|

sharkytm posted:Heat, a good punch that's the correct size, and a big dead-blow hammer are your best bets. You'd have to really cook it to get enough heat to damage anything underneath, and you could wrap a wet rag under the head if you're worried. That's certainly the wrong spot for a steel roll pin. 8mm diameter by 40mm long, so a standard size, but I'm in Sweden and I highly doubt McMaster will ship one here by Friday

|

|

|

|

|

| # ? Apr 24, 2024 15:37 |

|

TheFluff posted:8mm diameter by 40mm long, so a standard size, but I'm in Sweden and I highly doubt McMaster will ship one here by Friday Well, you're going to need something to go in there after you get it out, because that one is chooched

|

|

|

|

meltie posted:Well, you're going to need something to go in there after you get it out, because that one is chooched Definitely, and I have a lead on where to get one, just need to take a bicycle ride tomorrow or on Wednesday

|

|

|

|

TheFluff posted:Definitely, and I have a lead on where to get one, just need to take a bicycle ride tomorrow or on Wednesday I mean, if you paid enough, they'd have it in Sweden in 48 hours. I once had to ship a package from Massachusetts to Nuuk Greenland in 48 hours, and it is indeed possible. It's not cheap, but possible.

|

|

|

|

sharkytm posted:I mean, if you paid enough, they'd have it in Sweden in 48 hours. I did a couple courier trips when I was young and unattached and unemployed. If youíre willing to pay, you can do a lot better than 48 hours.

|

|

|

|

Speaking of losing tools overboard, I had a dream the other night that the tide at our river house was so low that the bottom was exposed in our boathouse. I found the bow saw I dropped this past summer, as well as a ton of tools previous owners had lost, in amazingly good shape.

|

|

|

|

Iíd be worried about whatís causing the gelcoat to crack that badly. Looks like it lines up perfectly with the fasteners. Are they through-bolts or tapping screws? Whatís on the inside for a backing plate? Is there play in the upper or lower bearings? Is the rudder post still attached to the hull at both ends? Is the rudder stock still straight? These are all questions where I have found the answer was Ďitís hosedí and the downsides to losing your rudder under way are rather large. It is worth removing and assessing the whole system, especially if you canít document the last time it was done. Iím not sure what sort of rudder you have, if itís a fin or skeg or what, but regardless you should check it out thoroughly. The tiller head looks like chromed bronze to me. That looks like a solid stainless rudder stock, maybe 1-1/2Ē diameter? I canít tell if the wider part under the head is a bushing or if there is a step in the stock and itís actually much thicker under the head? Is rudder post continuous or is there a gap for an autopilot? A hex on the person that put a mild steel spring pin in there.

|

|

|

|

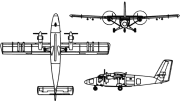

Big Taint posted:Iíd be worried about whatís causing the gelcoat to crack that badly. Big Taint posted:Looks like it lines up perfectly with the fasteners. Are they through-bolts or tapping screws? Whatís on the inside for a backing plate? Is there play in the upper or lower bearings? Is the rudder post still attached to the hull at both ends? Is the rudder stock still straight?  I'm not sure what you mean when you ask if there's play in the bearings or if the rudder post is still attached. I think the rudder post (axis?) is straight but I have no way of verifying. Big Taint posted:These are all questions where I have found the answer was Ďitís hosedí and the downsides to losing your rudder under way are rather large. It is worth removing and assessing the whole system, especially if you canít document the last time it was done. Iím not sure what sort of rudder you have, if itís a fin or skeg or what, but regardless you should check it out thoroughly. e: No it's not a skeg rudder at all, the correct term for what I have seems to be a "semi-balanced spade rudder". It was only a skeg rudder on older models. Big Taint posted:The tiller head looks like chromed bronze to me. That looks like a solid stainless rudder stock, maybe 1-1/2Ē diameter? I canít tell if the wider part under the head is a bushing or if there is a step in the stock and itís actually much thicker under the head? Is rudder post continuous or is there a gap for an autopilot? On my boat (which is very late production), I'm 99% sure that the post I have is a 50mm (OD) stainless steel pipe (ID 39mm, so 5.5mm wall thickness) with a solid 30mm-ish extension somewhere above the upper bushing (which is not directly under deck, it's maybe a decimeter down - see blueprint above), and that's what the tiller is mounted on. I believe what's keeping the rudder up is a... lug? flange? - English is hard - above the upper bushing, but I don't know how rudders work so idk. It's not clear from the blueprints. What is clear though is that it's definitely not hanging off of the tiller head because the tiller head is not in direct contact with the plate below. The rudder post is continous below deck, there's no autopilot. What I'm really concerned about is that these cracks have probably leaked for a long time and there's probably a lot of wood support underneath that's quite likely to have rotted away. e: I believe this is my rudder:

