|

biracial bear for uncut posted:You need to get creative with "knock-off names" for things like that to find the models you want. yeah I figured as much. I just haven't been able to locate much

|

|

|

|

|

| # ? Apr 26, 2024 18:15 |

|

biracial bear for uncut posted:You need to get creative with "knock-off names" for things like that to find the models you want. i enjoy all the warhammer40k informal rebadging, like tau stuff listed as ďspace communist laser tankĒ etc Ghostnuke posted:yeah I figured as much. I just haven't been able to locate much I would do a ton of browsing on Yeggi using generic miniature search terms, plough through a couple hundred results and youíll get a few gems thatíll put you on the trail of what you really want

|

|

|

|

Thingiverse is dead anyway. Try Thangs.com if you don't have luck on Thinigverse. Also maybe try the names of the specific character or item from the game.

|

|

|

|

biracial bear for uncut posted:Don't underestimate autoerotic asphyxiation. Come'on. Jokes like that really aren't appropriate.

|

|

|

|

Roundboy posted:Watching a voron build with Thomas Sanladerer has me really, REALLY inspired. I see some of the issues he has with cheap kits, and the voron site itself puts out a decent packing list of the screws and things you need. I don't mind sourcing things as needed to slowly gather it all together, but is there a good resource to help me determine what is low vs high quality parts and where its needed? I get I can aliexpress the 2 kg of screws needed, but will i die in a fire if I get the aluminum extruded frames from them as well? If you get a kit you might actually pay more, depending on what you need to replace (except LDO kits, they're pretty much perfect from what i've seen) For sourcing advice: go on the voron discord. It has a bunch of vendors that are okay according to the community. You won't have much problem finding all the parts. If you have trouble finding something, just ask in the channel for your region/country. https://fermio.xyz/ and https://lecktor.com/en/ are good options, if you're in the EU. I'm very slowly building my V0, but getting the parts was relatively painless. Also kinda fun in a weird way...

|

|

|

|

If I die of autoerotic asphyxiation then that had better be the lede on my obituary.

|

|

|

biracial bear for uncut posted:Try Thangs.com Hadnít seen this one so I took a quick look and all I can say is, gently caressís sake, do they have any models that donít involve the Rockís head?

|

|

|

|

|

Bad Munki posted:do they have any models that donít involve the Rockís head? Goin' out like Carradine is much tamer by comparison.

|

|

|

|

Roundboy posted:Watching a voron build with Thomas Sanladerer has me really, REALLY inspired. I see some of the issues he has with cheap kits, and the voron site itself puts out a decent packing list of the screws and things you need. I don't mind sourcing things as needed to slowly gather it all together, but is there a good resource to help me determine what is low vs high quality parts and where its needed? I get I can aliexpress the 2 kg of screws needed, but will i die in a fire if I get the aluminum extruded frames from them as well? Join the Discord, head straight to #gchat without reading the rules, and ask if the Formbot 2.4 350 kit is a good one. Goes over wonderfully  == effort below: There aren't any officially endorsed kits. LDO is good, MagicStudios is good, but beyond that you're probably wanting either vendor kits or sub-kits. I did the sub-kits for a 2.4 (because I didn't read the rules -- you probably want a 300 Trident btw). That worked out great, OMC Stepper kit. POWGE motion kit. DigMach frame kit. It let me get good hardware without hitching the rest of my build to a particular kit's vendor's choice that day, and I wasn't ordering individual screws from BoltDepot either.

|

|

|

|

Roundboy posted:Watching a voron build with Thomas Sanladerer has me really, REALLY inspired. I see some of the issues he has with cheap kits, and the voron site itself puts out a decent packing list of the screws and things you need. I don't mind sourcing things as needed to slowly gather it all together, but is there a good resource to help me determine what is low vs high quality parts and where its needed? I get I can aliexpress the 2 kg of screws needed, but will i die in a fire if I get the aluminum extruded frames from them as well? To add to what has already been said, buying everything separately is a bit of a pain, you're better off buying partial kits or one of the few known good kits. Lots of smaller vendors sell kits of all the fasteners, or all the motion parts, or all the motors, etc (like the fastener kit here for example https://deepfriedhero.in/products/voron-2-fastener-kits or the motion kit here https://kb-3d.com/store/motion/257-gates-motion-set-for-voron-v24-300mm-1634426857215.html ) so it's good to hop on the voron discord and look at the vendors there. LDO makes pretty good kits (no 2.4 kit yet but its on the way from what I hear), and the one other generally well regarded kit can be found here https://magicphoenix.xyz/shop/, which is what I used to put my 2.4 together (and the only thing I wound up adding was a toolhead board, otherwise nothing needed to be replaced). Fabreeko and a few other vendors are starting to get into the full kit game as well. fake edit: of course I get sniped by insta. I also agree a trident is probably what you want unless you have some specific needs for what a 2.4 gives you (watching a the gantry level itself hasn't gotten old yet though).

