|

Every car guy's dream is to have a nice garage, right? We're going to try and do that here on a shoe string budget, just like all my projects I bought my first house about 2 years ago now, and shortly thereafter married my wife. While we were looking for houses, we looked almost exclusively at houses with detached garages/workshops. It took us almost a year to finally find a place we really liked. The house met all of our requirements, albeit the detached garage was a little on the small side. It looked really big when completely empty, and the square footage isn't terrible but it is oddly shaped to use as a garage and I ended up running out of space pretty quickly. It's longer than it is wide, but not long enough for two cars. And not wide enough for two cars unless you move cars around on car dollys. It works well as a really swank 1 car garage with lots of room to work, but a 1 car garage isn't going to cut it for me, as just having one project means that everything else has to be done outside in the driveway. That got old fast. New garage is going to be built on the same lot with the house, across from where the current detached garage is. Old garage will be used just as a garage, storage, or may be converted to a small apartment in the future. Old garage was 20x28 (560sq ft). New garage will be 30x40x14, 1200sq ft. Will have two lifts, room for 4 vehicles (or 6 if stacked). Will probably have some overhead storage space in the form of industrial shelving or a loft type area.  I don't think the door is to scale, door is an insulated 18'x10' centered along the 30' wall  You can see the four corners staked out where the building will be. The plan for this garage has been in mind for about a year and a half, and the wheels have been turning for about five months now. We just broke first ground TODAY. Jesus. I am hoping to get everything assembled pretty quickly assuming everything else works out as it should.   Some assembly required Originally we were hoping to have the foundation completed in the time (2 months) it takes for the building to be produced and delivered, and long story short the buidling has been sitting here for over a month now. We had a 1 month permit holdup (for no reason!) and then after that we've had crap weather and flooding to the point where we couldn't bring in any dump trucks. When we finally thought it was dry enough to bring the trucks in, the first one got stuck.   You can see the monstrous ruts left by the truck. This was after about 85% of the water had been pumped out. That brings us to current, I got a pump from HF and pumped out the rest of the standing water out of the access drive. We've finally had a few dry days in a row and they were able to come in today and spread out the rock for the driveway and scrape the pad for the foundation. Now that the dump trucks have a compacted driveway, we can get the rest of the fill in for the pad and then start to get to work on the foundation.   I've been wanting to make this thread for awhile now, but I didn't want to be a tease because I really didn't know when we were finally going to be able to start making some real progress. Hopefully I'll have updates at least once a week. I am having a contractor prepare and pour the foundation (and do a driveway to the house) but I will be completing assembly of the building. I can't wait to get started because my current garage looks like a screen grab from Hoarders. (Lifts, presses, workbenches, toolboxes, recovery/evac machines, welders, compressors, lighting, etc.)

|

|

|

|

|

| # ¿ Apr 27, 2024 20:58 |

|

DrPain posted:Wanna buy some used lifts? Even if it was free, shipping must be a bitch! I was already acquiring tools on top of my existing collection in preparation for the garage build - and then I had an opportunity to buy out a small shop that was leaving town. So I got a 10k Rotary lift, a 9k lift, benches, carts, compressor, welder, ac recovery machine, coolant recovery machine, grinders, signage, lighting, engine stands, engine hoists, jacks, stands, tranny jack, a lot more crap and some misc tools for a really good price. I had originally budgeted and planned for one lift, and I was on the fence about selling the second lift to make back some money. In the end I decided to keep it, it will offer a lot more flexibility with work flow in and out of the garage. Budget wise, we are expecting between $40-45k all said and done. This is with $2500 budgeted for a lift, and about $3k budgeted for a driveway to the house we are doing at the same time. That's not for a turnkey building, just a prepped foundation and a pile of building materials (with budget for electrician, lighting, and doors)

|

|

|

|

Second load of rocks is supposed to be coming tomorrow for the remainder of the drive to the building location. More dirt was supposed to be here Monday but finding clean fill has been a problem lately. Everyone either has crap or is charging double the normal rate (or has a crazy load minimum, or both).