TheFluff fucked around with this message at 15:54 on Apr 30, 2020 |

|

|

|

TheFluff posted:I'm somewhat concerned as well but I think it's mainly down to no maintenance for a long time. There's only been one previous owner for the last 40 years and while he took good care of many things, he does not seem to have been interested in gelcoat repairs. He explicitly pointed out some very, very old cracks to me at some point with a story of how they got there. Gelcoat cracks when it flexes. However, Iíll bet that they didnít drill big enough pilot holes and/or didnít countersink them. Always countersink holes in gelcoat, kids, or it will crack like that. Plus it makes a nice pocket for extra sealant. TheFluff posted:The fasteners are tapping screws. I'm not sure what the backplate is (if there even is any). Here's the best blueprint I have that shows the entire assembly: Iím not sure if your deck is cored or not, but tapping screws into cored decks (and with cracks like that) are not good. Since that part is raised they may have kept the glass solid there, hopefully. If you can get at the bottom of it Iíd probably through-bolt if I could, preferably with a backing plate of some kind, not just fender washers like 99% of people do. Iím also not sure if that ring is part of the upper bearing or just a cosmetic cover? It looks like itís the flange for the shell that Teflon bushing fits into? In which was itís under load. TheFluff posted:I'm not sure what you mean when you ask if there's play in the bearings or if the rudder post is still attached. I think the rudder post (axis?) is straight but I have no way of verifying. Get under the boat and try to waggle the tip of the rudder around. It shouldnít move much. Ideally not at all. Things that can cause movement are worn bearings/bushings or separation of rudder post from hull. The post is the tube from deck to hull that the rudder stock passes through. Usually itís glassed to the hull at the top and bottom. That joint can fail. That is bad. Much more likely is the Teflon bushings are worn, and if the bottom is worn more that the top, itís a big lever putting force on that top bearing and making those cracks get worse over time. I donít see any cracks around the raised part of the deck where itís mounted which is good. TheFluff posted:I could ask the previous owner if it's ever been disassembled but I sort of doubt it. Iím curious to know whatís holding the rudder in then, probably wonít be able to tell until the tiller head is off. Itís going to install up from the bottom so there canít be any wider flange on top of the stock holding it. Often the tiller head is in fact the thing that holds it up; when youíre in the water the rudder is (normally) buoyant so itís not dragging on the bearing much vertically. On roller bearings with an inner race sometimes that is pinned to the stock to hold it up. Make sure thereís something supporting the rudder before you remove that spring pin, itís not impossible that itís keeping the rudder in the boat.

|

|

|

|

Got it out Didn't need any heat in the end, just leaving the 5-56 to do its job for a few days loosened it up enough.  The metal ring that's screwed to the deck has a flange on it that continues below deck several centimeters into a hose that covers the top of the rudder post and the upper bushing. I removed some wood paneling that was hiding the rudder post below deck and here's what it looks like:  The hose seems glued onto the flange (in addition to the hose clamps) and we couldn't get it loose - at least not without using more violence than we were prepared for so close to splashing. There's some rust around the bottom of the post where it goes through the hull, which is concerning, but there's nothing we can do about that now. I know of at least one other owner of a boat of this type that has done fiberglass repairs in this area because it was starting to crack after 40 years. I might have to do the same this fall. For now though, ground out the cracks with a dremel:  And patched them up with new gelcoat. This is a hack job and it will almost certainly crack again sooner rather than later but my goal right now is just to weather seal it for the summer and then I'll redo it properly this fall. Then I'll also remove the rudder and try to replace the bushings. There's a bit of play in the rudder, not a lot, maybe half a centimeter, but worth fixing. e: the drawing at the bottom of my previous post is clearer now - the rudder post ends a few centimeters above where the hose begins, I think, while the axis continues up and through the deck mounting. I suspect whatever is holding the rudder up is hidden inside the hose. TheFluff fucked around with this message at 18:06 on May 2, 2020 |

|

|

|

Interesting setup. Looks like thatís the Teflon bushing sticking out of the deck flange on the upper bearing, and it has a notch in it that acts as the tiller stop? So the tiller head probably rides on the bottom of the cutout spot when the rudder is hanging? The stainless rudder post is kind of crazy, I canít say Iím a big fan of it. Glassing stainless is an invitation for crevice corrosion. The rusty color where the post is glassed into to hull makes me cringe.

