|

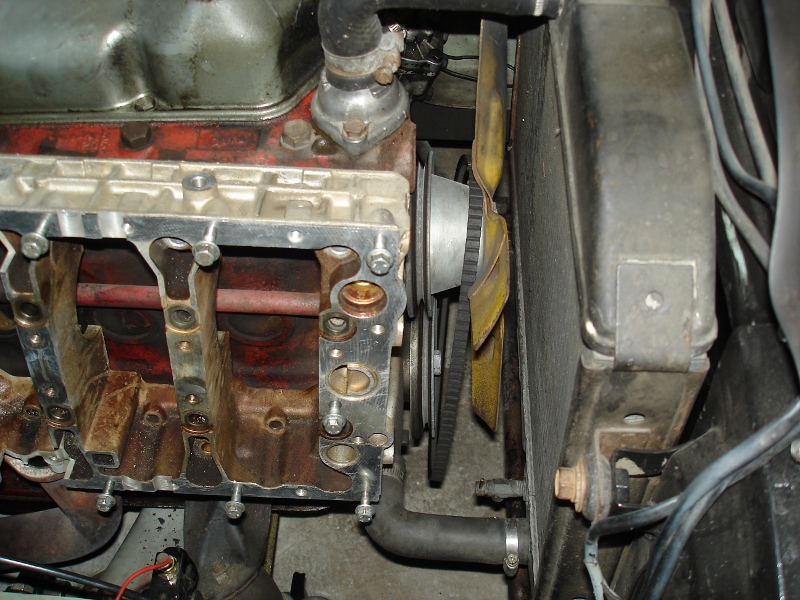

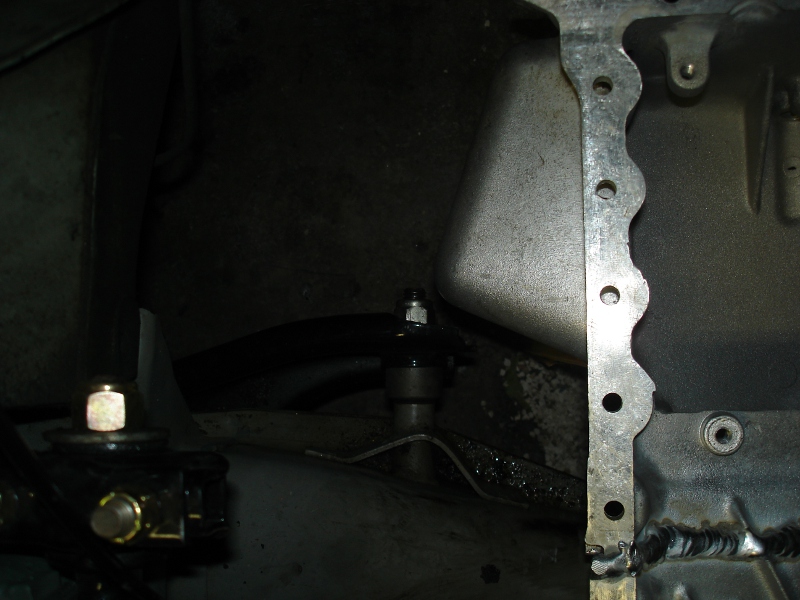

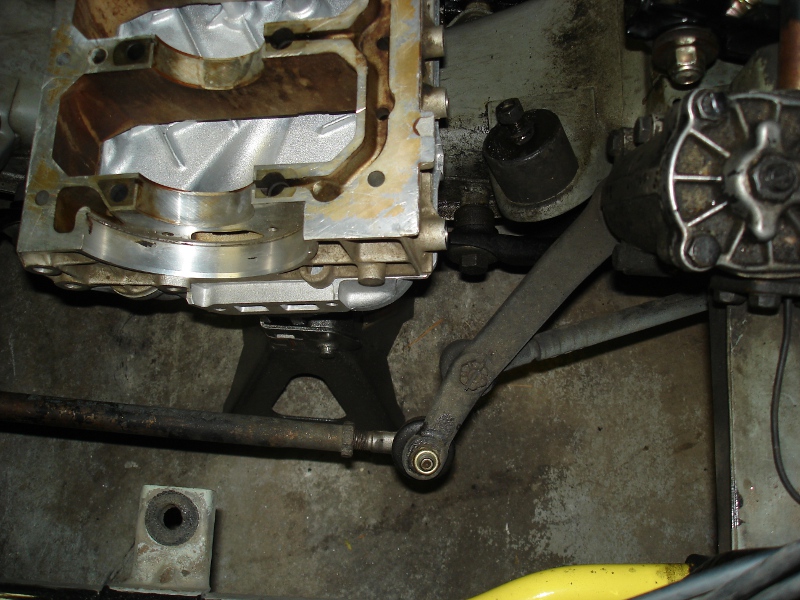

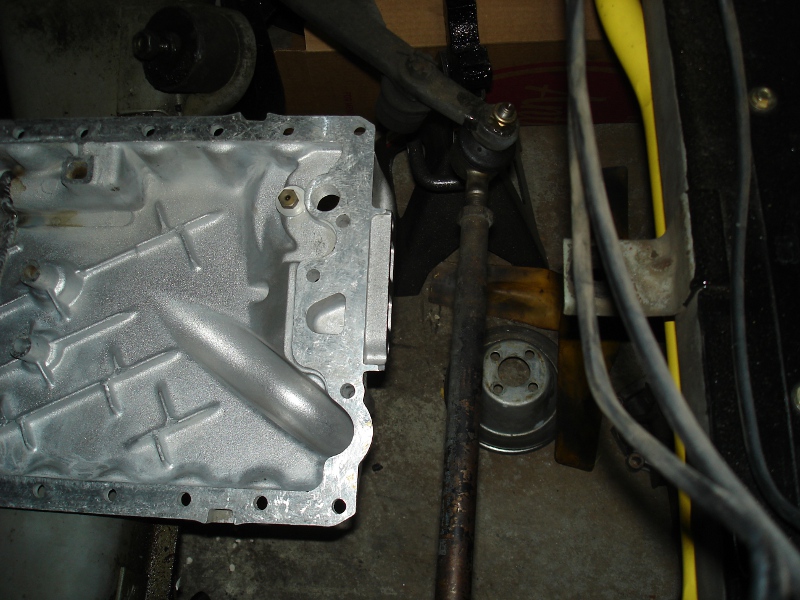

Edit 12/17/21: this project has been dragging on now for 7 years, and I derailed the thread into my other projects a few times already, so I decided to make it a general project dump rather than just about this one car. Now back to the original content. After 5 (and a half) years it's time to begin the real transformation of my '66 122 into a real monster. I'm putting a modern 5 cylinder turbo motor in it. I lost my original thread to the archives but it's mirrored here at swedespeed: http://forums.swedespeed.com/showthread.php?123266-I-guess-I-ll-be-posting-in-here-more-often... For those not up to speed, or interested in browsing a 5 year long thread, a quick history: July 2009: Purchased. Over the next 3 years I rebuilt the carburetors, stopped a whole bunch of surface rust under the front end, did a rear disc brake swap, and fully rebuilt the front and rear suspension. I got the whole front suspension powdercoated as well. At that point I had done pretty much stage 0, and this is how the car looked, and still looks. I have no further plans to modify the cosmetics, except I might go a tiny bit lower. In 2012 and 2013 I barely did anything with this car because my C70 got totalled, so I spent those years replacing and rebuilding that car. Here's that thread: http://forums.somethingawful.com/showthread.php?threadid=3503710 In early 2014 I installed an overdrive transmission in this car just to test it for sale. Other than that, I've only put 3500 miles on it in the 5 years I've owned it, for a variety of reasons. First, I work slow. It was actually torn apart for most of the first two years. Second, it has no stereo so I prefer my other cars for routine trips. Third, it has a massive oil leak due to its age. And 4th, it's gutless as all hell, it was only rated for around 90 crank HP when new. With 213k miles on it, weak compression, and Colorado altitude, I doubt it was making even 60 at the wheels. It's slow. Here's a 23.74 second quarter mile time (in a car that weighs only 2400 lb). Forgive the fact that it's shaky and silly, my daughter was 10 when she recorded this. https://www.youtube.com/watch?v=Kr41nYuGRrw In January 2012, right before I crashed my C70, I found the perfect parts car. A 1998 S70 T5 manual with only 109k miles on it. It was run down and it needed a truckload of repair work so the owners sold it off to me for $500. It had great compression and even more important, the right ecu with no bus network or immobilizer. Perfect for someone who doesn't want the learning curve of standalone engine management (me). So I parted it out and made about $1500 doing that, and the motor with wiring and ECU has been sitting in my garage for almost 3 years now. Since I just finished dialing in the C70, that's where this thread starts. In September I got motivated and harassed my friend who knows how to TIG weld into welding my oil pans. I have two, in case I jack one up. We preheated it a little hotter than this:  Then he laid a couple beads:  We tested with water and had a few leaks so he had to go over it a couple more times, but in the end I got a shortened oil pan that is only warped .040" total. I plan to fly cut it flat, but before I do that I have to check the fit in the 122. I'm presuming that I'll have to notch the pan to clear the control arms.  So a few weeks ago I started tearing down my engine:   Mmmm the coolant even after 5 years is still nice and clear. Volvo motors are so bulletproof.  