|

I just used a soldering iron for the first time to replace the audio wire in one of my microphones. Today, at 40, I am finally a man.

|

|

|

|

|

| # ? Apr 25, 2024 07:16 |

|

You're not a real man unless the tip of your iron is still tinned and not oxidized.

|

|

|

PDP-1 posted:Most mathematical functions are done using op-amps of some type, a few examples being: Thank you, cool! I need to think about what kind of things one might want to do to that 0-3v to make for interesting results, I guess. And I'll be getting the hardware sometime over the next week or two. I might try a few different things, just see if anything interesting happens.

|

|

|

|

|

ran into sth i thought was very neat- electromagnetic energy harvesting with no moving parts, by replacing the usual permanent-magnet piston with a jigger of ferrofluid biased by a fixed permanent magnet. instead of needing a back-and-forth oscillation like with a linear piston, any sloshing or disturbance of the fluid constitutes useful work. it has atrocious energy density, but again, simple, cheap, did i mention no moving parts/no maintenance (this example simultaneously scavenges triboelectric AC power via the plates to increase overall generator output by ~30%) Ambrose Burnside fucked around with this message at 14:07 on Apr 26, 2021 |

|

|

|

Cojawfee posted:You're not a real man unless the tip of your iron is still tinned and not oxidized. This. I wish I knew about this before I ruined my first tip and though the iron wasn't enough so I bought a beefier one.

|

|

|

|

Cojawfee posted:You're not a real man unless the tip of your iron is still tinned and not oxidized. I watched a whole lot of YouTube videos before I gave it a go. Tinned the iron tip and tined the wires.

|

|

|

|

pressure transducer question: I want to measure the pressure of a compressed gas system fed by a liquid CO2 reservoir. Operating pressure fluctuates constantly but bounces around ~750-800 PSI under normal conditions- if the gas draw exceeds the boil-off it can swing down to 400 (or more rarely up to ~1500psi+ if we're counting momentary pressure spikes). It's also normal for the system to aspirate some liquid CO2, so this pressure sensor needs to be able to handle being splashed with extremely cold liquid CO2. Despite the pressure there's enough expansion space inside the system that the CO2 won't ever be supercritical.* CO2 is a huge pain in the rear end in this + other aspects, but the system is engineered to accept 12gram airgun powerlets and operate at powerlet pressures/flow rates, so it's too involved to switch over to compressed air. I'd like an operating/display range from nil to 1000-1500psi, that should safely allow for pressure spikes given the ~150-200% proof pressure ratings and 400%+ burst ratings I'm seeing for these sensors. Note that I can source a regulator with a built-in mechanical dial gauge for about $100, but that's a last resort, I'd very much prefer to use some flavour of electronic sensor if I can match or beat the regulator replacement cost b/c the project already has a microcontroller/datalogger hoovering up info from other sensors, and letting the computer track pressure is vastly preferable to requiring someone actually look at the dial every couple of minutes. anyways- are these  about as small as the transducers are likely to get if I don't wanna pay hundreds of dollars per sensor? Is there a different style that's more compact? I can trade on accuracy or operating range if need be, I just don't have the room to add a 1x2" cylindrical part along the gas lines I can drill into. *: Well, okay, as far as I can tell the gas is already a supercritical fluid in the powerlets (they don't slosh and balance perfectly!), but it crashes out into a Normal Meatspace Liquid immediately once pressure drops. so the mysteries of supercritical fluids remain, thankfully, Not My Problem e: a thought- the dial gauge regulator I could go with is pretty drat slick + well-integrated, so I'd be open to some hideous workaround like using optical/angular rotation sensors to sample the indicator hand position. It's back-asswards as all hell and less reliable in a couple of different ways, but covering the gauge with a lil Sampling Cap is much more workable than sticking a bigass transducer in there all protruding out the top. and come to think of it, any day where I don't have to modify a pressurized gas system in a warranty + insurance-invalidating manner is always a good day, imo. wrt the Digital Gauge-Watcher idea- anybody know of similar projects I could get ideas from? really crufty ways of pulling data from legacy mechanical indicators sounds like low-hanging fruit for EE nerds Ambrose Burnside fucked around with this message at 18:24 on Apr 26, 2021 |

|

|

|

Gas lines big enough you're talking about drilling and presumably welding bosses into, but running off little powerlets? Unless this is a handheld system, I'd definitely just tee off with some high pressure tubing and mount the big cheap sensor where you have space.

|

|

|

|

I mostly deal with ~150psi stuff, but I've never seen anything smaller than about that size. Industrial stuff usually doesn't care about being small, and a pipe fitting is going to put a minimum size on it anyway. I also don't think you'll find anything that's okay with far below zero temperatures, but is your CO2 liquid because it's cold or because it's pressurized? It will get cold when it boils, but the bulk liquid is usually room temperature (or fridge if it's next to a keg). If you want to avoid wetting the sensor anyway and don't need super fast response times, have a pipe loop to keep liquid away from the sensor.