|

|

|

|

Got the second load of rocks here for the driveway, still having problems finding fill. Who would have thought that it would be hard to find dirt ... Anyway, the one supplier that has it and had been here previously is on vacation. Otherwise trying to work and find another supplier or we have to wait for him to come back - at this rate it'll end up being the same time anyway.

|

|

|

|

Our dirt supplier is supposed to be coming back from vacation today, so we are supposed to have our dirt being delivered tomorrow morning. The bobcat should be out the day after to spread and compact the loads. After that, I believe we need a compaction test and then they are cleared to start the form work. I'm going out of town for a few days (of course). I'm expecting a spread, elevated, and compacted pad when I return. We'll see how it goes.

|

|

|

|

Things happened! Hooray! Got the fill for the pad delivered, not on the day expected but while I was gone at least. When we came back the bobcat operator was working spreading and compacting the loads of fill for the pad. Once that was done, he also scraped our main driveway to the house as we are going to be pouring a concrete driveway there at the same time as the foundation. Here are a couple pictures, I believe I heard him saying that the form work was going to start on Monday.

|

|

|

|

leica posted:Awesome. You gonna let FL goons work on cars for beer when it's done? Something like that ... More progress! They started on the form work today, so presumably the compaction test came back with no issues.  We also got a TURLET     It's already dark by the time I come home now, my wife snapped these when she came home so sorry for the blurriness. Once the foundation is done and the erection of the building begins that will be all me - so we'll have lots of pictures in between severed fingers, hospital trips, and plenty of cursing.

|

|

|

|

Mat_Drinks posted:This is sweet... Not sure how I missed it before. It reminds me that I need to talk to my brother about finishing up blueprints for the garage I'd like to build. That's awesome you have so much space and can build a big garage. I'd like an automatic gate but it will probably never happen unless it is next to free. Even so, I'd need two because the main driveway would probably get one first. Project was supposed to be done August/September but you can see how that's worked out. It's nice that it's cooler out, but it really could be done any time of the year down here. There were two guys working on the forms today. They widened the footer area around the perimeter and also got the perimeter forms up. The rebar was delivered, they said they plan on starting to lay that out on Monday. Finally got a projected timeframe from him now that he has started, he estimates that the form could be completed in the coming week and ready for the pre-pour inspection. Which would put the actual pour sometime the week after that. I can live with two weeks, that's nothing compared to the waiting period to get to this point!

|

|

|

|

They've got a lot more done, but each night when I come home it's already dark so I'll have to share the pictures from this morning. They started digging out extra footers where the support columns will be, as well as 2 extra pads where the larger of the two lifts will be. They started making the rebar framing as well. Tomorrow they are going to be doing the termite spraying  for the concrete and steel building. Termites just love them some structural steel. I'd like to personally thank the building department for that, and whoever is in charge of such bullshittery. for the concrete and steel building. Termites just love them some structural steel. I'd like to personally thank the building department for that, and whoever is in charge of such bullshittery.

|

|

|

|

leica posted:Termites can come up through tiny cracks in concrete to get to the wood structure, ask me how I know. It is!

|

|

|

|

They did a lot more today, of course I'll have pictures of that tomorrow  I opted to have my contractor lengthen the pads for the lift so that I'll have a lot more play front to back with lift placement. That way I can decide if I want a workbench in front or not and not have to worry about the thickness of the wall/columns/etc. Also will make it easier to work in front of any oversized vehicles on the lift. They did their BS termite spray or whatever and then covered everything in plastic sheeting. Once that was done They laid all the large rebar sections in place. They also laid the wire mesh down, it looks they they still need to install the spacers to keep it off the bottom of the pour. He originally told me it will be ready for inspection in one week (which would be next Monday), and assuming the inspection is fine it would be ready to pour immediately following that. Judging by progress so far, it looks like we are on schedule. Pictures from yesterdays work. Looks mostly the same, more smoothing and beveling from the previous day. They also finished staging and prepping all of the rebar and mesh sections

|

|

|

|

LloydDobler posted:That's really cool, so it's like a foot thick around the perimeter and under your lift locations, how thick everywhere else? The perspective of the pics makes it look like it'll be pretty thin. No criticism or anything, just curious as someone who's never seen a concrete pour before. Yeah the footers are deeper than I was imagining in my head. The remainder of the slab will be a minimum of 4" thick 3000psi concrete. Which is the minimum recommendation for the 10k lift. The 9k lift will just be mounted to the pad. I think the angle of the pictures makes the top look thin by comparison. Pictures from yesterdays work! Nothing new today, I'm assuming they're pretty much ready to pour or waiting on the inspector.