|

|

|

|

So the trident was mentioned to me before but as a complete novice the difference is a fixed build plate vs one that moves as well ? I'm having trouble getting specific references to the updated features it has over a 2.4. Better cooling? Sturdier ? Futureproof ? Leadscrew vs belts ? I was looking at at least joining the PIF printing queue since its starting to look huge, but i need to lock in my board / hotend it seems before this can happen My original plan was a 350mm 2.4 with direct drive, a hotend capable of keeping up with the speeds i foresee, and board tbd shortly. Is there a specific reason many of you said 300 vs the 350? i see 350 is listed as stable and I might as well go big since I can, or is it just not worth it? I would really like to source things in kit form, because i am sure as hell not buying 20x20 extrusions in 1m lengths and cutting them (but it would be really cheap) but i am just a bit sour on the idea of getting everything i need to build it in one big box. Again, stupid novice but i feel the fiddly bits like screws and such can be generic, but I have seen the benefits of more 'name brand' linear rails and press fit nuts. And those little spring loaded tnuts. What does motor x (moons?) vs the off brand from ali express get me (since they are both likely made in China, if not the same factory) The hardest thing is picking out my color scheme, I really like the anodized frame colors I am seeing around. Roundboy fucked around with this message at 23:33 on Dec 1, 2021 |

|

|

|

The big difference between the trident and the 2.4 is that the latter uses belted Z drives on all four corners (a flying gantry) while the Trident uses three leadscrews to raise and lower the bed (so the gantry is fixed). They can both tram their beds relative to the gantry automatically, but the trident is going to be a bit more stable and rigid on the fast moving parts and down the road might be easier to do things like tool changers easier than a 2.4 could. I wound up going with the 2.4 because I wanted the small increase in usable Z height and because I'm a masochist who enjoys pain. 350mm is bigger but there are downsides... it takes longer to heatup (both the bed and the chamber temps as well), and its harder to tune (more belts, longer lines, etc). Also everything costs more. You can mess around with color schemes here btw: https://config.makercube.me/

|

|

|

|

Thomas had an issue in his 300mm kit where the heatbed was only 230mm big. my other fear is that I am buying parts in a kit that i am just not going to use (or be partly to building another printer...) The z height I can live with, but other then complexity Im not seeing a clear winner moving forward. Would I have more trouble with chinesium leadscrews vs belts chasing down the odd quality issue ? Thanks for that color picker, i am confirming black anodized with orange accents are kickass