|

|

|

|

A short run of the proper stainless tubing with a loop should be able to address all the issues at some cost to response time I'd think.

|

|

|

|

SchnorkIes posted:Gas lines big enough you're talking about drilling and presumably welding bosses into, but running off little powerlets? Unless this is a handheld system, I'd definitely just tee off with some high pressure tubing and mount the big cheap sensor where you have space. "it" is really just a modified stock class paintball gun, for the record, idk why i'm being so coy about it. I've posted about different sensor aspect of the same project before, but it's still ongoing and unpublished/NDA-bound (god its been years plural at this point); the posts always start out obtuse n vague until i realize i haven't given people enough details but yeah the project is basically adding as many non-optical/novel-to-the-trade sensors to a paintball gun as we feasibly can, using an on-board microcontroller to scrape as much sensor data as we possibly can during field testing, and (hopefully) finding some novel ways to determine complex/nuanced critical information with a high degree of confidence, based on the combined feedback from multiple cheap/robust sensor systems that can't tell you anything of use by themselves. for example, you could use a break-beam sensor in the breech to count shots fired, to extrapolate shots remaining in the 10-round tube magazine. maybe we could use capacitance to count the paintballs instead so there's no beam or eye to foul with paint. or maybe you use two break-beams in concert, one in the breech and one at the muzzle, you've got yourself a built-in chronometer, baby. and if you can determine velocity of every shot, you can predict when a gas/paint reload is necessary, alert the user- now if we add that pressure sensor in the breech, we can check the differential in the breech vs. outside, if it doesn't equalize immediately something is occluding the barrel. and so on and so on. anyways: unfortunately just sticking a bunch of tubing on top isn't a great solution b/c you really can't gently caress with the ergonomics much at all, there's no room internally to run the tubing, and any tube additions will dramatically-increase the expansion volume- more expansion volume is generally a good thing, but it's an unknown variable i probably shouldn't be adding to the mix Foxfire_ posted:I mostly deal with ~150psi stuff, but I've never seen anything smaller than about that size. Industrial stuff usually doesn't care about being small, and a pipe fitting is going to put a minimum size on it anyway. It's both cold and pressurized- there isn't enough expansion room inside the gun for all the gas from the 12gram to fully vaporize when you crack a new powerlet, the liquid fraction in the powerlet/lines is rapidly depleted by shooting regularly- if you're not mindful you can gently caress yourself by sustaining fire until the valve/powerlet ice over and the pressure crashes until the gun warms up again. Also the gun was designed to run on liquid CO2, gaseous CO2, or a combination, no attempt is made to use a 'loop' or similar arrangement to separate the gas from the liquid, the regulator is at the same elevation as the breech so for a time the gas/liquid proportion being consumed is actually partially determined by if the barrel is angled up or down. Yes, this is an exceedingly weird arrangement by modern standards, but it's also reliable, robust, fully modular, and mechanically about as simple as you wanna get. [for the record this is a stock class Phantom, if that means anything to anyone] all of this discussion is pushing me more and more towards "alter the gas system as little as you possibly can", this is not a suitable First Learning Project where teachable-moment fuckups are an ok outcome. directly measuring pressure would be great but it's really not project-critical, while " the testbed gun must be in good working order" definitely is Ambrose Burnside fucked around with this message at 23:40 on Apr 26, 2021 |

|

|

|

If it's for commercial development and you think the data is useful, you should probably just spend a few hundred bucks on a suitable subminiature sensor. It's likely peanuts in the long run vs the engineer time to robustly electronically read an analog gage.

|

|

|

|

yeah if this were serious enough to, for example. have ďa timelineĒ or ďproject managementĒ i def would. this is one of those mushy quasi-sanctioned ďit isnít in the budget but if you wanna see what you can come up with on slow friday afternoons then godspeedĒ situations. naturally it is now Scope Creep-sprawling uncontrollably in every direction at once, like a slime mould nourished by ambitious ideas and a lack of follow-through

|

|

|

|

My life got a lot better when I learned how to call out scope creep

|

|

|

|

SchnorkIes posted:If it's for commercial development and you think the data is useful, you should probably just spend a few hundred bucks on a suitable subminiature sensor. It's likely peanuts in the long run vs the engineer time to robustly electronically read an analog gage.