The 5 cylinder engine is almost exactly the same length as the B18. I laid the bearing girdle in to start checking the fitment:  I can line it up with the bellhousing at the rear:  And it lines up perfectly at the front:  So with that inspiring confidence, it leads us to today. I had a half day of work and was able to get into it at around 2:30 and yank the exhaust and drive shaft:  And before I can get the motor out I run into my first problem, the engine hoist won't fit under my control arms.  Small problem. Jacked it up enough, engine is over and out.  GET IN ME YOU TURBO MOTOR  A closer shot of where this lump has been for the last 3 years. Colorado is extremely dry, I'm sure there's no rust in the bores but I'll check it with a borescope before I fire it up.  With the motor out I can start test fitting the oil pan. This is with it about an inch and a half off the firewall. My only concern with this is being able to get to the crank position sensor without pulling the motor.  I'm planning to mount it at the 960 motor angle that the pan comes from, so the pan has to sit way off to the driver's side. That sharpie mark on the back of the pan needs to line up with the hole in the center of the firewall.  I need to notch the pan to clear the control arm. Good thing I didn't machine it for flatness yet.   The passenger side isn't so bad, just a little off the point.  I still have another inch or more I can move it forward, until the pan hits the crossmember. I think I'll need the room, so I'll notch it with this in mind.  Here you can see how much room I have in the front still, the center grommet is where the radiator mounts.  Here it is with the bearing girdle laid down on the pan, showing the crank journals on center. Just saying, I'm not crazy and it really does need to be this far to the driver's side.  Good news here, the steering won't interfere with the oil filter. It might if I put a 960 oil cooler on though, I'll have to do more test fitting when that time comes.  And this is the cramped space where I do all this work. It doesn't look terrible in this picture but trust me, it is.  A friend got me this for christmas, and upon completing this post I'm going to have a sip. Anyone know if it's any good?  Progress as usual will be slow, but I'll try to keep this one out of the archives. Next step is to notch the pan and then onward to building motor mounts! LloydDobler fucked around with this message at 18:02 on Dec 17, 2021 |

|

|

|

|

| # ? Apr 23, 2024 22:15 |

|

Oh man am I ever happy to see this car again. This is going to be amazing. Good thing you have that sucky steering box or you'd never be able to fit this big honkin' motor in.

|

|

|

|

If I've learned anything it's that if the bourbon is from Kentucky and in a bottle, I'll like it. And I can't remember, did you already upgrade the brakes or is that in the works?

|

|

|

|

I built brackets to mount big Brembos in the front but the rear was more complicated so I stalled on it. I own the parts, but it'll come later. Part of my hesitation is that I haven't fully decided if the stock rear axle is staying. And yeah the Bourbon is pretty good.

|

|

|

|

Yes

|

|

|

|

Your Volvo is massively cooler than my Volvo and I envy you. I can't wait to see this thing done, it's going to be a monster. I like the wheel choice btw, it works.

|

|

|

|

So excited to see you starting on this (again)! The car is freaking sweet and I can't wait to see progress on it! I was looking at 122s because they look so awesome but they're awfully toasted here in AZ...

|

|

|

|

Yay! The 122's back! I'm happy to see you tearing back into this. I'm sure it feels good to be doing it.

|

|

|

|

Oh man, this is one of the projects I've been looking forward to since before I joined, this is going to be awesome.

