|

Dumb question... Drilling hammer vs engineer hammer vs ball peen. I need a couple new hammers, and it would be used for the typical bullshit. U joints, ball joints, beating things, you know typical car repairs. Any suggestions? I already have assorted rubber mallets and a couple of claw hammers. I never realized that I don't have a good BFH BrokenKnucklez fucked around with this message at 04:28 on Oct 22, 2014 |

|

|

|

|

| # ? Apr 25, 2024 10:17 |

|

Timmy Cruise posted:Dassault also has draftsight: http://www.3ds.com/products-services/draftsight/download-draftsight/ Was going to mention this as well. Sketchup is alright as long as you don't try to do too much with it. Want to mock up a arcade cabinet or subwoofer enclosure? Sketchup is free and relatively simple to use. Using it for any more than that is an exercise in frustration.

|

|

|

|

BrokenKnucklez posted:Dumb question... What is supposed to be the difference between engineer and drilling? Most times the one I like is called "engineer's drilling hammer". It's a shorty sledgehammer, square-ish flat faces on both ends. I prefer a solid metal one over one with a wooden handle because hey, one less thing to break (and I never ever want to watch a 4-pound sledge head cartwheel away through the air).

|

|

|

|

BrokenKnucklez posted:Dumb question... I wouldn't go after a stubborn ball-joint, etc. with a metal BFH, as that tends to be more of a dead-blow mallet job. So for more hammers, I'd go for a set of ball peens that you can also use for sheet metal shaping, etc.

|

|

|

|

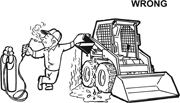

Head design and handle length for the differences between engineer and drilling hammers. Engineer hammers resemble small sledges due to the head design and the longer handle.

|

|

|

|

Hammer purchases are not something for which the word "or" is intended.

|

|

|

|

I have a need for a torque wrench. My neighbor broke his. What the hell am I looking for in a torque wrench? I'm kinda interested in one of those expensive electronic ones. Are those digital socket wrench torque adapters worth a dang? That would be kinda cool but seems bulky.

|

|

|

|

I've only ever used the $20 torque wrench from Harbor Freight and haven't had any major issues with it. I don't think I'd rebuild the head of an exotic race car with one, but for putting on tires and suspension parts it's probably just fine.

|

|

|

|

InitialDave posted:Hammer purchases are not something for which the word "or" is intended. Truth. Why even ask? Tamir Lenk posted:I wouldn't go after a stubborn ball-joint, etc. with a metal BFH, as that tends to be more of a dead-blow mallet job. So for more hammers, I'd go for a set of ball peens that you can also use for sheet metal shaping, etc. One good whack with a metal hammer is usually all it takes to break poo poo free. Besides all my poo poo that I do is take apart and replace. I have yet to reuse suspension parts. (Because if that poo poo is apart it's getting replaced)

|

|

|

|

Don't forget that castings often don't like being hit with metal hammers.

|

|

|

|

mod sassinator posted:I've only ever used the $20 torque wrench from Harbor Freight and haven't had any major issues with it. I don't think I'd rebuild the head of an exotic race car with one, but for putting on tires and suspension parts it's probably just fine. I had a buddy of mine test his on a transducer at work. It was a lot more accurate than we thought it would be. With in less than 5% IIRC.

|

|

|

|

Wasabi the J posted:I have a need for a torque wrench. My neighbor broke his. I love this sentence so much. HF Torque Wrench for me, seemed to be the same quality as the slightly more expensive one I bought at Ace. Easy to use, reliable and simple. Remember to turn it down to zero to release the load on the mechanism to keep it as accurate as possible. I had mine for about a year and I'm thinking of replacing it for three reasons: I haven't heard that before, they cost $10, and I'd like to test that statement out. If that statement holds false, I'll give the old one to somebody as a gift.

|

|

|

|

StormDrain posted:

No. That's not how metal works. In fact, turning it down to zero is slightly detrimental to the longevity of a torque wrench.