|

|

|

|

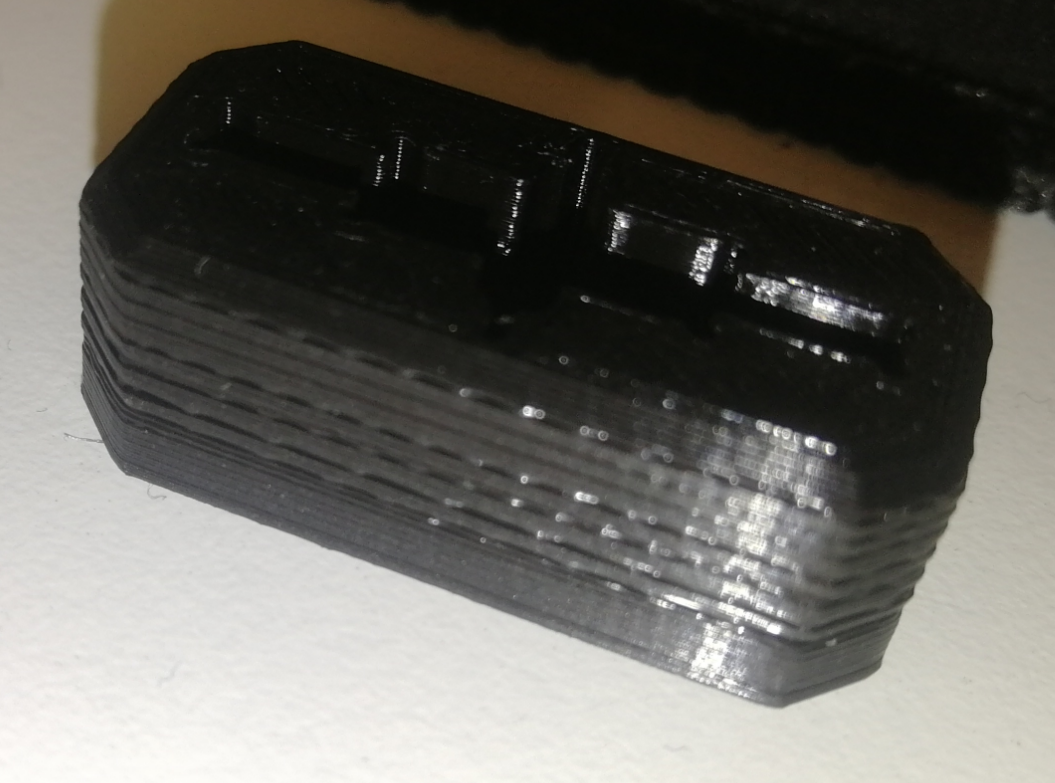

So just an academic question... why does this sort of spiderwebbing happen? I know how to fix it - this was just a prototype I knocked up using an old knackered reel of PLA, using my highest-speed/lowest-quality setting (.3mm layer height, 75mm/s speed, no infill) so I could check my idea would work before running it at rather better quality for the final product. Anyway the thing that's intriguing me is that the extruder *at no point* travels over the areas that are spiderwebbed - while it's a slightly complex shape it's still only one outside wall topographically (and I even ran through the tool motions in Cura to make sure it wasn't randomly changing the z-change spot (it wasn't, it always changed at the bottom of the piece as the sharpest angle). There's no weakness or signs of underextrusion on the layers with the wisps so it's not like the filament wasn't binding to the layer beneath and getting dragged across. Like I say I know when I print it at a more normal speed and height it won't happen so I'm not *worried*, I'm just curious about why this happens.

|

|

|

|

Anybody with a resin printer have any experience doing z-column maintenance? ran into someone saying cleaning the screw and nut solved visible layer line issues they were having, and on reflection its very odd that people mostly disregard that entire part of the machine after initial setup and tramming, and that I donít see that come up as a potential cause of a-step-related print issues. Mineís kinda grody, and since iím doing a big overhaul thanks to crashing the print bed into the tank, I thought it wouldnt hurt to address that simultaneously?

Ambrose Burnside fucked around with this message at 00:26 on Dec 2, 2021 |

|

|

|

Ambrose Burnside posted:Anybody with a resin printer have any experience doing z-column maintenance? ran into someone saying cleaning the screw and nut solved visible layer line issues they were having, and on reflection its very odd that people mostly disregard that entire part of the machine after initial setup and tramming, and that I donít see that come up as a potential cause of a-step-related print issues. I have to say itís never occurred to me to actually clean the resin printerís lead screw, but I have dropped sewing machine oil on it twice in the two or so years Iíve had it. My resin printer is covered 99.9999% of the time unless Iím taking a print off or putting resin in. It doesnít have the dog hair and dust problems that the rods and lead screws on my FDM printer have.

|

|

|

|

goddamnedtwisto posted:So just an academic question... why does this sort of spiderwebbing happen? Just because the external walls start/stop at the same point doesn't mean the infill paths do. Especially if you use the option to combine infill layers every so often (for thin wall layers and thick infill layers, like 0.1 walls and 0.3 infill).

|

|

|

|

biracial bear for uncut posted:Just because the external walls start/stop at the same point doesn't mean the infill paths do. Yeah but like I say there's not even any infill with these settings, It's basically just vase/spiralise mode but with supports. FWIW there was rather thicker webs between the supports and the walls, but I fully expected that because like I say it's just for prototyping. e: Of course - there's a big support just behind the top part there, that's probably where it was coming from as the head moved from the support back towards the bottom to start the next layer (or vice versa).

|

|

|

|

Ambrose Burnside posted:i enjoy all the warhammer40k informal rebadging, like tau stuff listed as ďspace communist laser tankĒ etc When I first started looking for models I couldnít understand why there were so many ďPrime BeefĒ models until I realized that was code for Primais Space Marine. Ambrose Burnside posted:I would do a ton of browsing on Yeggi using generic miniature search terms, plough through a couple hundred results and youíll get a few gems thatíll put you on the trail of what you really want Yeah thatís how Iíve hunted down a lot of more specific items, itís time consuming but I find a lot of interesting stuff that way. If youíre specifically looking for wargaming .stl then you can join the wargaming foundry discord where they have a looking for model channel, those guys can find just about anything.