|

|

|

|

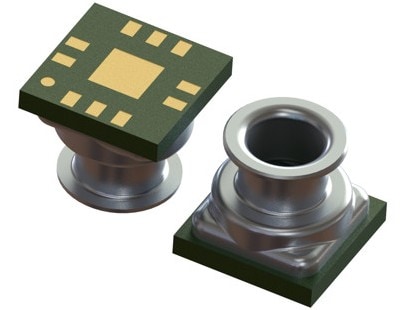

Foxfire_ posted:I doubt there's an easily findable mini transducer that's okay with that pressure and having its membrane periodically dunked in -40C liquid CO2, even with a few hundred dollar budget. https://www.pcb.com/products?m=105C12 I'm seeing stuff like this, he'd just have to get quotes I guess. Look at that cute little guy!

|

|

|

|

That company is a waste of that domain name

|

|

|

|

Ambrose Burnside posted:a slime mould nourished by ambitious ideas and a lack of follow-through don't doxx me

|

|

|

peepsalot posted:don't doxx me

|

|

|

|

|

One weird trick(tm) that Iíve seen done once is taking a cheap automotive direct injection fuel pressure sensor and potting it with something that transfers the pressure but blocks the liquid. I think it was like a 3d printed cup and some sort of jelloíy urethane diaphragm. Some sort of tiny pinhole diffuser in the 3d printed piece so that the liquid couldnít direct impinge on the diaphragm either. No idea the exact specifics or how long it lasted once installed but I did at least see it work. Or just use the sensor directly on a bench and see how long it lasts? Theyíre like $30

|

|

|

|

|

Disregard that Iím an idiot This is the perfect use case for just making a precision inline piece of tube in your gas system and getting pressure by measuring the expansion of it via strain gauge. Add in a temp compensation and youíve got a highly accurate system for next to nothing besides hours spent machining

|

|

|

|

|

Maybe a mems sensor is compatible with liquid CO2? https://www.st.com/en/mems-and-sensors/pressure-sensors.html for example though I didn't see any specific indications it was compatible with anything in particular.

|

|

|

|

SchnorkIes posted:https://www.pcb.com/products?m=105C12 I'm seeing stuff like this, he'd just have to get quotes I guess. Look at that cute little guy! M_Gargantua posted:Disregard that I’m an idiot here's how the internals work, btw- it's a Nelson design, pump-action manual cocking, about as simple as you can possibly get. flipside is that it really is just a tube, there's almost no real estate inside for adding parts, hence my despair at bigass sensors  taqueso posted:Maybe a mems sensor is compatible with liquid CO2? this is neat, i'm gonna do some research. actual pressure sensors might be the wrong way of going about this, or at least not worth getting too invested in, given the size/implementation/budget constraints here. similarly, i'm considering capacitive sensing of the 12-gram 'reservoir'/ another low point in the gas line as a roundabout way of detecting not pressure, per se, but the point at when the terminal dropoff in pressure begins, which is the data point we're actually concerned with. performance will be relatively consistent until the liquid fraction is fully vaporized and nothing is there to replenish the gas that's exhausted. if i can reliably distinguish between a powerlet half-or a quarter-full of liquid CO2 and one filled with just gas, that might be sufficient. my technical grasp of capacitive sensing is v shaky but afaik it should work: liquid CO2 has a dielectric constant of 1.6, gaseous CO2 at 1.0000somethingtiny, and the steel in the case is effectively 1. apparently you cna reliable sense stuff with constants down to about 1.2 w common techniques, 1.1 with specialty sensors, which suggests to me that the gas will be 'invisible' and only the liquid will have a detectable influence on capacitance. i've been putting of boning up on this for a while but i'm already committed to attempting a capacitive alternative to using 10 beam-break IR sensors for ammo counting in the 10-round tube mag, i can probably attempt both techniques simultaneously, make it worth my while... Ambrose Burnside fucked around with this message at 23:00 on Apr 27, 2021 |

|

|

|

petit choux posted:I'd like to trawl this thread as well for input. Been talking to the DIY musical instruments thread... Could you link me to that thread? For the life of me, I canít find it. I have ideas for some Franken-phones. Edit: found it. Marsupial Ape fucked around with this message at 03:42 on Apr 28, 2021 |

|

|

|

-wrong thread

Dominoes fucked around with this message at 08:42 on Apr 28, 2021 |

|

|

|

So, my parents have an old Hammond organ that doesnít currently work. Itís destined for the scrapbin if I canít figure out whatís wrong with it and how complicated to fix it is. Honestly the thing is probably shot, Iím sure it hasnít been serviced in decades... In any case, itís a great excuse to finally buy an oscilloscope so I can see what all his funky analog electronics are up to. Iíve wanted one for a while, but honestly, I havenít used one in a decade so Iím not exactly sure if my knowledge is up to date. I was looking at the cheaper Rigol scopes like 1054 and 1074, but Iíd love to hear gear recommendations from goons familiar with any brands. I already own and use a cheapo sigrok/pulseview digital logic analyzer, but Iím considering replacing / augmenting it with a digital capable scope so I can be lazy. Is it worth springing for an integrated signal generator? I certainly donít own one, so my option for reference waves if I need them at any point currently would be to just pump it out of a micro lol.

