|

ACEofsnett posted:Argghhhh, roll pins! My AR-15 lower building PTSD! TRIGGER WARNING THAT poo poo! If you have the right punch (you know, a roll pin punch) the go right in.

|

|

|

|

|

| # ? May 12, 2024 21:47 |

|

Ozmiander posted:I'm sorry, i over reacted. You always know how to make me weak in the knees. Well, maybe that's mostly the lyme disease.

|

|

|

|

That is a roll pin tool exactly like Motronic said, not a truckers sounding device, so I had a pretty easy time compared to my other rollpin based adventures.

|

|

|

|

Subaru ex-CV joint teardown last night... I got curious as to why it blew up. No significant wear on the cup surfaces, maybe a little polishing on non critical areas where the ends of the tripod joint hit it.  Needle bearings look good, so does the spherical roller, the needle bearing/roller retention clip looks kinda hammered though. Wonder why it failed?  Oh. Well there you go. That would explain the gravelly sound of things hitting the bottom of the degreaser pail while I scrubbed the grease off. I guess it was all the needle bearings and the retention clip.

|

|

|

|

Subaru can get hosed for using weirdo ujoints I have to order from some weird site on the internet instead of buying at the parts store. Rearmost ujoint in my driveshaft just shuffled off this mortal coil.

|

|

|

|

kastein posted:Subaru can get hosed for using weirdo ujoints I have to order from some weird site on the internet instead of buying at the parts store. Rearmost ujoint in my driveshaft just shuffled off this mortal coil. At least you managed to find a site selling just the u-joints. I didn't when mine went out and had to buy the entire driveshaft, at $400~ before shipping. Fuckin' Subaru...

|

|

|

|

It just blew up so bad I can't do over 50 without heavy vibrations, so I just finished junkyarding a new one. It'll last till I have the new joints to install.

|

|

|

|

Yall are making me anxious about the small u-joints in my front axle

|

|

|

|

Old shaft is out, new shaft is in, broke no bolts, tapped all the important holes ( I had to dig 3 feet of snow away from the side of the junkyard donor with a sun visor I tore off in anger (because I forgot to bring my shovel) before I could even get under the car. Need to remember to bring my shovel for future winter junkyarding. I'd say the old one was pretty much done, eh? https://www.youtube.com/watch?v=lcqT4zDs-so

