5r.mov I have labeled the tubes for discussion.    Iím confused because there are more hoses on the new carburetor than I have spots for, so I donít know where to put them. Edit: as in, the existing carburetor has all the same ports but insufficient hoses. I know the rough anatomy of an ATV after lots of reading online. I donít know what each part of this carburetor is supposed to lead to. I also donít know if the thing was ever installed correctly or if I missed things, so itís very possible the labeled tubes are going to the wrong places currently. Can someone tell me where I should plug in each hose? tuyop fucked around with this message at 23:12 on Apr 2, 2024 |

|

|

|