|

|

|

|

PROGRESS! They came by on Friday and spaced up the wire mesh for the foundation. I think it is ready to pour, he is just going to put in a board to allow for a small recess where the garage door will be closing. Aside from that, it looks to be ready (to me) Today they are working on forming the main driveway for the house. That's going to be poured at the same time so they're working on getting that ready to go.   Can't wait to get started on my part! Weather is going to be perfect the next couple months (oh god please don't take that long) More pics later on. Off to work on the GTI

|

|

|

|

They got the driveway formed up for the most part today. Driveway should be inspected on Monday, with concrete being poured (hopefully) this coming Thursday. The garage slab already passed the pre-pour inspection.    DUCKS!

|

|

|

|

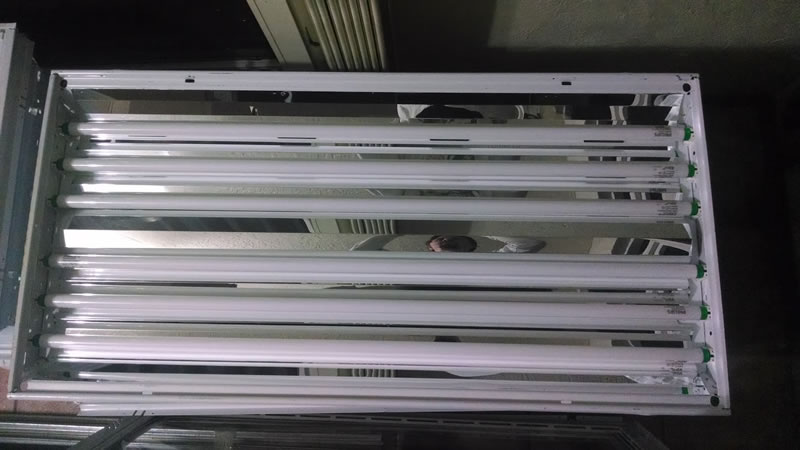

Big update today, bigger update tomorrow! Concrete is getting poured tomorrow! Concrete is getting poured tomorrow!   I took the day off of work so I should have lots of pictures of the process. I also parked all my vehicles as far away as humanly possible.  We cut down a few trees that were going to be close to the building, they weren't really in the way but they will allow the concrete trucks to get closer and alleviate the potential need for a concrete pump. Driveway will be getting poured tomorrow as well.    Last look without concrete! The three trees were later cut down flush with the ground, to allow the concrete truck access down the side of the building. I also scored some serious lighting. I had budgeted for 9x 6-lamp T8 fluorescent high bay fixtures. Everyone says to overdo it on the lighting, and I was trying pretty hard. Reviews I saw for buildings about my size said they bought 4 or 5 fixtures and could have gone with less. Wusses. While searching for Home Depot gift cards to try and save some money I found someone selling the exact fixtures I was looking for on Craigslist. I bought 10 fixtures with bulbs for less than half of what the fixtures alone would have cost me at Home Depot (and they had the best price by far!). They all look brand new or new scratch and dent. Some minor imperfections, but look 99% new. What luck!

|

|

|

|

I believe they are 32W each so 32x6x9 = 1728W or 1920W if I use all 10 fixtures. I may double the fixtures in front of the main lift so that there is extra light in the area used most. The fixtures each have two ballasts, so they can be wired with 2 switches for each fixture. That way I can turn on half the lights but still have an even light distribution through the shop. They are pouring the pad as we speak, about 80% done so far. Waiting for the next truck ...

|

|

|

|

I would have loved to use LED lighting for both the geek in me and the energy savings. And the smug. But it would take too long to justify the extra money up front. And the extra money up front is at a premium right now with everything else going on. I'll just have to change 1 spark plug more a month to cover the extra electric. Pictures and time lapse video coming shortly!