|

|

|

|

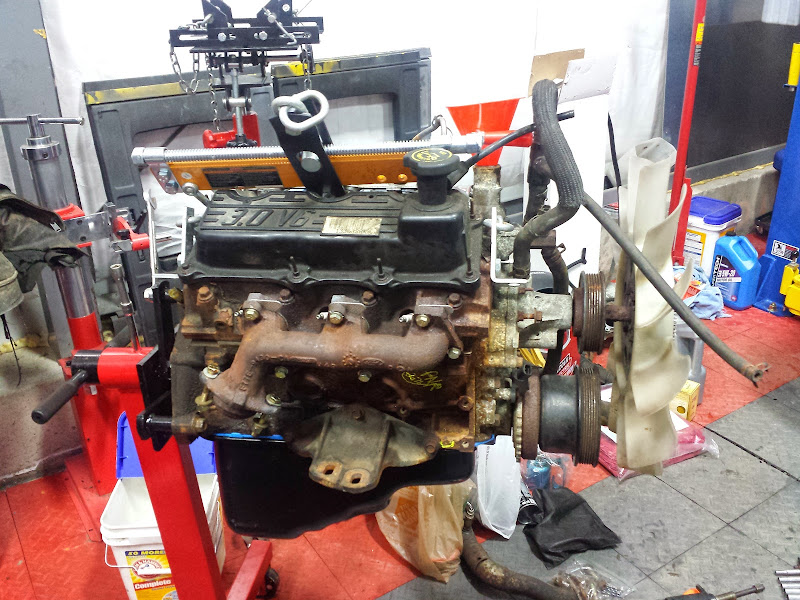

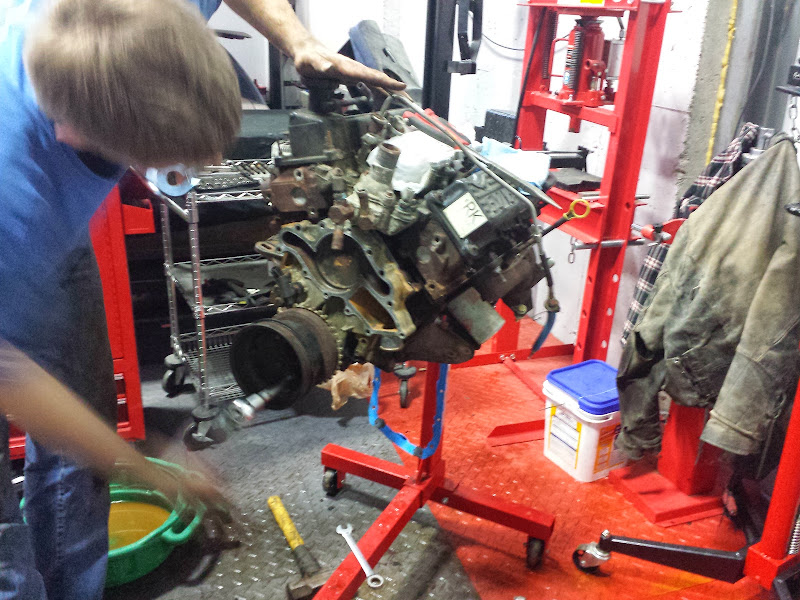

CELEBRITY GUEST POST CELEBRITY GUEST POST       Driving to NH with a bad case of beer farts. Surprised the steering wheel still has the fake wood grain on it.  Since Ken has been awesome about helping my father and I on project CJ, I ran down to NH to help Ken with project Dad Danger Ranger. Apparently Ken dad nuked the motor in his truck. We swap it. It is really cold. I would not help swap a motor in the cold. They did not seem interested in swapping a motor in the cold either. Enter... rental garage bay. I roll in and look at things that aren't a Ford Ranger.    For ace:  Cool poo poo aside.. As you browse these pictures, open this youtube and replace "DANGER" with "RANGER" https://www.youtube.com/watch?v=siwpn14IE7E New junkyard motor:   Look at all this poo poo that belongs in a dumpster:  Double tacoma dong water pump:  Some more blurry poo poo with a jack handle on the motor. Clearly making progress.  At some point we removed the motor.  I am to tired/drunk to care about the full train wreck write up, so here is how we left it.  Ken can fill in the gaps as he pleases... or repress it all Slow is Fast fucked around with this message at 06:56 on Mar 1, 2015 |

|

|

|

Ranger danger!

|

|

|

|

I am never working on a ford again after this. Further, I am never buying one. I need a god drat drink. Also, I have to finish the project today. List of things I want to do right now: Anything other than working on a ranger, up to and including slamming my dong in a car door for the same amount of time List of things I don't ever want to do: Put an engine in a ranger gently caress it. I hate this project. Ford engineers are retards.

|

|

|

|

Never done a Ranger but that 2.0 in my cousins Escort was the worst loving engine swap Ive ever done, and Ive done a goddamn ton of them. gently caress fords forever.

|

|

|

|

Ranger, ranger, high voltage! When the oil pump shaft touches, when the cam synchronizer bearing and the race kiss!

|

|

|

|

I think the lyrics to Bite Me are more appropriate

|

|

|

|

angryrobots posted:I think the lyrics to Rape Me are more appropriate

|

|

|

|

gently caress FORD FOREVER That haze in the lower right corner is my other middle finger, don't worry. According to timestamp, the motor was in and bolted to the trans at 6:45.  At 10:20 IT LIVES AGAIN (this time with all 6 anaemic cylinders firing!)  Dan I think you forgot something  A few things. Huge thanks to Slow is Fast because otherwise this thing would be a charred hulk in the woods behind the shop right now. Also, if anyone in the north shore/southern NH area wishes they had a heated shop with a lift and a tire machine... look into Ratchet Heads in Newton NH. It is where we did this, and if I was within range on a regular basis and didn't have the shop at work to use whenever I want, I would drop the membership fee in a second. My dad just signed up for a membership, so we will likely be back when the transmission has to go into this thing. Full story on all the poo poo that happened in the last two days tomorrow I guess.