|

|

|

|

Roundboy posted:Watching a voron build with Thomas Sanladerer has me really, REALLY inspired. I see some of the issues he has with cheap kits Meh. It's fine. I did use a Dragon HF as my hotend as I had one laying around, and I did swap the panels with haircell pattened ABS, but only because I broke one of the originals in a moment of dumb. My 300mm 2.4 prints comfortably at 300mm/s, 10k accelerations, and I haven't bothered testing faster prints because I only save a couple of minutes on a 3 hour print. My rails were clean and coast well, and the plate was tested on a surface as being at spec. I don't have ringing or other artifacts, the noisiest part of the machine is the heatbreak fan and the worst part of a larger bed is the heat soak (the Prusa XL design is really neat there) The only things that have broken are things I broke because I'm occasionally an idiot. You won't be breaking 5 minute Benchys with the official BoM either, part snobbery only gets you so far. Would I buy another Formbot kit? Yes. Would I buy a LDO kit? Yes. Have I seen badly built bling machines ? Heck yes, there's plenty of them. Take your time and do it with pride, you'll have an excellent machine that leaves many more expensive machines in the dust.

|

|

|

|

goddamnedtwisto posted:e: Of course - there's a big support just behind the top part there, that's probably where it was coming from as the head moved from the support back towards the bottom to start the next layer (or vice versa). check the "travel" box in prusaslicer and look for the blue lines

|

|

|

|

snail posted:Meh. That is a good perspective. I broke down and ordered a replacement hotend and shroud for my ender to get it back to stock and working. I can't even get the thermistor into the heatblock the old one seems to be stuck in there after my plastic mishap. I'll save my tuning for a voron build, and I realize the 5 min benchy people have all kinds of crazy parts and cooling going on, but a 10k accel klipper can make a part pretty quick. Trident 350 with dragon hotend and an octopus board seem to be what I am leaning towards, and it's going to take a couple months+ to even get the parts, so I am slowly collecting. Im split 50/50 on wanting it for actual printing vs pointing to it and saying 'i built that' From what I read, 300 vs 350 or more really comes down to the added cost and availability of things in that size. I am seeing plates, heaters, extrusions, etc in that bigger size for not crazy additional prices,. There was some talk about parts stress and stiffness at 300 vs 350, but I think that is overblown

|

|

|

|

Roundboy posted:That is a good perspective. I broke down and ordered a replacement hotend and shroud for my ender to get it back to stock and working. I can't even get the thermistor into the heatblock the old one seems to be stuck in there after my plastic mishap. People also underestimate the difference in print time and scaling. While vorons are fast, square cube catches up FAAAAAAAST. I'm pondering why voron ended up where it did. At this point the influx of people who don't "get" voron is frustrating. It always seems to be people who see core x-y and are FIXATED on that being what makes for good print quality. Or speed. Or whatever other evil they're trying to slay on their existing printer. And or the people going "I must have the best" and think there's some kind of voron magic. I need to cut off the 3d printing groups on facebook again.

|

|

|

|

Hey so dumb newbie resin question. I have my Saturn. I have have isopropyl alcohol. I have my curing station setup. I have all the safety stuff I need to print stuff. I have no idea what you do with resin between prints though. Does it just get strained and put back in the bottle? Do people leave it in the printer since itís got a cover?

|

|

|

|

Hekk posted:Hey so dumb newbie resin question. I have my Saturn. I have have isopropyl alcohol. I have my curing station setup. I have all the safety stuff I need to print stuff. I have no idea what you do with resin between prints though. Does it just get strained and put back in the bottle? Do people leave it in the printer since itís got a cover? It's fine in the vat as long as you want to leave it (I've left it 6+ months before). If it's a heavily-pigmented resin make sure you stir it up in the vat really well before printing again if it has sat for a while.

|

|

|

|

Nerobro posted:People also underestimate the difference in print time and scaling. While vorons are fast, square cube catches up FAAAAAAAST. Voron isn't magic, it's good because they throw good parts and a decent design at it. So, of course, the first thing people do is cut the BOM to the bone and scale the design to the limits.

|

|

|

|

Nerobro posted:People also underestimate the difference in print time and scaling. While vorons are fast, square cube catches up FAAAAAAAST. Yeah, a part with a lot of intricate shapes just isnt going to print nearly as fast as a flat side, even with a ton of acceleration. If I simply wanted push button quality I would just drop the cash on a prussa, but i want the accomplishment. I should probably get in on some PIF printed parts as that seems like my longest lead time at the moment.

|

|

|

|

Nerobro posted:It always seems to be people who see core x-y and are FIXATED on that being what makes for good print quality. Or speed. Or whatever other evil they're trying to slay on their existing printer. It is much easier to get better print quality on a corexy. (Assuming you get a decent extruder/hotend too). I don't see any bed-flingers getting close to the same quality. It's a huge step-up from a Prusa.

