|

MrMoo posted:Why such a price for the gear on the left? Couldn't you import it cheaper? Unsurprisingly there are kick starters for more affordable metal 3d printers, the price on the left is for the battery that is above, just resuing the battery's product case to hold the little poo poo, the gear on the left was $3.49

|

|

|

|

|

| # ? Apr 29, 2024 18:42 |

|

MrMoo posted:Why such a price for the gear on the left? Couldn't you import it cheaper? thats the battery price you palooka

|

|

|

|

any desktop 3D printer should have no problem printing gears with a module of 1mm. 0.7 to 0.5 if you've got good calibration. you need a dense, wear-resistant material obviously; PLA isn't going to pull that off. ABS may be okay, nylon will be good too if your machine can do it. there's a special high lubricity filament that's generally called "tribo-filament" that's ideal for gears and other moving mechanical parts -- check it out. or if you're super hardcore, it is possible to print directly in polyacetal the tribo-filament gears might be okay in an RC car transmission as long as the torque isn't too ridiculous.

|

|

|

|

Sagebrush posted:as long as the torque isn't too ridiculous. it is

|

|

|

|

wrt printed gears, they are used all the time on reprap extruders. you can see examples here http://www.thingiverse.com/thing:18379/#made you would probably need thicker gears and chunkier teeth to spread the load over a wider contact area. also your minimum feature size is limited by the nozzle diameter, meaning the tips and valleys of the gears would be rounded to a circle about .4mm dia for typical nozzle. you can go to smaller nozzle sizes but not much beyond .3mm or the nozzle pressures are too much to deal with aiui but i've only ever used .4 most people do them in ABS for its heat tolerance, but that material grinds itself into a powder after extended use. i've been printing them in PETG filament lately, seems to have better wear resistance, no noticeable powdering or wear of any kind.

|

|

|

|

3d printing is neat and cute it is not appropriate for multi thousand rpm RC car drivetrains with enough instantaneous power delivery behind them to drill or weld sheet metal

|

|

|

|

Buy metal gears you dildos. 3D print things like custom motor mounts for your completely custom chassis

|

|

|

|

Jonny 290 posted:3d printing is neat and cute a properly printed gear is better than 80% as strong as an injection-molded one, and there was clearly a plastic molded gear on the previous page. my old competitive rc cars used a couple of polymer gears specifically as wear points to prevent shock damage to the rest of the drivetrain obviously if you make it out of chinese floor sweepings PLA on a miscalibrated reprap the gear will be lovely. use the right filament and proper settings on a good machine and you might be surprised. i have a printed ABS gear running in an engine lathe gearbox, replacing a fiber spur that dried out and blew up, and it's perfectly fine

|

|

|

|

BiohazrD posted:Buy metal gears you dildos. 3D print things like custom motor mounts for your completely custom chassis this is what i'm sayin'. You wanna gently caress around with shock mounts and gopro anchors for your car? go hog fuckin' wild with your filament bukkake. rotating/oscillating parts? negative ghost rider, the pattern is full of .001" or better CNC'd parts. if any of you think sniep is the kind of fellow to dump a grand into a 3d printybox to get a gear that's 80% as strong as he can buy in the dollar bin at the RC store, you dont know sniep

|

|

|

|

it's more me assuming that everyone has a 3D printer these days, which i have to keep reminding myself is not the case like, i own two and run six more at work and we have all the materials and calibration dialed in and everything. so now half the time i need a part it's just like eh, 3d print one, i can't be bothered driving to the store. visited my dad over the summer and showed him a copper-filled printed part that i was screwing around with and he had a couple friends over and they were like "i have never seen or held a 3D printed object before" and I was like, oh, right, this is still uncommon stuff

|

|

|

|

is there a hobbyist angle to use 3d printing for lost material casting yet ? because _that_ is what i'm interested as poo poo in i dont want to spend a billion dollars for a printer that can print my engine block model. i want to spend a grand for a printer that prints a foam negative that i can sand pack and cast aluminum into.

|

|

|

|

yeah, you can buy burnout-rated filaments for any FDM printer now, and the same in resins for SLA machines if you want to spemd a little more for smaller build but higher precision (eg jewelry casting). here you go https://www.matterhackers.com/store/3d-printer-filament/moldlay-filament-1.75mm sand casting is technically possible but given the scale and properties i'd probably start with investment casting instead

|

|

|

|

fuuuuuck. yeah see thats what im talking about nice

|

|

|

|

supposedly lost PLA casting works fine and the material vaporizes away completely