Terrible Robot fucked around with this message at 19:08 on Dec 20, 2014 |

|

|

|

Terrible Robot posted:Oh man, this is one of the projects I've been looking forward to since I joined, this is going to be awesome. Lloyd's threads have always been gold and this one has been along time coming. It's looking great so far! Do you think it'll be on the road by summer?

|

|

|

|

So glad to see this one moving.

|

|

|

|

Thanks guys, you always make me feel so special.Wally Joyner posted:Do you think it'll be on the road by summer? Haha. Hahahaha. HAHAHAHHAHAHAAAHHAHHAHAAH. Maybe summer 2016. I really do work slow, like only about 1 week out of a month. It's a long list of things to accomplish: Fit/weld/flycut pan Build motor mounts Obtain transmission Adapt transmission to motor Cut floor Re-route brake lines (they run along the firewall with a junction block in the worst location) Build transmission mount Build exaust manifold (Nothing stock will work, even modified.) Modify intake manifold Build driveshaft Cut floor some more for driveshaft Build intake with intercooler and such Figure out a radiator Trunk mount battery Wire it up Modify ECU for coil on plug Figure out fuel pump and return Build exhaust Get it running Blow rear axle with first hard launch Ford 8.8 swap And I'm specifically NOT doing a lot of the things most guys who do vintage engine swaps do, like add AC and power steering, power brakes, rack and pinion, etc. My engine will have an alternator and that's it for accessories. Just like the original. So yeah I'm actually not joking, I don't expect to drive this car again till 2016.

|

|

|

|

Kickass, I'm excited to see this one unfold. Good luck!

|

|

|

|

Nice to see you starting on this again, the C70 thread was great. Since you're already "planning" on ditching the stock rear, have you given anymore thought on going for another brand of transmission like we spoke of in the old thread? Back then you spoke of wanting to keep it "all Volvo", but that seems to be subject to change.

|

|

|

|

While you're doing all that work, why not fit a simple stereo? Like a chinese amp from ebay with an AUX-in connected to two cheap door speakers. Job done.

|

|

|

|

Nidhg00670000 posted:Nice to see you starting on this again, the C70 thread was great. If I could find the Volvo transimssion I'd just do that, but they're getting hard to come by even for the european guys now. I already bought a Getrag 265 but I've heard the ratios suck. I guess it has a real granny 1st gear, but I could use it if I do a super low ratio rear end swap. The rear end in it now is 4.30 I think, and if not it's 4.10. The Getrag needs something below 3 to work well I hear. If I don't use the Getrag I'll probably just buy a T5, those are getting real popular for Volvo swaps of any kind. And there's tons of documentation now on which ratios and clutches and shifters to get. MattD1zzl3 posted:While you're doing all that work, why not fit a simple stereo? I already have some old used amps and it has some crappy speakers in the rear deck. I probably should. As for the doors, they will go uncut, like the dash. I'm going to make kick panels but I just am too lazy so far, and part of me was waiting to relocate the battery to the trunk. Of course at this point I'll get the car running and then do the stereo. LloydDobler fucked around with this message at 18:04 on Dec 17, 2021 |

|

|

|

LloydDobler posted:A friend got me this for christmas, and upon completing this post I'm going to have a sip. Anyone know if it's any good? I just went though a bottle of that stuff over the last month, it's pretty good stuff. The bottle at the house I'm staying at tonight ran dry last week though

|

|

|

|

Sorry to bump this without an update, don't want to lose it to the archives like I did the main build thread. I hibernated for January and February, it was so drat cold. I did mark and try to cut the oil pan for control arm clearance but I'm using the wrong saw blades so I didn't get it done, or that'd be the update. There will be some progress soon though, I'm getting the springtime rush of motivation.

|

|

|

|

Cold garages suck. How was the bourbon?

|

|

|

|

Tasty. Definitely in line with the kinds of drinks I drink straight. The problem now is that I don't drink it straight often enough to go through it, usually only on special occasions. So I have 3 or 4 bottles of premium scotch/whisky/bourbon that just sit until the holidays or whatever. Once I ran out of Crown Royal which is what I usually drink mixed with coke so I tried to mix some fancy stuff, bleah. The coke ruined it. Never again. I do have a high school friend visiting from out of state this weekend so we'll probably go through some. He's one of the guys in the famous picture of me and my friends in my first 122. It's a bummer he won't get a ride in this one, I gave his brother (also in the pic) a ride last fall when he visited. In fact, I delayed this project just so I could do that. I guess I did get something done this winter, I spent most of January and half of February parting out the old drivetrain, made about $1200 so far, to go towards this project. Still have the carbs and a steel timing gear set to sell, should net me another $300-$400 or so.