|

|

|

|

SATURDAY We roll into Ratchet Heads and begin the teardown. coilpack and bracket off. We discover part of the exhaust noise is that the rear upper passenger side manifold studbolt has broken in half (  justfordthings.txt) due to having the extra load of the coilpack bracket hanging on it. justfordthings.txt) due to having the extra load of the coilpack bracket hanging on it.upper intake off radiator drained alternator and bracket off We decide not to drain the AC system, so that means the PS pump and AC compressor stay bolted to their bracket and are ratchet strapped off to the side against the radiator. Several of the mounting bolts are buried deep in the grundle of the bracket behind the belt tensioner, so those come off with much cursing. gently caress you for using a Torx in a spot too limited to get a Torx bit on it without pulling the fan off, Ford. Harness peeled off motor Fuel line disconnected Dan removes several bellhousing bolts, but the remainder are too inaccessible or seized to move without lifting the truck. We determine that one of the AC lines is routed such that the water pump and/or fan need to come off. This entire time, I've had CLR brewing in the "new" engine. The coolant in it looks roughly like a bad bout of cholera combined with an entire case of PBR the night before. We drain the new engine and begin flushing it. After about two hours of blasting water through it with it STILL coming out rusty, we give up and decide to flush the system a few times once it's been driven. We remove the water pump and fan from the old engine so that it will clear the AC line. I begin loosening the bolts holding the water pump to the new engine. Coolant immediately begins pissing out from between the timing cover and the block. My dad does not understand why I am so pissed about this. In fact, he is downright cheerful about it, until he realizes I am still mad, at which point he begins haranguing me for being mad. This does absolutely nothing to improve the situation. I somewhat calmly inform him this means that CLR and our beautiful buttmud-coolant maelstrom are currently flowing down into the oil pan I already installed, and further, that this means we need to tear the timing cover off and redo that gasket, wasting further time. Crank pulley off. Harmonic balancer off. Timing cover off... and I discover that the back of it around the coolant ports is corroded, which lines up well with the coolant stains everywhere. Oh well, I guess it should have been done anyways. Replace the front main seal, since it's right there and easily accessible at this point. It was stuck in there REAL BAD so I'm glad we did. Tear the oil pan off, it's full of CLR and buttmud as expected. Flush it back out, again. Throw everything back on. I used a bit of RTV on the gasket around the water ports due to the pitting and corrosion. No loving way do I want that leaking, I am NOT going back into this to fix it again. I decide to swap the CPS from the old engine to the new one, since we know that one works and the connector is a little damaged on the junkyard one. If this was a movie, the soundtrack would have a glissando right here. One of the loving bolts (Ford loves microscopic bolts with improper corrosion prevention coatings into cast aluminum, gently caress YOU FORD) immediately snaps off. Without further ado I decide we're using the junkyard one because I am NOT breaking the other off and redoing the timing cover, again. Harmonic balancer back on. Crank pulley back on. New water pump on. We decide we've done all we can topside and put the truck on the lift. One manifold to Y-pipe bolt obliges me and breaks off immediately, just like I wanted it to. The others laugh and round off instead, or I simply can't get a wrench on them at all. So I bust out the 3" cutoff and begin cutting things with wild abandon because gently caress it this poo poo aint going back in. 3 bolts down... one to go. Of course, that one bolt is completely inaccessible because Ford buried it deep in the vehicle's lower intestine. I can barely get my finger on it, let alone a cutting tool. One of the mechanics insists on trying his magical rounded bolt remover and fucks around with it for 20 minutes. I humor him because I have no better ideas and don't really feel like doing anything anyways. We get a couple more BH bolts and the torque converter nuts out. At this point the catcon needs to come out since otherwise the Y-pipe will never fit out of the vehicle, so we cut the fasteners off only to realize that the flanges still aren't separating. We are offered a cordless sawzall, which immediately cockblocks Dan by running out of battery. He says gently caress it and uses it like a hacksaw, which worked surprisingly well. We get the starter off and try and get the lower BH bolts out. They are in there loving TIGHT, or so it seems. M12x1.75 thread, 65mm long, 15mm flange head, ISO PC 10.9. I say gently caress it and put a ujoint and twenty feet of extension bars on, then attach my "time to