|

|

|

|

First thing this morning we had a surprise, apparently our Brown Runner ducks have come of age. Had a little surprise left in the pen after I let them out this morning.  We have one mallard and three runner males, one runner female. We noticed the rapes starting a few weeks ago. Poor gal. Anyway, back to manly man stuff. They started early, on site a little before 7am and the first truck arrived about 7:30am. The pad was done before 10am, and then they made quick work of the driveway. It doesn't look like it but there is a pretty significant change in elevation in the driveway from one side to the other but they did an excellent job and it looks like it will be a very smooth transition in and out the driveway. We used the fiber additive in lieu of wire mesh for the driveway. Hopefully that doesn't give my driveway the shits. Pictures!                    Hopefully start assembling the upright columns over the weekend. Have to arrange between my brother-in-law's and my own work schedule.

|

|

|

|

Alighieri posted:The whole driveway is just one large chunk without any rebar/wire mesh? Here in the Dallas area that is asking for cracks all over. Our ground sucks in Dallas. Ground was amazingly compacted under the drive. The fibers act as the wire mesh would, and there will be control joints as well. Plus it never really freezes down here. Time lapse of the pour! https://www.youtube.com/watch?v=0__rP3H5Gd4 And the much less exciting driveway pour! https://www.youtube.com/watch?v=Ie3a18liZWo FuzzKill fucked around with this message at 02:44 on Nov 21, 2014 |

|

|

|

It's a broom finish on the driveway and smooth in the garage. I've got the Genesis, Colorado, GTI, and the Corolla (wish it was a Celica) They're at work currently removing the forms. Hopefully I'll get a few of the upright columns up over the weekend.

|

|

|

|

the spyder posted:The rule of thumb is you want 100 lumens per sq ft. My bulbs are listed as approx 2900 lumens, but do they advertise actual output or theoretical output? I don't know how that works. The housings all have a chrome reflector behind the bulbs (which a lot don't for some reason) and are all 5000k temp. Going by the advertised 2900 lumens * 54 bulbs = 156,600 lumens for 1200sq ft so 130 lumens/sqft. This is assuming they are all on and assuming the advertised output is actual output of course. I am not a lighting expert *lightbulb chat*

|

|

|

|

I have officially gotten INVOLVED with this project, which means the letting of blood has begun. I set down a wooden beam we were using to stack the columns and it rolled off from where I left it and skinned my shin nicely. Blood was spilled before construction even officially began! Anyway, we staged/sorted most of the stack until we found most of what we would need to begin. We got two of the columns for the sidewall up (which is 4 C-channel beams) and two of the cross-brace girders up. We started working on the first endwall column and the entry door, but since the entry door could theoretically be placed anywhere, it requires cutting and drilling of the bracing girders in order to install it. It was pretty late, and we were wet and tired so we called it quits for the night. Since it is quite windy/rainy as we were working it wasn't safe or a good idea to leave the last column or entry door installed without being braced to the rest of the structure. So we took them back down and we will go back at it with the grinder, drill, and some daylight. Here is a night time potato shot

|

|

|

|

Lots of stuff happening today! Here's a pic of what it looked like in the daylight, along with the door framing that we ended up taking back down.   Santa's little helper! We didn't tackle the door at all, we started going the other direction and wrapped around half the building. All in, we're about 50% done what can be done from the ground. Not bad for two nights after a full day at work AND working in the dark. The pictures tonight didn't come out as well as the other night but here they are. I'll have some daytime shots tomorrow.     First order of business in the shop is the continuation of the Colorado project

|

|

|

|

Finally got a chance to work on it some more before the festivities began. Here's a pic of where we left off:  And here it is after a few hours in today:    We had to cut the beam where the entry door goes and drill holes on both beams, hopefully that should be the only modifications we need to do. They ship it this way so that you can place your entry door wherever you want along the side wall. The garage door opening is fully framed out.