|

|

|

|

Finally, got off my rear end and got some loving motivation. Notched the oil pan. It went pretty well for harbor freight jigsaw blades and a $5 garage sale craftsman jigsaw. I only broke 3 blades and made the saw smell funny towards the end. I still need to clean things up with an angle grinder but overall it's ready to be welded back up. This side was sort of a straight cut.  And here it is laid in there, as far forward as it can go.  Here's the control arm nut clearance, all I need to be able to do is get a box end wrench on it and pull the bolt out the front so this should be fine.  I kinda wish I'd only notched this side rather than taking it all off. I lost about a half pint of oil capacity and screwed up the cut as well. I'm sure we can patch it when welding day comes. Maybe I'll put a large box outboard to add some of the oil capacity back in. On the one hand it's wasted space, on the other hand it gives great clearance for a big downpipe.  Another view of the control arm clearance. I'll probably lift it a bit higher than this.  Now I have tons of clearance at the firewall, and I've been studying the engine. All I need clearance for back here is the crank position sensor, and I think I have plenty. I should be able to actually change it with the engine in place and everything.  And still lots of room up front. I don't think I can use the front mounted oil cooler adapter though...  Here's the oil cooler adapter I was talking about. It'll hit the steering toe link if I try to use it. I'm not worried though, I can mount a cooler on the oil filter mounting location, or plumb one in to the turbo lines, whatever I need.  So I was motivated enough that I spent the rest of the night stripping crap off the motor. I'm very optimistic about the way this is going to fit.  And exhaust side, all that's left is to figure out how to remove that water pipe. I'll be using a modified 960 pipe anyway.  And looking at the back of the motor, there's the torque restraint, the crank position sensor, and one heater hose that needs a 90 degree fitting. I don't even need to seal up where the distributor used to be, it's already sealed. I will get the factory cap that goes in the hole just to keep dirt off the seal though. Ignore the spark plug wires, those are going away.  Weather's supposed to be nice tomorrow too, it was very pleasant working in my garage tonight, didn't get all sweaty. I have a lot of cleaning up to do. There was still some coolant in the motor and some oil in the turbo so those made a mess. Plus there are parts everywhere that I need to organize and box up or put in the scrap pile.

|

|

|

|

Just saw this thread. Glad to see another one of your threads, Lloyd. Always a good read.