gently caress everything up" 3/4" harbor freight ratchet to it. The bolts turn, but scream and stick and have to be worked back and forth to go anywhere. One seizes and will only turn 1/8 of a turn either way. My dad is happily noting that they are turning, which is good! I try to tell him how hosed we are because I know they're threaded into cast aluminum and the back of the hole is open to the elements (gently caress YOU FORD ENGINEERS) but he's not hearing it, so he keeps being cheerful and annoying me while I fight the bolts out an eighth of a turn at a time, screaming and creaking and popping the whole way. My worst fears are verified when the bolts come out. The last 3 threads at the tip of each had seized to the aluminum cast bellhousing and stayed in the bolt threads, then been dragged over every other thread we need in the bellhousing on the way out. The engine will come out now, but the new one won't go in till we do something about this. Much cogitating, cursing, and several threats of pushing the truck out the door and setting it on fire are made. We drop the truck on the ground again and attack the upper BH bolts with a variety of 15mm wrenches. Several need a regular box wrench so that the angle in the handle keeps the wrench out of the firewall, another requires my elbow ratcheting box wrench since it's got a stupid loving trans breather tube bracket OVER it (gently caress YOU FORD ENGINEERS) and another requires a gearwrench. We've still got that one damned exhaust manifold bolt to deal with. Since the motor isn't going back in, we decide to rip the manifold off with it and see what happens. Two upper bolts break (as expected), one spins out, 3 lower bolts spin out, manifold loose, cut the last manifold to Y-pipe bolt and fling the stub into the woods in retaliation. We finally pull the motor around 8pm. It requires 3 sets of hands and very slow maneuvering to get it around all the things in the way. We call it a night around 9:30, 12 hours into what should have been a 4-8 hour project. SUNDAY I and my dad split town in half and each drive to every auto parts store we can think of, looking for M12x1.75 helicoil kits anywhere we can find them. We strike out, and decide that since M12x1.75 works out to an SAE 0.47-14.5 UNSF (Unified National Sorta-Fine) thread, we'll just drill and tap it for a 1/2-13 UNC thread and throw grade 8 bolts in there. The torque specs are close enough to be explained by the difference in tooth helix angle, whatever, don't care. He goes to Ratchet Heads (they aren't officially open Sundays, but one of the mechanics was planning on working on a personal project then anyways and took pity on us, don't count on this happening for you) to measure the length of the bolts and in doing so, realizes said mechanic just so happens to have an M12x1.75 helicoil kit in his loving toolbox. Whoops, we should have asked him first. I show up and we drill and tap the BH for the helicoils, then loctite them in. We grab the new power steering lines (the ones on the truck were solid but severely rusted, and they're impossible to reach with the engine in, so we elected to replace them while it was out) and put them on. The power steering cooler barb ends up getting broken due to a minor argument which I decided to stop arguing on and just do what my dad thought would work, so now he gets to buy a new PS cooler and maybe he'll listen to the semi-professional mechanic next time. Oh well. We throw the oil pan and a few other ancillaries back on the engine, prep the exhaust parts the rest of the way, and drop the engine in. Naturally it won't line up and the load leveler keeps trying to eat the firewall. We get it almost lined up but it's clocked wrong and not straight so the motor won't yaw to line up with the torque converter snout, so we pull it back out and readjust the leveler. Turns out if you're putting a 3.0 vulcan into a ranger, you want an HF leveler, skip two chainlinks, put the chain brackets on the top hole at each end of each head, and put the shackles on the closest together set of holes in the leveler bar, that way it misses the cab cowling and firewall entirely. We drop it back in and after about an hour of dicking around with it, the dust shield falling off and getting in the way, etc we get it lined up and I get one lower BH bolt and alignment dowel lined up. YOU'RE MINE NOW, BITCH The other one lines up too after a little fighting. We get the engine onto the mount studs and now we're home free basically. All BH bolts are spun in, tightened, mounts bolted down. We get the truck back in the air and put the exhaust and starter back on. Back on the ground, it takes an hour or two to put all the bullshit on the top of the motor, fill it with oil and coolant, and prepare for First Start. ... it cranks forever. Won't start. I have no electrical debug tools with me. We have no spark and no injector pulse either (used a 194 bulb as a test light  ) gently caress. ) gently caress.We begin brainstorming. I immediately finger the