|

|

|

|

Buy a 1054z and be satisfied. I've never needed integrated signal generation, and the few times I've needed signal generation at all my cheap-rear end garbage signal gen I got off ebay for like $40 has been perfectly adequate.

|

|

|

|

inkmoth posted:So, my parents have an old Hammond organ that doesn’t currently work. It’s destined for the scrapbin if I can’t figure out what’s wrong with it and how complicated to fix it is. Honestly the thing is probably shot, I’m sure it hasn’t been serviced in decades... ante posted:I always recommend 4 instead of 2 for the basic reason that one of the channels will always be your trigger. The logic analyser you already have is way better than the one built into the Rigol.

|

|

|

|

Thanks guys, I love my cheapo logic analyzer actually, so Iím not mad at all to hear that it gets to hang out on my bench longer. Just so easy to throw together a trash python plug-in to decode stuff! Sounds like the 1054z it is!

|

|

|

|

Before buying my 1054z, I kept going back and forth over whether I wanted a logic analyzer in a scope. The 1054z is great, and it comes with everything unlocked, but no option for a logic analyzer. The siglent 1104 was 100 dollars more, had the ability to plug in a logic analyzer, but required paying for extra features. The rigol with the option for a logic analyzer was the same way. In the end, I realized that having a logic analyzer on my pc was cheaper and a lot more useful. My PC has more memory to store things, and it's easier to work with. And my scope can still analyze 2wire and 4 wire signals, so it's not a a complete wash.

|

|

|

|

inkmoth posted:So, my parents have an old Hammond organ that doesnít currently work. Itís destined for the scrapbin if I canít figure out whatís wrong with it and how complicated to fix it is. If you canít fix it, donít toss it too quickly. Theyíre popular with collectors and professional musicians, someone will almost assuredly want to buy it from you for parts or to repair it themselves. If youíre in the US, I can get you some contacts.

|

|

|

|

I may take you up on that if it comes to it. My mom actually tried to donate it a few times and luckily failed, before I found out she wanted to get rid of it. That said if itís not fixable, while it may be blasphemous to some, I wasnít going to throw it *all* away. Iíd rather it stay intact, but I would honestly have to consider using it for mad science before donating it since itís so inconvenient to move around. Itís got some pretty nifty looking stuff inside it, who knows what i could do with a spring reverb or what kind of horrendous sounds would come out of the tone wheels if you ditched all the busted analog stuff and spun them with a skateboard motor going too fast... Edit: if it can be fixed, I really want to bodge a micro to its guts so I can make it into a ďplayer organĒ. I certainly suck at playing music, so Iím thinking it should eat midis inkmoth fucked around with this message at 18:07 on Apr 28, 2021 |

|

|

|

What's this about super cheap logic analyzers?

|

|

|

|

SchnorkIes posted:What's this about super cheap logic analyzers? I have this one from Amazon. It hasnít betrayed me yet, but I mean, I did buy it for under 15$. https://www.amazon.com/HiLetgo-Analyzer-Ferrite-Channel-Arduino/dp/B077LSG5P2

|

|

|

|

I think I got that one for $6 on AliExpress, five years ago, and it's honestly one of the best value tools I've ever had. It's really solid.

|

|

|

|

SchnorkIes posted:What's this about super cheap logic analyzers? Depends on what you mean by cheap. This one is 13 dollars This one is 80 dollars, and there's also one that is 130 dollars This one is 400 dollars. Not sure what exactly it offers over the others. They all work with pulseview, which is free software and lets you decode a bunch of different protocols.

|

|

|

|

Cojawfee posted:Depends on what you mean by cheap. Saleae (third one) also has their own software, which I've found to be pretty good (works on a Mac, in case that matters to you). Might not be *worth* it for everyone, but it's a value add that I've previously thought was arguable as part of the pricetag

|

|

|

|

I picked up a Saleae Logic 8 before they doubled the prices for all of their units and it's been super solid for me. The Logic software is pretty good too, though I'm not sure how I feel about the redesign they've been working on. I'd say that at the time at least the purchase was worth it for me at $200. I wouldn't recommend to someone starting out that they should spend Saleae-money on a logic analyzer when there are good-enough-until-they-aren't options at less than a quarter of the price.

|

|

|

|

I would say that if you are starting out, buy the 12 dollar one. It's good enough for if you need up to 8 wires. Unless you're doing something insane, it's good enough. The only issue is that is comes with dupont connector wires, which is great for a breadboard, but not if you need to clamp to something.

|

|

|

|

|

| # ? Apr 25, 2024 07:16 |

|

It's worth noting that a lot of the $12 logic analyzers work with the Saleae software. You'll just get a nagging message saying that their software development is funded by hardware sales so please don't use our software if you didn't buy the analyzer from us.

|

|

|