|

|

|

|

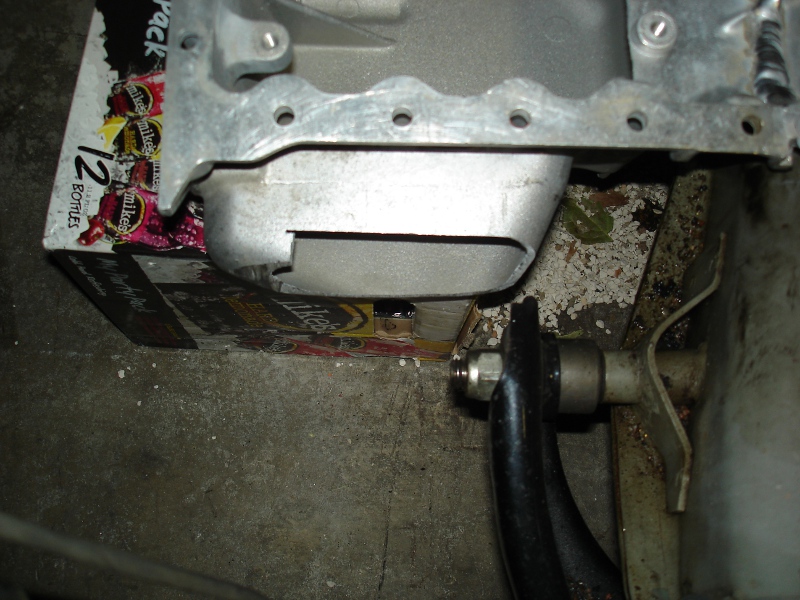

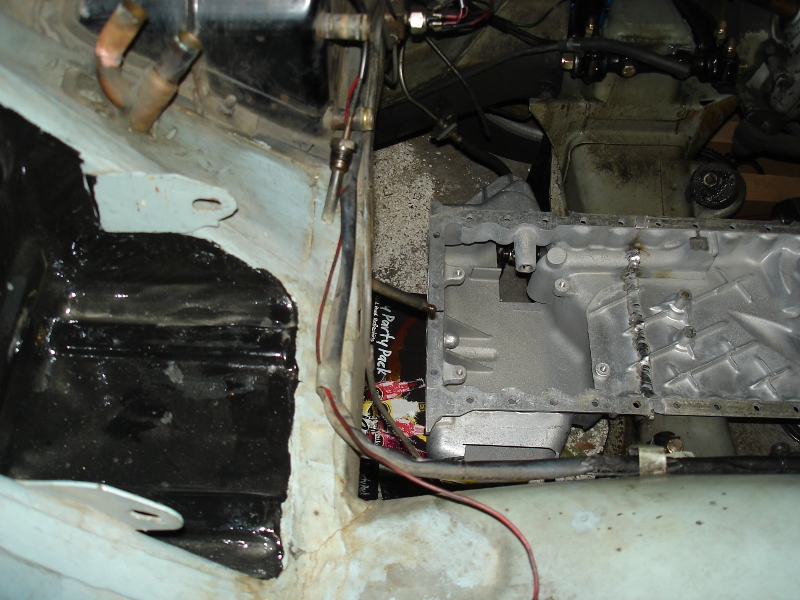

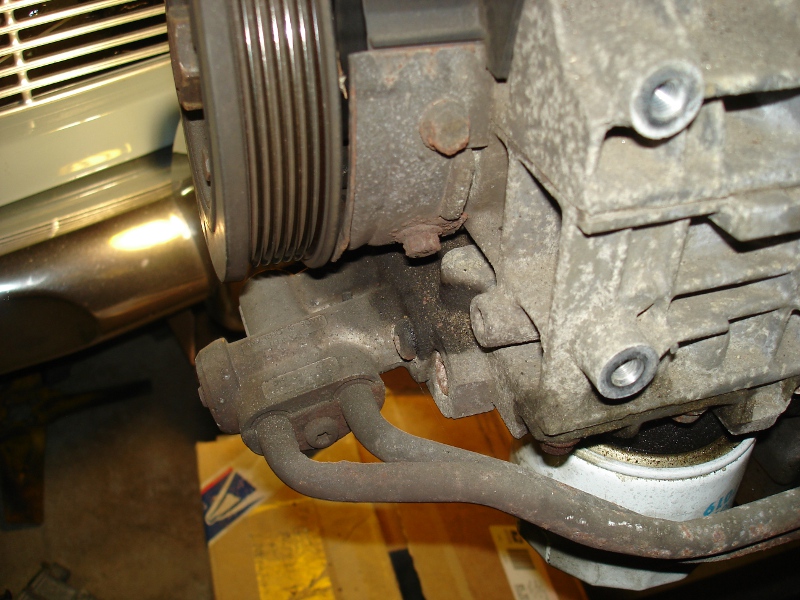

Happy Mother's day motherfuckers. My mom is 1300 miles away so she gets a phone call. Then I work on car and drink. So since my last update I finished stripping the motor. I was hoping to have my pan welded up and seal tested but my welding buddy has taken on dozens of jobs and then decided to vacation to Costa Rica in the middle of it all. I don't want to get oil or coolant on anything to be welded, but I want to make some progress. So I wrapped the pan in cling wrap:  Bolted it to the motor, silly but hey the last thing I need is leaky welds due to contamination and welder whining.  So without much further ado I dropped the thing in. It fit about like I expected. I'm resting it on a piece of 3/4" wood on the crossmember. This sets the angle correct as well as gives me clearance that I'm looking for. I mean 3/4 over the crossmember should be enough right? It's almost perfectly balanced there. Without that engine hanger it rests on the firewall, but only two fingers of force to tilt it forward. I did it this way so I can jack the car up and check things from underneath. I put a piece of string down from the center of the cowl to the center of the grille to make sure I had the axis right.  Looking down at the crank bolt I'm nicely centered there too. Maybe 1/8" off at the most.  Clearance for control arm:  Plenty of clearance on the exhaust side, lots of room for a custom manifold, all well above the control arm bushings.  A different angle of the clearance.  And at first I thought it might be too high, but it's easy to forget how high the hood goes in the front. This is one of the main differences between a 122 and an 1800. An 1800 hood will hit the motor if you don't dump it down low enough.  I'm gonna have to move this brake line here for the exhaust clearance.  So on to the intake manifold. I'm figuring on using the ME7 manifold due to the bottom inlet.  Plenty of clearance!  Especially if you lightly bend the brake line over. I think I'll have enough clearance here for any brake master cylinder I want, even if I go dual circuit from the master down. It also clears the steering by an inch or more. I'm not sure why other swaps have trouble with this clearance, maybe they don't lean it over as far, or drop it down as low as I am.  Plenty of arm clearance for access to the alignment bolts. This is very important to me, as even the stock carbs make it a pain in the rear end to adjust the alignment.  The view from the front. I have to fit a throttle body, starter, and PCV or catch can in here. I think I'm fine.  Oh crap. This is something I thought I'd have plenty of clearance for, but in this case it's wedged in there in the wrong orientation. I definitely have to source a smaller alternator. This will be a custom mount/adaptation that I did not plan on.  So I'll probably put the turbo somewhere around here:  It's way up high, I'll have to put a heat shield over it  Exhaust access isn't bad, again blocked by the brake line. Brake lines are easy enough to run.  I could also mount it a bit lower if needed, but again I'm focusing on using the space offered by the high bump in the hood, and allowing for lots of room below to run intake hoses and get access to the alignment bolts. If all I have to do is pull the intercooler hose to get in there, that's about perfect.  Side view of the lower mounting of the turbo. I will of course be re-clocking the CRHA and cold side. The straight flange hotside is about perfect for my setup, and at this point I'm running ME4.4 for engine management so I've heard this hotside works better for that, it restricts spool a bit.  So this is great news, easy access to the cam position sensor.  And decent access to the crank position sensor, it's the blurry mount past that plug and thin hose guide.  A bad camera angle but I think I have the motor farther forward than I originally planned, but that's fine. I might have to trim the end of the control arm bolt but in the end I'm happy with the fit of everything.  And a nice closing shot of the basics. Engine management will either be in the battery box or under the dash, I might invert the battery box to mount the electronics up high there behind the glove box (well, it's a tray in this car) .  So far so good, fun day with only one real surprise from the alternator. Also I can see I'll have to hog out the tunnel quite a bit from the beginning, the bell housing I have isn't going to fit in there right now at all. But I'll play with that next time. Next steps are: Start designing motor mounts (I'm not using the stock basic rubber), start designing exhaust manifold, get a 960 thermostat housing, and source possible alternator candidates. That'll be enough for now. It won't be long before I pull that heater box and start chopping up the transmission tunnel. LloydDobler fucked around with this message at 18:05 on Dec 17, 2021 |

|

|

|

LloydDobler posted:start chopping up the tranny tunnel.  But seriously, this looks absolutely amazing.

|

|

|

|

Glad to see an update LD

|

|

|

|

YEEEESSSSSS. Have you sat in it making turbo noises yet?

|

|

|

|

Well you look like you've thought this through, can't wait for more!