|

|

|

|

Half a centimeter seems like a lot but if you're just lake sailing and you have life jackets on then probably ok. Also depends on where the half a centimeter is

|

|

|

|

Big Taint posted:Interesting setup. Looks like thatís the Teflon bushing sticking out of the deck flange on the upper bearing, and it has a notch in it that acts as the tiller stop? So the tiller head probably rides on the bottom of the cutout spot when the rudder is hanging? I realize I used the term "rudder post" and "rudder axis" a bit inconsistently in my previous posts - English is not my native language and these very specific nautical terms in my native Swedish are challenging enough. So to be clear, the rudder post is the tube that is fastened to the hull and doesn't move, inside which the rudder axis sits, right? The tiller is fastened to the rudder axis, which then goes through the rudder post and into the rudder itself. Let's have a look at the pictures from the previous post again:  In this picture we are aft of the rudder looking forwards. What you can see are only two things; a deck mounting (flat plate with screw holes in it) and the top of the rudder axis, complete with the hole that the spring pin was in. The travel stops for the rudder (right next to the axis) are a part of the deck mounting. The tiller head does not directly touch the deck mounting when it is installed; it only bumps into the travel stops. So the tiller head bears no load (other than the tiller itself) and neither does the deck mounting. Now, when we tried to remove the deck mounting to get new sealant in there we discovered that it would only go up about a centimeter before stopping. If you look underneath it you can see that it's actually not just a flat plate that sits on top of a hole, but rather it looks like the entire thing is a pipe flange or whatever the proper term is in English. Something like this:  So the pipe section continues below deck and it looks like it's the same dimension as the rudder post below. Now, let's look at the below deck picture.  Now we are in front of the rudder, looking aft. The stainless steel pipe is the rudder post, of course (normally it's hidden under some paneling). Then there's a rubber hose with a hose clamp in each end, where the bottom end is clamped to the rudder post and the top end is clamped to the extension of the deck mounting. What we were doing when we were trying to pull the deck mounting up was just stretching this hose. When we removed the hose clamps it still wouldn't let go so it's either glued on, or there's something else going on. We didn't want to use violence here when we're splashing on Friday so as you can see in the picture we did a very professional job holding the deck mounting up by wedging a punch under it so we could do some gelcoat patchups and squeeze in new sealant. This is absolutely not a permanent solution but for the next few weeks at least it will have to do. Now there are two ten thousand dollar questions, namely what's holding the rudder up? and where is the upper Teflon bushing? In the blueprints I have neither of these are clear at all. I think the actual rudder post ends not far above the bottom hose clamp, so the hose just sits over a void and the rudder axis itself for a bit, but I'm not 100% sure (you can see in the picture that there's a shoulder of sorts in the hose at both ends, and this view is also supported by blueprint number 76400 above). To my naive definitely-not-an-engineer mind it seems like it would make the most sense to have the bushings support the rotating axis as close to its ends as possible, which would put the upper bushing either inside the bottom half of the deck mounting or in some other kind of installation up there, but who knows. It is clear though that whatever is holding the rudder up is not fastned to the deck mounting because that one was easy to move without moving the rudder axis. The deck mounting only seems mounted to the hose. Whatever is holding it up though has to ride on something and that something might be the bushing. My hypothesis for now is that the answer to both of the questions is hidden by the hose, but I ain't touching that until I'm on land again. I'm going to keep a close eye on it, however. On the blueprint for the old skeg rudder there was also a bushing at the bottom of the skeg and I know there are some older boats where the owners have removed the skeg themselves so maybe that's a place to look for clues. Hadlock posted:Half a centimeter seems like a lot but if you're just lake sailing and you have life jackets on then probably ok. Also depends on where the half a centimeter is I can't explain how it feels in words but I'm not particularly concerned, I've been on several boats where it's been worse. late edit: on a side note, I love this old engine. It's been sitting alone and unloved all winter, but plop in the battery, put seawater intake hose in a bucket, flip main circuit breaker, turn the key, crank-crank-crank and there it goes as if it was last run yesterday.