|

|

|

|

Supplier was Ironbuilt steel buildings. From what I understand there are many suppliers but only a handful (maybe only a few) manufacturers in the USA. They were local to me and had some advantages to their design versus what other suppliers were offering. And the price was right. Got a lot done tonight, cranked at it for about 3 hours. We installed the last column, adjacent to the entry door that forms the edge of the garage door. We then installed the overhead garage door beam, the girder above it, and the 4 corner girders that are about 11' off the ground. Either I got shorted some washers or most of these bolts are supposed to be installed sans washers. We ran out the other night, and I had picked up 3 50 packs of washers as backup. We went through those tonight so I need to buy more again. A lot of the bolt holes are either slotted or are large enough so that you can have some adjustment when installing. It just doesn't seem right to not be using washers on the bolts... Here are some really crappy pics, it's kind of hard to see what's going on with the lack of lighting and shadows. More to come tomorrow.   That garage door is massive!

|

|

|

|

leica posted:What are your plans for heat mitigation during the summer? Fans. Lots of fans. Also, the building will be insulated. Here's what it looks like during the day now. We're off to go run some errands and pick up some supplies, hopefully we'll find some time to knock some more stuff out later on today.

|

|

|

|

Got the last three horizontal girders put up on the far endwall last night. After that, we decided to start (or at least attempt) the first roof beams. I don't have the lift/crane we're going to be using yet, so we'll end up either in the OSHA thread or on rotten.com pretty soon. Seriously though, we're getting some more ladders, scaffolding, and a lift for the remainder. We were able to get the beams up there but just barely and not safely at all.   The roof is all that's left structurally. Easy part is done

|

|

|

|

Picked up the lift today, along with a 12ft A-frame ladder. Should make things easier. Nothing done today, too much running around and it was raining most the evening. Hoping for some more progress in the next couple days.

|

|

|

|

We used the lift to hoist the first beam into place (which is actually 4 beams bolted together). I'm not going to lie, I was clenching most of the time. The beam overhangs the edge a bit, so we couldn't lift it up straight. We had to lift it at quite an angle to clear and then rotate the lift once the load was up there and then lower it back down into position. Took us a few hours between assembling the beams and figuring everything out and then tightening everything down.  This was our lifting apparatus. Says it can lift 650lbs. I guess it can!   To give an idea of scale, this is the bracket that holds the a-frame to the columns. It's either 3/8" or 1/2" solid steel. There is an equally beefy bracket at the top to join the two halves together. So besides the 400+ lbs of beams, there is 160lbs in brackets and 36 1/2" bolts holding it all together.  Last night, we figured it would go smoother, since it was identical to what we did the night before. Assembling and lifting the second one was easier than the first, but when it came time to bolt it in it put up a lot more fight than the other one had. We ended up getting it in place though, that was (hopefully) the hardest part of this whole project. The only 'heavy' beam left is the A-frame above the garage door opening - and that one weighs less than half what the middle frames do.     Wife has to work unexpectedly today, but my brother in law does as well. Since I have the lift I'm going to see if I can get some of the smaller beams into place by myself. It'll be nice to not have to use worklights for once.

|

|

|

|

leica posted:Did you order an existing kit or was it customized to your specs? They are (for the most part) made to order, because everyone wants different size/location doors, windows, etc. Sometimes you can get a deal on a 'kit' or a high volume seller. Got a little bit done by myself yesterday, got 4 of the 6 roof rafters installed, and 3 of the Z-channel pieces for the roof installed. After dark when reinforcements arrived we installed the last a-frame over the garage door and the last 2 roof rafters. That completes the skeleton of the building, there are 21 more z-channel pieces that run along the roof and then all that will be left is the sheeting!

|

|

|

|

By myself again right now, will hopefully have some help tonight. Managed to get 5 more rafters up into place, so 1/3 of them are done. 16 left to go and then sheeting. I anticipate sheeting being the most boring part but probably also the most rewarding part, of course.  Taking a break for now, regaining some arm strength to prepare for the night shift.

|

|

|

|

Nitrox posted:Is all this bolted or welded together? I'm trying to understand how the center roof rafters are held together. About 800 1/2 dia bolts, 500 rivets, and about 3800 sheet metal screws. Bolts are done, onto the screws and rivets :p Haven't had a chance to work in a bit, but we finally got the rest of the roof rafters up last night. There are a about 30 flange braces that I should be able to knock out tomorrow, and then we can start on the insulation and sheeting. Not sure how smooth that's going to go, hopefully no problems.