|

|

|

|

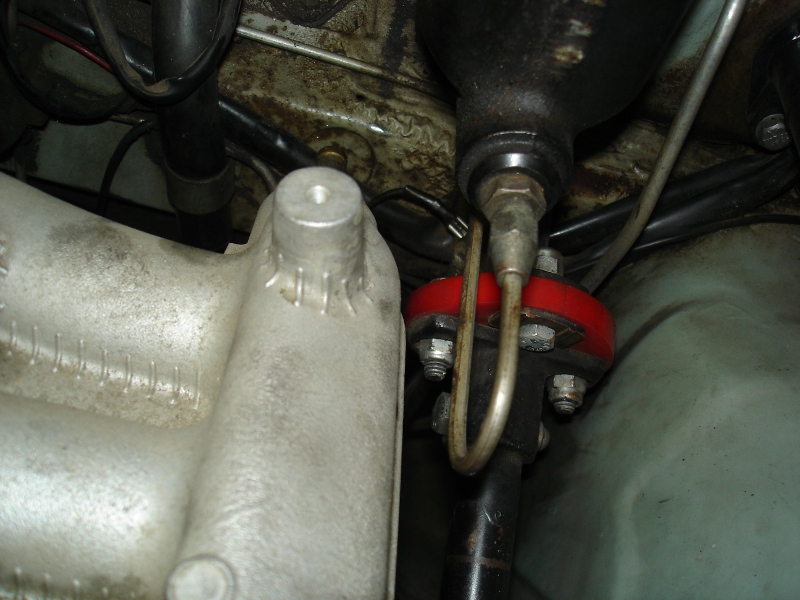

Boaz MacPhereson posted:YEEEESSSSSS. Have you sat in it making turbo noises yet? Not yet for some weird reason, it's been too crowded in my garage. Which leads us to tonight's post. After last time, I spent an evening shopping online for alternators, and it turns out the Volvo alternator is a full 6 inch diameter, which is pretty much bigger than every alt out there except for trucks and stuff. I have tons of choices, even generic street rod aftermarket ones. Most are between 4 and 5 inches around, which will leave me with at least an inch of clearance, minus adjustment. I'll have to start with a belt that barely fits on to begin with. I've also started shopping for radiators, intercoolers, fans, and planning how that's going to go together. I've done measuring and what will fit right now is about 22 x 15. Ideal would be 22 x 17, and what I've found so far is 22 x 19. Do any of you know if Eastwood's aluminum radiators are any good? It looks like exactly what I'd want. I'll also have to do some shopping for very low profile fans, although I think I have some room to stick the fan motor out in to the belt plane, the alternator belt will be very low. It just means I'll have to pull the fan out if I want to do ANY work on the front of the engine. Then I noticed that a stock Volvo intercooler is 22 wide by about 22 high. But it's 19" to the top of the fins. So I laid that in there:  I'd need to drop it about 4 inches, and it will have to go in front of or behind my sway bar, unless I also drop the sway bar mounting, which I can do. So at this point I know unless I get a really tiny radiator, I'm going to be cutting in to the front of the car where the frame rails are joined together. If we go back to a really early picture:   That beam across the front limits how low I can go with a radiator. So I think I'll cut it out, then fab a new beam (probably just some square tubing) that attaches below the frame rails and forward of the sway bar mounting. Although I could also just drop the bar and shorten the end links and nobody would be the wiser. We'll cross that bridge when we get to it. But overall that space behind the bumper is totally un-used air right now, and it would be wise of me to fill it with radiator and intercooler. Then all I have to do is cut and re-shape the lower grille sheetmetal with the V shaped creases in it to match. Which brings me to 5/22 which was my birthday. I took the day off work to go pillage the yard at my friend's Volvo shop. One of their guys is really into vintage volvos and has tons of parts in deep storage all over the building. I got super lucky and found this:  A late '67-up wiper mechanism. It uses cables and cams instead of the pre-67 swaged joints and gears, and is essentially zero backlash. My wiper mechanism is absolutely hosed and has ridiculous slop in it. Like you can freely move the wiper arms 30 degrees or more. So this was a great find and he sold it to me at a great price. Then I raided a 960. I got the engine wiring harness so I could dig out the coil pack wiring:  And grabbed the coilpacks:  Then I talked to my tuner who's going to do the coil on plug conversion, and I forgot to get the coil drivers, which I didn't know were separate on this generation. So these parts are basically useless, I'll need to use newer coilpacks which have the drivers built in. They're better anyway. And the tuner provides the wiring harness too. Then I got these coolant tubes, I've already started sawing them up to make them fit in my car. They're good for measuring and patterns anyway.  I got these motor mounts, but they're awfully big so I don't think I'll use them. I'll just do a simple superthane round bushing on each side, it'll be easier. That means I'll also be welding mount ears to my crossmember. So much for not hacking it up.  Picked up a used clutch/pp and flywheel, the flywheel is the right one for the car so I'll use it, and the clutch/pp is just for measuring. I'll buy those new.  Also bought the 960 radiator fan, it's over 4 inches thick though so I think I'll go aftermarket. Another useless part.  Grabbed the coolant reservoir, so I can figure out how to mount it and route hoses. I'll buy a new one when the time comes so it looks all spiffy.  Grabbed the throttle cable, the rad hoses, and the oil filter mount with oil cooler. The hoses and cable are just for test fitting, but I test fit this oil filter and it clears my steering mechanism so I now have an oil cooler.  I spent tonight cleaning my garage, I put a throwaway file cabinet in there so now I can store paint and chemicals in it, instead of on my bench. This table is now technically clean, these parts sitting on it are current project parts that I'm currently working on. Minus the boxes and rags of course.  Literally everything you see on this bench are screws and bolts and other fasteners/hardware. I bought wall mount drawer storage so I can organize them. I think my drawers are too small.  Hung up my old license plates (from my first 122) and the grille from my wrecked C70. it was funny that it just popped off the car, it's scratched and the mounts are broken but it makes for some nice decoration.  So that's it for tonight, I'm surprisingly tired even though all I did was clean and organize. I threw a full can of garbage away so that's good.

|

|

|

|

I sympathize with your "I have this part that I may need for the swap but probably wont use" pile. I have so many loving jeep fans for the CJ swap and I wont know if we need to change any of them until the drat thing runs and maybe cools itself or doesn't. Once the thing is done I should be able to dump two or three tupperware bins worth of poo poo.

|

|

|

|

The 5 cylinder gods have spoken!

|

|

|

|

Sometimes you just need to take stock of parts and clean up. My workbench is a loving nightmare right now. I've got a minifridge that doesn't work that needs to go.