|

|

|

|

BrokenKnucklez posted:Dumb question... Get a 3-4lb hammer with a flat face and a chisel face and for really stubborn jobs, an 8lb full size sledge, then whack half the handle off with a chopsaw. Ball pein hammers are (IMO) mostly for metal shaping - the rounded end moves metal around and stretches it better than a flat face will. The chisel face of an engineers/drilling/blacksmiths hammer (whatever you want to call it, I don't care) is great for hitting things with a little more precision than the flat face, but just as much force. The 8 pounder is great when a goddamn balljoint or tie rod taper just plain won't move. I popped a 200k+ mile, 20 year old rustbelt one ton truck's tie rod end taper out of its steering knuckle with a single swing when I used mine for the first time and was immediately glad I bought it. If you don't have a deadblow, get one of those too. Rubber mallet full of lead shot, basically. All the violence that comes with weight, none of the surface marring. I use mine to get differential carriers into housings when I don't have a case spreader available (i.e. every time.) e: I am also a bad person and make use of the 8 pounder when an arbor press won't get the job done. Example - leaf spring bushings. kastein fucked around with this message at 21:27 on Oct 22, 2014 |

|

|

|

Is a rubber mallet or a dead blow hammer for knocking things loose (like a stuck brake rotor)?

|

|

|

|

Uthor posted:Is a rubber mallet or a dead blow hammer for knocking things loose (like a stuck brake rotor)? For knocking a brake rotor loose, probably won't matter between the two.

|

|

|

|

Safety Dance posted:No. That's not how metal works. In fact, turning it down to zero is slightly detrimental to the longevity of a torque wrench. This gets said a lot, and makes sense, but I read an article in FourWheeler that had empirical data showing a torque wrench losing accuracy over time when stored at 70 ft lbs (I just wish they would have had a control stored at a lower setting to be more conclusive). The article: http://www.fourwheeler.com/how-to/129-1307-torquing-testing-torque-wrenches/ (confirms that HF wrench is plenty accurate) The important part:  ...I agree not to put it at zero though; put it near, but not at, the lowest setting its designed for.

|

|

|

|

metallicaeg posted:For knocking a brake rotor loose, probably won't matter between the two. I just feel like a lot of energy goes into making the rubber mallet bounce back, but am having a hard time picturing where the energy goes in a dead blow. For what it's worth, a mallet didn't help me last time, but good old mechanical advantage did (I posted a video earlier in this thread using a bolt and a nut).

|

|

|

|

Uthor posted:I just feel like a lot of energy goes into making the rubber mallet bounce back, but am having a hard time picturing where the energy goes in a dead blow. Someone correct me if I'm wrong, but I think I remember that an elastic collision has twice the energy as an inelastic one. Since there are equal and opposite forces, the amount of energy that gets turned into the hammer bouncing back also is imparted into the object you're hitting.

|

|

|

|

If I'm taking a brake disc off, it's probably junk and getting replaced, so I just hit it with the BFH.

|

|

|

|

Safety Dance posted:No. That's not how metal works. In fact, turning it down to zero is slightly detrimental to the longevity of a torque wrench. How so? I'd expect that the forces and temperature not enough to make a difference, but I don't understand how being at zero would be detrimental. I thought the spring would lose it's strength due to creep, and since it's not very long that could cause some real changes in the torque reported. From 0-250 is less than an inch of compression. It's been nearly 10 years since I was in my materials science course, but I still understand the stress/strain diagram.

|

|

|

|

StormDrain posted:How so? I'd expect that the forces and temperature not enough to make a difference, but I don't understand how being at zero would be detrimental. I thought the spring would lose it's strength due to creep, and since it's not very long that could cause some real changes in the torque reported. From 0-250 is less than an inch of compression. It's been nearly 10 years since I was in my materials science course, but I still understand the stress/strain diagram. Something about the ball that makes the wrench click falling out or unseating or something.

|

|

|

|

InitialDave posted:If I'm taking a brake disc off, it's probably junk and getting replaced, so I just hit it with the BFH. I use my rubber mallet on wheels that are stuck to the rotor. The rule I have kinda followed is "if its metal and I want to save it or protect it, rubber mallet" How true that is I don't know but its worked so far.