|

|

|

|

God drat 65 bucks for .75 kg

|

|

|

|

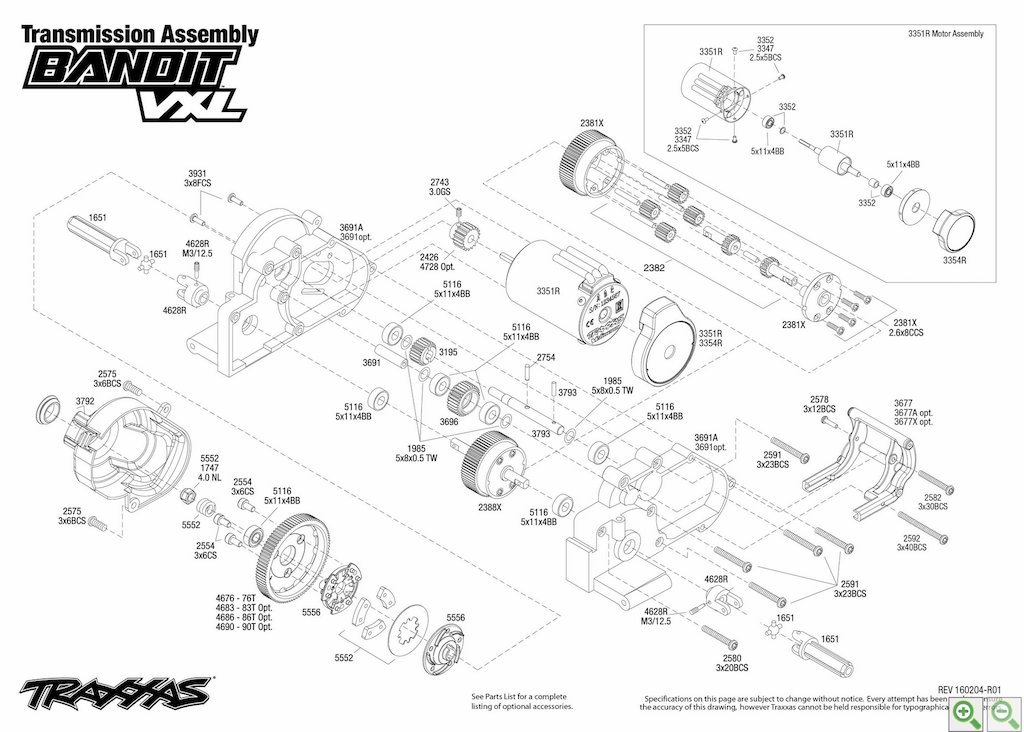

btw this is the assmebly im speaking of: and that fits in the palm of your hand

|

|

|

|

But yeah give me something that I can make an aluminum model out of I was gonna get a shapeoko but apparently they really can't do full on cnc metal milling

|

|

|

|

cnc machining metal is a way more difficult process than a lot of people think. just ask rotor. it's much more about being a machinist than it is about being a computermans. ask yourself what you're trying to make and if metal is really necessary. engineering thermoplastics are amazing things, and you can even print fiber-reinforced polymers these days. there's a great future in plastics

|

|

|

|

I have absolutely 0 things that need to be milled metal. I want one because it's cool as gently caress and I wanna learn about it Maybe I should enroll in the local cc and take a metal working class at night for shits and giggles

|

|

|

|

Jonny 290 posted:3d printing is neat and cute If it works for NASA and their rockets I think its going to be fine for an RC car.

|

|

|

|

MrMoo posted:If it works for NASA and their rockets I think its going to be fine for an RC car. if you're handing out nasa grade 3d printers that have that level of precision i'm more than willing to give it a shot

|

|

|

|

Sagebrush posted:cnc machining metal is a way more difficult process than a lot of people think. just ask rotor. it's much more about being a machinist than it is about being a computermans. ask yourself what you're trying to make and if metal is really necessary. engineering thermoplastics are amazing things, and you can even print fiber-reinforced polymers these days. there's a great future in plastics even then i question the rigidity of rotor's taig mini mill for cutting steel, but the huge fuckoff cnc i got is still comparatively small potatoes. different tools for different uses. i have the g0704 mill for aluminum and steel parts, and then i have a shapeoko to cut flats like plastic and fiberglass because you need high spindle rpm with carbide bits to get through that stuff.

|

|

|

|

BiohazrD posted:Build your own rc car! i had this thing and it was loving awesome for like 7 minutes at a time

|

|

|

|

look cosely. there is no left/right controls. the left throttle is for the 2 left wheels and right is for the 2 right wheels. mega ftw.