|

|

|

|

Slow is Fast posted:I sympathize with your "I have this part that I may need for the swap but probably wont use" pile. I have so many loving jeep fans for the CJ swap and I wont know if we need to change any of them until the drat thing runs and maybe cools itself or doesn't. I have a brand new strut for a car I don't even own anymore. Just one strut. I can't bring myself to throw it out because it's new. So it just sits there in its box.

|

|

|

|

Glad to see you getting back to it, Lloyd.

|

|

|

|

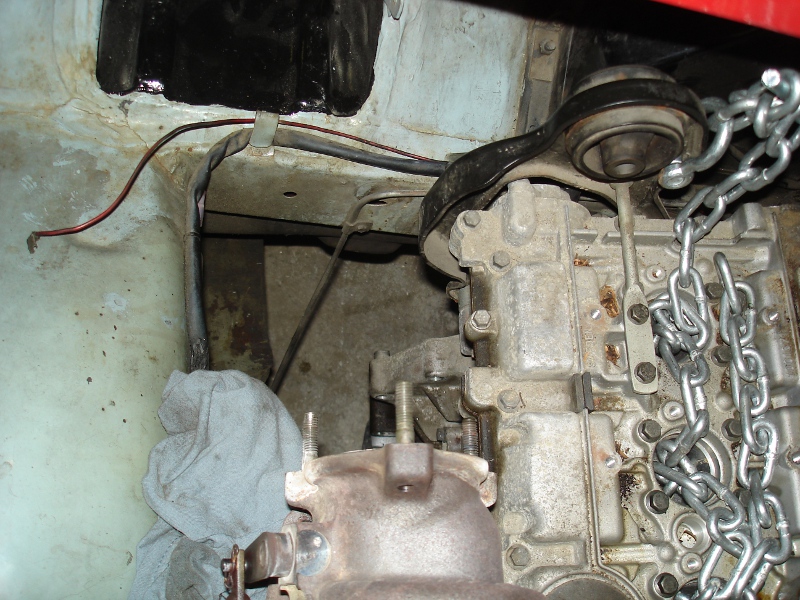

This thread needs an update, sadly I have nothing significant to report. But there's a few photos so that'll have to do. I basically took the summer off of car work instead choosing to focus on becoming debt free. I borrowed nearly $9k to build my C70, which I've been paying off slowly over the last 2 years, swapping it on to 0% balance transfer offers. Fortunately even with 3 cars that was my only consumer debt. Well, 10 days ago I became fully debt free (except for my mortgage), because I got a severance check from my job as they laid me off. So this sucks, I can't even celebrate or feel good because I have exactly two months cash before I dip in to credit again. On the plus side I've already had one phone interview and I've filed unemployment which hopefully will stretch it at least another month if it comes to that. On the car front, I removed the heater box, because it's in the way of my transmission tunnel cutting:  This will get fully disassembled and rebuilt, and I'll tuck the fan wiring in and run it out the back of the housing so it's not visible in the engine bay.  I bought polyurethane motor mounts and have been designing the mounts and brackets in my head  I removed the ignition switch and coil, this was Bosch's anti theft measure. You can't traditionally hot wire the car since they jacketed the hot wire inside a hardened steel spring case. On the other hand since the car had no steering lock or gearshift lock, all you need to hot-wire the car is your own coil. Pop hood, attach coil wires, jumper the starter and the car was running. Basically a useless security measure, even moreso now that fiber cutting discs are so widely available as well as cordless cutting tools. I mean, you can't hacksaw through the jacket, but tools have come a long way since the 60's. I'm basically trying to decide if this is valuable to a restorer or if I should just chop the coil off so I can use the original ignition switch, which I'd like to do.  Last, I decided instead of a full custom exhaust manifold, it'll save me a shitload of time if I just make an up-pipe from the original manifold. So with that in mind here's my mounting position again. You can see all I'll need is a couple pieces of tubing. I'll probably move the turbo a little farther down and a little closer to the fender just in case I ever want a larger one, although I doubt I will. I can make over 350 crank HP and over 400 ft-lb with turbos in this form factor. I also popped the snap ring so I could play with clocking the cold side, it fits a lot better in there now. Once I get the car running, a winter project will be to do a full custom tube manifold.  So my next steps are to pull the motor back out, get the oil pan welded up (I'm happy with my cuts) and lay out the plates that bolt to the engine for motor mounting. Once the motor mounts are done I'll have to make a final decision about the transmission, and then I'll buy my radiator and alternator and start fitting all that in there, along with working out the intake. I found a 22 x 16 sprint car radiator that will fit just about perfect with a teeny bit of cutting on the car, designed for V8 racing so it should be more than adequate cooling. And I've found a wide variety of alternators smaller than mine so I shouldn't have trouble when that time comes. LloydDobler fucked around with this message at 08:32 on Sep 12, 2015 |

|

|

|

Its getting the poo poo to fit thats the most fun bit of any engine swap- I remember when I shoehorned the 3.0TD motor into my old hilux it took DAYS of fiddling with the engine mounts and gearbox mounts to get the whole mess far enough back to clear the engine fan on the radiator (turbo diesel so electric fans are a no-go, just cant match the raw CFM's that a fully locked up 10 blade engine fan can when trying to cool down a diesel) I think in the end i got about 20mm between the tips of the fan blades and the radiator and i couldnt get a mm more- its at the point that changing fan belts requires you to remove a bolt holding a flexi AC hose in place and move it out of the way to get your hands in there and if you need to remove the radiator fan you have to slip a sheet of .6mm metal in front of it so you fan flex the blades enough to clear the studs on the waterpump flange. But it fits!

|

|

|

|

Sorry you got laid off dude. That ignition coil cracks me up-it's such a typical Volvo thing. I wouldn't feel too bad about cutting the switch off of it since there aren't many (any?) people doing hundred-point restorations on Amazons and it doesn't seem like there are any other Volvo switches that would work in its place.