TheFluff fucked around with this message at 18:26 on May 4, 2020 |

|

|

|

You have an incredible command of english for it not being native, thanks for your posts.

|

|

|

|

TheFluff posted:my native Swedish I generally understand it to be that the rudder/rudder-post constitute one unit, and the rudder's rudder-post is then inserted into the lower rudder bearing, which can sometimes have a rudder tube that extends up above the water line, possibly to the deck, where the second/upper rudder bearing is

|

|

|

|

Boat jargon is hard, even when you're a native speaker. I never would have guessed you weren't American, honestly; I would guess a majority of people would struggle to explain what a flange is. For me, the confusing bit is remembering the difference between the rudder post and stock - the rudder post is the tube through the hull. The rudder stock is the vertical shaft of the rudder that passes through the post. I have labeled the blueprint to help me try to describe what I think is happening in there. I'm still trying to puzzle out how this thing is supposed to work. Part number 1 is the deck fitting. What I thought was the top of the bushing sticking out is just part of the bronze casting, it's all one piece. Makes more sense, if the rudder was banging into the bushing at either end the bushing would just spin. So the 'deck fitting' consists of the pipe that goes below deck (I'm going to guess based on the picture that it sticks down below maybe 6"?). The wide bit with the holes that attaches to the deck is the flange. And above the flange is that ring with the gap that acts as the rudder stops. Below that things get murky. Part three makes sense, that's the lower bearing. It's where you expect it to be, at the bottom of the hull where the rudder is inserted. The dark part of the drawing is the Teflon bearing. What isn't obvious is where the lower bearing ends and that stainless post begins. Which also makes me wonder if they are separate pieces at all? It's possible that the lower bearing and the stainless rudder post and the upper bearing are all one piece, with the Teflon bushings pressed into either end. You can see flanges on the bushings on either end to keep them from drifting up or down the post. The post is glassed-in at the bottom, but what is happening at the top? The upper bearing can't really just be floating on the end of the rudder post, with just a rubber hose to secure it to the deck? And judging by the hose placement and bulging, it appears that the top of that stainless post is only an inch or so into the bottom of the hose, with that seems like a full foot gap from there to the bottom of the deck fitting? Unless they shoved the hose waaay down over the post and the top of it is much higher, that seems really short? The upper bearing needs to be at or very near to the deck, I'm having a hard time believing it's just floating on the end of the rudder post somewhere between the hull and deck? The drawing suggests that there is very little or no gap between the bottom of the deck fitting (part 1) and the top of the rudder post (part 2), which would make sense because if the faces of the two were touching, that would give the top the rudder post some stability. But the gap looks much larger in reality. As it is, I have to think that the rudder stock is bearing on that deck fitting and not the top of the rudder post. If the load was on the top of the rudder post, which is attached only at the bottom and only with fiberglass tabbing, the loads would crack that thing loose in short order. The rudder stock is probably just bearing on the bronze. Bronze is pretty soft and slick, so that can work for a while. Eventually, the bronze will wear too much, and you'll have to sleeve the thing somehow or have a new one made. I hope that there isn't a bushing at the top of that rudder post as the drawing suggests. If the upper or lower bearings do wear, and the stock can move enough to load the top of that post, that would be bad. I'll be curious to know what's really happening inside that hose. And this means that the rudder is probably just held in by the clamping of the tiller head and that spring pin. Is there a jack stand under the rudder? Have you tried to lower it and see if it goes down? Big Taint fucked around with this message at 02:05 on May 5, 2020 |

|

|

|

So many words about so small a project

|

|

|

|

This is why I like boats with gugdeoned on rudders.

|

|

|

|

Neslepaks posted:So many words about so small a project why don't you commission someone to post about your yaaaaacht, mister  e: no seriously tho it would be really interesting to hear about it TheFluff fucked around with this message at 21:15 on May 5, 2020 |

|

|

|

Neslepaks posted:So many words about so small a project Itís quite the puzzler, Iím really curious to know how it works.