|

|

|

|

i have a programmable radio so you can set up the sticks to do whatever you want. for cars with L/R motor drivetrains, i have three different presets -- one "tank drive", where you control the motors individually, one "arcade mode", where you use the right stick for all movement, and one "twin stick" where the left one controls throttle and the right controls steering. and the best part is thanks to  these radios cost like 50 dollars. go pick up a turnigy 9x these radios cost like 50 dollars. go pick up a turnigy 9xCrazyLittle posted:even then i question the rigidity of rotor's taig mini mill for cutting steel, but the huge fuckoff cnc i got is still comparatively small potatoes. just get a spindle speeder for the grizzly also, try single flute HSS tools for soft materials like plastic. hss forms a sharper edge than carbide and tool sharpness + maximum chip clearing is the most important thing to avoid melting. fiberglass you should probably stick with carbide cause it's abrasive

|

|

|

|

|

|

|

|

FLUX SPATTER WARNING

|

|

|

|

lol

|

|

|

|

tyvm, i'm saving this for my class

|

|

|

|

dude in the middle has a crazy tiny head

|

|

|

|

how to do a dork pbx at home by 290 in over generalized steps but still showing how non crazy it is now: -raspberry pi 2 -8gb or better microsd -some sort of sip phone. right now I have a sip cordless (grandstream 710) that owns, a couple FXS adapters that speak SIP on one side and POTS on the other for old school phones, and i also use X-lite on my mac which is a totally fine sip client. You can gently caress with cisco 7960's and stuff too but that's advanced tier -some sort of access trunk, usually via SIP. Again you can gently caress with google voice for free but i recommend http://didlogic.com if you have a couple dollars to throw at it. my lines are 99 cents a month plus $0.0056 a minute in or out, totally reasonable. its prepay style, throw 10 or 20 bucks on and you have enough credit to play with 2-3 lines for several months. if you just want multiple calls you have up to 24 channels at once, you dont need extra numbers. i used this image and guide. http://www.raspberry-asterisk.org/ SIP = internet phone protocol extension = a phone in your house trunk = connection to the real phone network (usually using SIP) dialplan = how asterisk decides where to poo poo out a call ivr = voice menus with fancy functions download the latest image, put it on a card and boot the pi on your network. find the IP and browse to http://192.168.420.69 or whatever and log in. change passwords add SIP extensions for your phones. at least one for x-lite or whatever softphone you're testing. note the extension and password. beyond that you dont need to tweak settings. then set up your trunk. i used didlogic's inhouse guide here. follow to the letter. some things on the newest freepbx gui are on tabs and poo poo but all the fields are there. Point the trunk to your newly created SIP extension above. (assuming you have this behind a conventional nat router:) Then go up to Settings and select SIP settings, on the general SIP tab you need to enter your public IP (it doesnt change that much, deal with it) and local network, and on the chan_sip tab you need to enable NAT and punch that IP in again now log into your config interface for whatever SIP toy you have, be it grandstream or a FXS or whatever and configure it to connect to the asterisk box. all you really need is the IP, extension and password ("secret" sometimes). after you reload asterisk and get these up you should be able to see both your SIP trunk and your phones if you ssh in, then run 'asterisk -r' and then do a 'show sip peers': code:im moderately swift with asterisk now so if you wanna f with this and have questions i will crawl through the mud with you Jonny 290 fucked around with this message at 08:37 on Mar 8, 2016 |

|

|

|

make sure to wear your gunnars if you have 'em

|

|

|

|

Jonny 290 posted:-some sort of sip phone. right now I have a sip cordless (grandstream 710) that owns, Does that phone support multiple lines? Like can you tell which line a number is coming in, a different ring tone or something?

|

|

|

|

this one's just a single line by itself (like if you just strapped it to a sip trunk, which is how i had it set up before). you can set up a phonebook and pick one of like 8 ringtones for each entry, combine that with asterisk's ability to rewrite CID and you could hack something together. as far as standards-compliant distinctive ring tho, it doesnt have it

|

|

|

|

Found that Yealink has support for multiple lines but has not great reviews and the phone is 3 years old already, it always seems that the cordless phone market is very much stagnant (the Grandstream GS-DP715 is 2012).

|

|

|

|

yeah it doesnt really move fast. my next hurdle is to navigate the cisco fuckpile which involves tftp and all that cool garbage

|

|

|

|

Jonny 290 posted:yeah it doesnt really move fast. my next hurdle is to navigate the cisco fuckpile which involves tftp and all that cool garbage noooo jonny turn away

|

|

|

|

dude im ex ccna, i've already touched the poop and re-sterilized. i know to use protection this time

|

|

|

|

MrMoo posted:Found that Yealink has support for multiple lines but has not great reviews and the phone is 3 years old already, it always seems that the cordless phone market is very much stagnant (the Grandstream GS-DP715 is 2012). these are actually some of the best sip cordless phones on the market that i've seen. the aastra ones are prettier but who the gently caress uses aastra. panasonic dect poo poo was always good but who knows if the sip portion is up to par. but cisco? fffffffffffffffffffffffffffffffffffffffffffff

|

|

|

|

|

| # ? Apr 29, 2024 18:42 |

|

Jonny 290 posted:dude im ex ccna, i've already touched the poop and re-sterilized. i know to use protection this time ex? i thought you were still doing networky poo poo

|

|

|