|

|

|

|

StormDrain posted:How so? I'd expect that the forces and temperature not enough to make a difference, but I don't understand how being at zero would be detrimental. I thought the spring would lose it's strength due to creep, and since it's not very long that could cause some real changes in the torque reported. From 0-250 is less than an inch of compression. It's been nearly 10 years since I was in my materials science course, but I still understand the stress/strain diagram. There's creep, which shows up when you keep the torque wrench at one torque forever. It show up most at temperatures way higher than you'll see in your garage. Then there's fatigue, which shows up when you keep moving the spring over and over again. The effect of fatigue is much greater than the effect of creep. Cat Hatter posted:This gets said a lot, and makes sense, but I read an article in FourWheeler that had empirical data showing a torque wrench losing accuracy over time when stored at 70 ft lbs (I just wish they would have had a control stored at a lower setting to be more conclusive). Finally, there's ridiculous n=3 studies that don't demonstrate anything in a statistically meaningful manner.

|

|

|

|

So then why do manufacturers recommend you set it to lowest torque before storing? I have a Tekton Torque wrench, so one step above HF, but that's what it says in the instruction manual.

|

|

|

|

What's the best and most affordable scissor lift on the market currently?

|

|

|

|

Safety Dance posted:There's creep, which shows up when you keep the torque wrench at one torque forever. It show up most at temperatures way higher than you'll see in your garage. Don't take this the wrong way, but I trust the instructions of the precision measurement lab that calibrates all our stuff, from high spec torque wrenches to $100K pieces of test equipment over non-cited words on the internet. Their instructions are as follows: before using, adjust the wrench to max torque, click/break 3 times (we have a bench bar for this), set to needed torque, torque fastener, and return it to zero before storage. Most of our in/lbs stuff has a +/- 3-5 tolerance spec, and our foot/lbs has a +/- ~2-5 spec. We rarely lose a torque wrench to non-calibrated status.

|

|

|

|

Wasabi the J posted:I have a need for a torque wrench. My neighbor broke his. I loves me the electrohailsatanwhatever snapons we have at work, but they're priced something ridiculous around $4k, if you really want to drop coin. A handful of buddies seem to love the eastwood electronic torque wrench, saying it's the same as the craftsman for half the price, but ymmv. The digital adapters aren't worth their weight in cheap chinese internals, unless you're looking for a step up above redneck calibration using weight plates. HF torque wrenches aren't bad, aren't good, but for $9 on sale with a lifetime warranty, they're alright for keeping around. I tend to break teeth off of the ratcheting gear at least twice a year, and I only use them for lug nuts and suspension bits at home. McSpatula fucked around with this message at 04:34 on Oct 23, 2014 |

|

|

|

I've recently bought a couple of norbar torque wrenches and am extremely pleased with them.

|

|

|

|

Safety Dance posted:Finally, there's ridiculous n=3 studies that don't demonstrate anything in a statistically meaningful manner. Three data points is better than no data points, especially since the whole demonstration was prompted by a guy who tests and calibrates torque wrenches for a living that wanted to show that the guys who design torque wrenches know what they're talking about.

|

|

|

|

So you're saying he began his experiment with a desired outcome?

|

|

|

|

Everything about that graph bothers me. Why is it a line graph? Why isn't time on the x axis? Why are the axis unlabeled? It should be one of those graphs that has error bars around the data points.

|

|

|

|

It's a Harbor Freight Torque wrench, if you keep if long enough for fatigue/creep/whateverthefuck to set in, you are doing it wrong. You use it for 6 months, then buy a new one. This is how HF stays in business.

|

|

|

|

$22 in shop your way points expire today. What do I buy?

|

|

|

|

kmcormick9 posted:$22 in shop your way points expire today. What do I buy?

|

|

|

|

I really should quit my day job and just be a traveling salesman for those things because goddamn they rock. Put it this way - I usually use mine instead of a flare nut/line wrench these days when I need to get a flare loose without stripping it. They're that good.

|

|

|

|

Seriously, they are great. Someone finally invented an adjustable that doesn't suck.

|

|

|

|

kastein posted:I really should quit my day job and just be a traveling salesman for those things because goddamn they rock. Great for chromed nuts to avoid marring the surface.

|

|

|

|

I wish they made a slightly smaller version of it too. Like maybe 6-8" so you can have a small and big one for any size nut.

|

|

|

|

|

| # ? Apr 25, 2024 10:17 |

|

So I'm convinced that I need to go buy some more hammers. I've already got a 3lb drilling hammer and a small dead-blow with replaceable heads (one plastic and one rubber). I think I need a bigger BFH and a bigger dead-blow. HF here I come.

|

|

|