|

|

|

|

the spyder posted:Rivits? How are they fastened? I don't know! I was just looking at the manifest to get my fastener counts! Not sure where the rivets come into play, maybe they aren't really rivets but are just listed as such. If they are, I need to get a rivet gun!

|

|

|

|

Ferremit posted:On my new house all the steel facias and gutters are pop rivited together, would easily be 500 on a medium sized house roof so maybe thats where they go on the shed? It may very well be for the trim. We'll find out! I got all the roof braces installed today, so that is the final item before sheeting. They really helped to stiffen the structure up, The sheeting itself will further stiffen everything up. Here's some final pictures before we move onto the next stage.       Shop dog and duck approved.

|

|

|

|

leica posted:You have a pond in your yard too? The water looks really clear, is it spring fed? No running water around here, just marshes. A lot of lots in the area have a pond, they excavate a pond and then use the dirt from the hole to build the house up on a hill. Since this whole area was basically wetlands, minor flooding can happen anytime there is a large storm or heavy rain. The pond in my yard was actually a natural pond though, still has a few cypress tree 'knees' and stumps poking out. Just has some turtles/frogs/snakes/fish with a side of duck.

|

|

|

|

8ender posted:This guy has the right idea. Need a break from your amazing garage? Go bass fishing in your stocked onsite fishing pond. There are bass! They don't grow very large because of the pond size but they're there. I've caught crayfish, catfish, bluegill, and bass. I've seen at least 1 other type of fish as well that I'm not sure what it is. Anyway, finally have some progress to report. We got the siding up along one sidewall today. Took us most of the day, but towards the end we had a pretty good system going. This is where having 4 or 6 guys working on two or three different sides at once would be beneficial. Don't have any pictures from the back side yet, my phone was supplying the jams for the event and we didn't finish until sundown. Tomorrow I have the day off, I'm going to install the base angle for the rest of the floor, fill in all the screws we skipped over, and possibly see if I can manage to set any sheets up myself. Not going to be easy ... Once you get started you don't want to leave a wall half done, even a completed wall would suck if it rains before we finish. We'll have to scoot along now!

|

|

|

|

bolind posted:So is this like an aluminum siding - insulation - plastic sheet sandwich? Steel siding! Everything is steel except for the door jamb (but the door is). The insulation has a vapor barrier on the side facing in, the outside is just your standard looking fiberglass batting. Here's what it looks like. Need to run in the rest of the screws, trim the insulation, and cut the last sheet that is overhanging.

|

|

|

|

Alighieri posted:Looking good so far. How many cuts/bruises has the garage extracted so far? Ha. I have a large gash on my shin from the first night of work that is still healing. Had a board that was separating the columns fall while moving beams around. That was pretty much it until last night, while walking back and forth between the inside and outside during the sheeting I stood up too quickly and scraped my back on the underside of one of the girders. I have about a 5" diameter bruise on my back from that. Nothing notable besides those two. I did almost fall off the tall ladder twice during earlier construction, that will be an injury for the record books if that happens.

|

|

|

|

Working by myself most the day today, I cut and installed all the base angle plate around the perimeter of the building. I then staged all the sheeting and insulation over to the 'jobsite'. I got bored after finishing some Christmas shopping and decided to take a stab at hanging some sheeting by myself. I managed to get the first roll of insulation and the first sheet in place on my own - if I had some more clamps I could have probably managed to do a few more. I ended up waiting for my brother in law to come home and we knocked out the whole wall in about 3 hours give or take. We sheeted right over the walk in door, we figured it would be quicker to cut it in place using the door frame as a guide. I didn't get a chance to trim the overhang on the back sidewall that we left from the other day, nor did I have time to run in the couple hundred screws we skipped over (just running them in the top and bottom and moving to the next panel for now). When it's all put together each sheet will be held by 30 screws to the framing and 10 screws to the adjacent sheets. I'll have some pictures in the morning. Edit: Possibility for rain tomorrow (today), hopefully it skips over us. Not sure if anything will get done in the next couple days, but expecting a lot to get done next weekend.

|

|

|

|

|

| # ¿ Apr 27, 2024 20:58 |

|

Pictures as promised!  Starting to look a lot like shop-mas!

|

|

|