|

|

|

|

Sucks, but you're in a decent place with no mortgage, good luck going forward. I remember discussing gearboxes a while back with you, me and my dad have been completely unable to locate a reasonably priced M90 for him to drop a D5 into his scimitar, but we did start to wonder whether the manual box from an XC90 minus the transfer case would work, any thoughts?

|

|

|

|

I phrased it badly, I still have my mortgage, I'm just consumer debt free now. I also did refinance my mortgage into fantastic terms that will allow me to pay it down very rapidly vs the previous mortgage. The XC90 is still a transverse mount motor. It has the same M56 or M66 manual as all FWD or AWD 850/40/50/60/70 series, so bleah.

|

|

|

|

Really? drat, never checked.

|

|

|

|

|

| # ? Apr 23, 2024 22:15 |

|

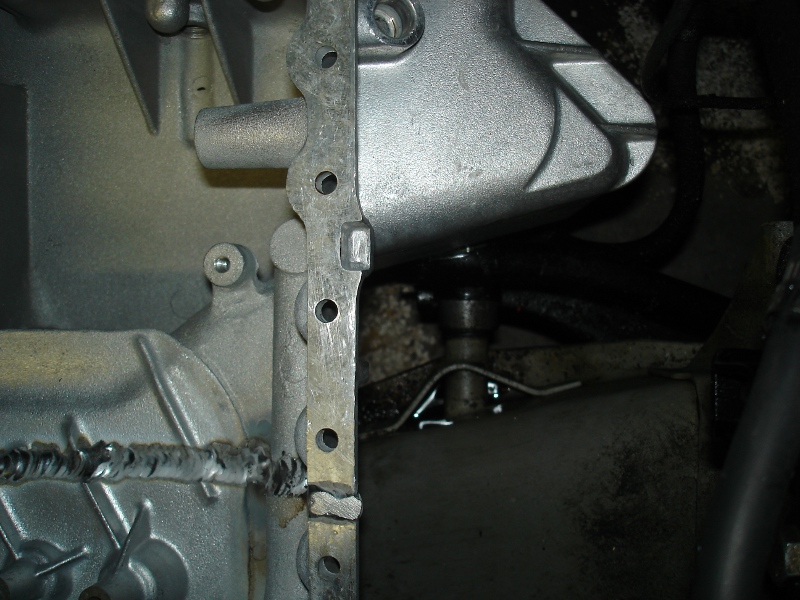

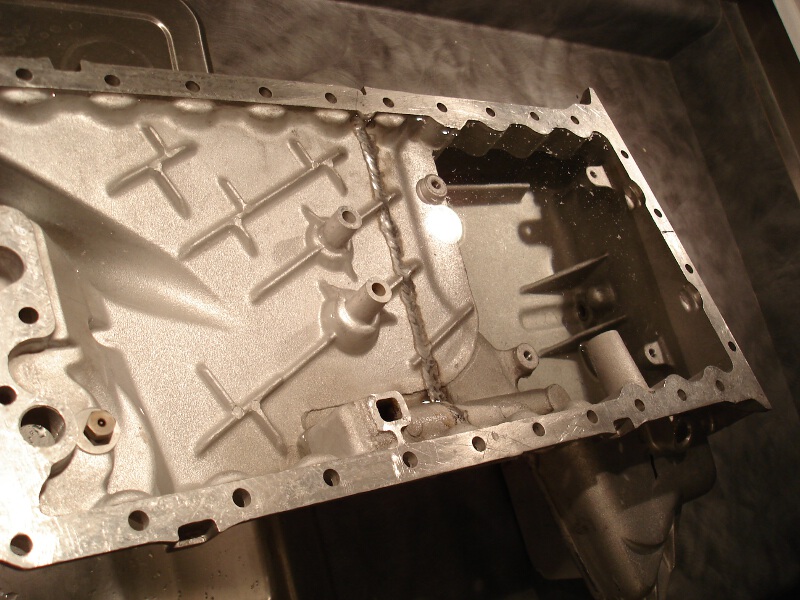

Finally have some material to update. About a month ago I did the finish grinding and made the blank plates to fill in the notches in my oil pan, and today my welder friend finally had time to help me out, and welded them all together. Initial fixturing:  First side done:  Passenger side done: The extra beads across the top were my fault due to a terrible jigsaw that wandered.  Overall photo:  And long term leak testing, passed beautifully (It's full of water in case you can't easily see it):  With that done, I also stuck the dipstick in the hole and the pan capacity to full on the dipstick is 6 quarts, which should be about perfect for the 5 cylinder motor. Other than that, I did procure an M90 transmission out of the UK which hasn't arrived yet, but that makes me very happy. Shouldn't have spent the money while unemployed but meh, who cares. It's a necessary next step. I also have designed all the motor mounts, turbo flanges, and intake adapter flanges so that I can have them waterjet cut. I'm just waiting for some quotes. Next up, once I get my flanges I'll actually drop the crossmember out of the car again so I can take it over to my friend's shop, and we can weld up the motor mounts using the pan and bearing girdle rather than the whole motor. Should work out great. I'm just going to use aluminum tubing and gusset it. And, I've been researching radiators and alternators, and I think I've found exactly what I need. A guy over on turbobricks also has found the perfect fuel pump system that is designed to convert old cars to modern high pressure delivery and return, with a baffle built in and everything. So that should be taken care of outside of filtering and lines. And it's designed to bolt in to old school fuel tanks. http://www.summitracing.com/parts/aei-18688 So I guess to update my list from earlier in the thread: Build motor mounts Cut floor Re-route brake lines (they run along the firewall with a junction block in the worst location) Build transmission mount Modify intake manifold Build driveshaft Cut floor some more for driveshaft Build intake with intercooler and such Trunk mount battery Wire it up Modify ECU for coil on plug Build exhaust Get it running Blow rear axle with first hard launch Ford 8.8 swap So now that I look at it, my goal of June 2016 will probably not be hit unless I get a job before the end of the year. On the other hand I'm already halfway to "gently caress it" and paying for everything on a credit card just to make progress, so there's that.

|

|

|