|

|

|

|

Your thoroughness is great, fluff. I'm only jesting. As for the yaaaacht, it's corona delayed, unsurprisingly. It was far enough along before poo poo hit the fan that they thought they'd be able to deliver on time but we're 3-4 weeks off last i heard so hopefully late May. I can only wait and hope.

|

|

|

|

Turns out a lot of marine parts are manufactured in northern Italy...

|

|

|

|

Yeah just seeing this thread here, and Iím embarrassed ive allowed sailing to be discussion #1 here. Iíll give stark project updates on... day... 1. A jet ski rebuild. Building up a supercharged modified 2006-2010 sea doo with 250+ horsepower 2. A jet boat rebuild. Dual engine project challenge. Seeing if i can build a sick wake / ski lake boat for under $2000 total. Boat first, then Iíll build ski. With quarantine etc i think i can do both within next 6 weeks.

Amy Pole Her fucked around with this message at 00:48 on May 8, 2020 |

|

|

|

Hereís the ski https://ibb.co/vsyhLGq

|

|

|

|

I think I will see if I managed to knock crack my engine block over the winter this weekend. Fingers crossed.

|

|

|

Amy Pole Her posted:Yeah just seeing this thread here, and Iím embarrassed ive allowed sailing to be discussion #1 here. Congratulations, friend! I think youíve made triple the mistake I did because I only have one engine. wallaka fucked around with this message at 04:48 on May 8, 2020 |

|

|

|

|

I was just informed it should arrive in Oslo on 16 May.

|

|

|

|

Neslepaks posted:I was just informed it should arrive in Oslo on 16 May. I'm curious, are they gonna truck it there or sail it?

|

|

|

|

Truck.

|

|

|

|

Neslepaks posted:I was just informed it should arrive in Oslo on 16 May. Awesome! wallaka posted:Congratulations, friend! I think youíve made triple the mistake I did because I only have one engine. *nods* I broke out the old outboard this week. My winterization of running out of gas on the far side of the lake (sailed back, tipped the tank up to sputter into the dock) worked okay and it started on the 5th pull. Would have been three if I had pushed in the choke. Of course, the quality of the water in my trash can did nothing to assuage my guilt about running a 2-stroke in the 21st century. A couple of mornings later I saw an email from Defender in my inbox saying they were throwing in a free composite tank with the purchase of a propane Tohatsu, so I think that might be happening.

|

|

|

|

gvibes posted:I think I will see if I managed to knock crack my engine block over the winter this weekend. Fingers crossed.

|

|

|

|

Neslepaks posted:I was just informed it should arrive in Oslo on 16 May. hell yeah

|

|

|

|

Amy Pole Her posted:Yeah just seeing this thread here, and Iím embarrassed ive allowed sailing to be discussion #1 here. Money burner go brrrrrrr

|

|

|

|

Bought a neglected G.W. Invader from the mid 90's at the end of last year and have been working on getting it presentable (not that it matters because someone rear-ended my tow vehicle today). Most recently I replaced the gunk from where the swim platform used to be. Got a little aggressive with the acetone and obliterated a warning sticker. Guess I'll just have to remember not to go swimming with the boat in gear.

|

|

|

|

wallaka posted:Congratulations, friend! I think youíve made triple the mistake I did because I only have one engine. Iíve got 8 boats and 4 jetskis. Iím out of control tbh

|

|

|

|

FrozenVent posted:Money burner go brrrrrrr $1900 completed! Hoping to get ski done for similar money. I love my 4 stroke challenger but these 2 stroke speedsters are so much obnoxious fun. The GW Invader is a cool boat! Whereíd you find her? The only one Iíve seen is 16 feet with a 6 foot (iirc) beam. That looks bigger

|

|

|

|

Sail racing thread: https://forums.somethingawful.com/showthread.php?threadid=3923325

|

|

|

|

By decreasing LOA: Santa Cruz 50 (52í) Catalina 30 (30í) Boston Whaler 15 SS Ltd (15í) Flying Junior (14í) Ocean Tandem kayak (12í) SUP (12í) RC sailboat (3í) 138 feet of watercraft.

|

|

|

|

Crunchy Black posted:Sail racing thread: https://forums.somethingawful.com/showthread.php?threadid=3923325 Ciao, powerboat thread

|

|

|

|

|

| # ? Apr 24, 2024 15:37 |

|

Big Taint posted:138 feet of watercraft. Big Taint indeed.

|

|

|