|

|

|

|

The odd things you do for your hobbies. I pulled a big paver out of my back yard, washed it off, dried it in my oven for a few hours, and am now painting it with plastidip. The wife looked at me funny on this one. Almost done setting up my enclosure the way I want it. Just need to paint the other side, stick some feet on it, throw it under my printer, and set up the camera for my raspi thatís in there.

|

|

|

|

It's starting to look like the Amazon filament I just started on a few days ago is poo poo. I've had a massive clog on a long print that subsequently failed because of it. I replaced the nozzle, and I am still seeing the same artifacts in the walls (ridges, looks like underextruded walls to me). I guess I should just trash the roll? Or is there some way to check/adjust for that?

|

|

|

|

smax posted:The odd things you do for your hobbies. I pulled a big paver out of my back yard, washed it off, dried it in my oven for a few hours, and am now painting it with plastidip. The wife looked at me funny on this one. i mean a new paver is like $4 at home depot

|

|

|

|

Hekk posted:Hey so dumb newbie resin question. I have my Saturn. I have have isopropyl alcohol. I have my curing station setup. I have all the safety stuff I need to print stuff. I have no idea what you do with resin between prints though. Does it just get strained and put back in the bottle? Do people leave it in the printer since itís got a cover? Not dumb at all. You can leave it in the vat as long as it's covered, or you can strain it and pop it back in the bottle. Either one should be fine. Some people (like me) are lazy and just stir it up before Ithey print, others worry about a leak developing somehow and ruining their machine, and pop the resin back in the bottle. Just depends on how smelly the resin is I guess, and how paranoid you are about the vat leaking.

|

|

|

|

SEKCobra posted:It's starting to look like the Amazon filament I just started on a few days ago is poo poo. I've had a massive clog on a long print that subsequently failed because of it. I replaced the nozzle, and I am still seeing the same artifacts in the walls (ridges, looks like underextruded walls to me). I guess I should just trash the roll? Or is there some way to check/adjust for that? Try drying it before abandoning.

|

|

|

|

SEKCobra posted:It's starting to look like the Amazon filament I just started on a few days ago is poo poo. I've had a massive clog on a long print that subsequently failed because of it. I replaced the nozzle, and I am still seeing the same artifacts in the walls (ridges, looks like underextruded walls to me). I guess I should just trash the roll? Or is there some way to check/adjust for that? The bolded part? That's NOT a normal troubleshooting step for when a new (to you) filament acts up, there are other things you should do first. Nozzles will last a good long while if you're printing non-abrasive filament. As the previous poster mentions, dry the filament first, and do a temp tower to figure out the sweet spot for that particular type of filament. They're not all the same. You might just have to run this filament hotter.

|

|

|

|

Deviant posted:i mean a new paver is like $4 at home depot Iím doing landscaping out there and was pulling it out anyway. It was one less to stack and haul across the yard.

|

|

|

|

Deviant posted:i mean a new paver is like $4 at home depot LOL if you think people that are into 3d printing as a hobby put any thought into efficiency.

|

|

|

|

Wibla posted:The bolded part? That's NOT a normal troubleshooting step for when a new (to you) filament acts up, there are other things you should do first. Nozzles will last a good long while if you're printing non-abrasive filament. Well yeah, the nozzle was in service for a while and I just figured it would be easier than clearing a clog (my simple attempts beforehand failed). I don't really have a good way to dry it ATM, but all my Amazon rolls so far worked completely fine, so I am confused as to why this one is acting up so much. E: Actually, this might be a temperature problem? But the temperature did stay constant all the time according to the graph.  Any input appreciated. SEKCobra fucked around with this message at 20:33 on Dec 2, 2021 |

|

|

|

smax posted:Iím doing landscaping out there and was pulling it out anyway. It was one less to stack and haul across the yard. I just tried putting a square of furniture foam underneath the paver and it really throws the silencer on it fr. I was using eva foam washing machine feet (think, like the same material as a yoga block), the print quality was about the same in terms of ringing reduction but didn't dampen any sound because it was too stiff. Anyway that's my spring recommendation. I think the pink insulation square that someone linked earlier would work too, but I didn't try it myself so I can't say if it's the same thing or not.

|

|

|

|

Thinkin' about that gag Tom did about resins a while back. https://i.imgur.com/g6meRXu.mp4

|

|

|

|

|

| # ? Apr 26, 2024 18:15 |

|

biracial bear for uncut posted:Thinkin' about that gag Tom did about resins a while back. If you think about it we 3d print on the toilet every day

|

|

|