CPS, cam synchronizer, or throttle position sensor as our suspects. The mechanic (nice guy, but like most, doesn't know electrical theory that well) insists we probably blew up the ECU. I swap the ECU just to prove that wrong since I had a spare sitting 5 feet away, it does nothing. He says it might be an adaptive one that has to be kept with the motor, which it isn't - that's sometimes true but generally only if you have networked sensors on a data bus rather than dumb sensors giving some sort of pulse/voltage/resistance signal. He says maybe grounds, we check em for the hell of it, but I know it's not grounds. We ignore the cam position sensor since it's brand new and we're pretty drat sure we got it timed perfectly on TDC compression. This leaves... the crank sensor. Remember how I already broke one bolt off in that drat thing? And it was somewhat damaged? I finally run out of things to hope it might be, and am left with the crank position sensor. Time to face the music and gently caress with this piece of poo poo. I go to unplug it and... guess what? It's not fully plugged in. The connector won't seat. I thought it clicked in place when I hooked the harness back up but it turns out the tweaked housing didn't click in right. So I straighten the plastic with a pair of pliers, it clicks in... turn the key AND IT STARTS!!! Sounds great, too. Better than it has in literally years. Great oil pressure, no bad noises. Only took a solid 22 hours of work - I can do a Subaru motor swap in like 3 hours, and a jeep engine swap in like 8 if everything goes wrong, but this thing just sucked rear end. Things I've learned in this project: gently caress ford. Seriously. It's never the ECU. This was a Ford, so it might have been, but it drove in under its own power so I didn't think it would be. Ford engineers are retards. Here are a few serious design sins they commit on a regular basis: * undersized hardware, especially on exhaust where it will gently caress you worst. M8 is not big enough for an exhaust manifold to head fastener, I don't care what your loving FEA or bolt clamp load chart says. Use M10 or preferably, M12. Just do it. * the goddamned stud-bolt. These are basically a bolt, with a stud on top of the head, which may or may not use a different thread spec. I swear ford engineers have a fetish for these damned things. The exhaust manifolds, upper intake manifold, a bunch of wiring harnesses, oil filter drip funnel, several accessory brackets, a half dozen grounds, the power steering rack, a bunch of heatshields, and any number of other things are held on with them. They are loving STUPID, JUST STOP. * oversized, overly strong hardware, especially on exhaust where it will gently caress you worst. M12 is way too god damned big for an exhaust manifold to Y-pipe fastener, especially when it's tapped into the expensive part, open to the elements on both sides, and will rust in. See next point: * tapped through holes where not necessary. Examples are the upper row of manifold to head fasteners, 2/3 of which snapped off and required being drilled out with carbide bits and helicoiled, the exhaust manifold to downpipe fasteners, which were too big to snap off due to rotten reduced-head bolts and required being drilled out and through-bolted as well, and the lower two bellhousing to block bolts, which were threaded into open-end holes in cast aluminum and had to be helicoiled. There is no reason for this, if they'd just put the bolt in from the other side it would have spun right out in minutes like the other 4 bellhousing bolts did. * improper corrosion prevention coatings. If you're putting a bolt into cast aluminum, it should be coated with something that will keep this from being an issue, for example some phosphates, cadplate (horrible, but it works) or a few other things. OR JUST DON'T loving DO THAT. Alright, that's enough drat words. Jesus gently caress that project. kastein fucked around with this message at 17:27 on Mar 2, 2015 |

|

|

|

I'm glad I was able to be helpful. After looking at all that poo poo and horror that I saw... Nope nope nope I have spare sockets and 6 pairs of fingerless dewalt gloves, get them back to me whenever no worries. The header to Y pipe bolts were probably the most retarded thing I've ever seen. Hey lets put an O2 Sensor in the way of undoing the last bolt good idea guys. Also if you ever have to touch the water pump, you have to reseal the timing cover too. gently caress that. And the hardware that doesn't make any sense and breaks off. I mean Yeah I'm used to some dumb poo poo on the mustangs, but dear lord the ranger was bad. I think we came to the conclusion that it designed by retarded toddlers with a parts bin and cut and pasting CAD files around until nothing intersected. I wonder what the worker dudes thought... "yeah those poor fucks are remotoring a ranger".

|

|

|

|

I think that you aren't supposed to have to regasket the timing cover, but it'd been leaking for a while and letting the tension off resulted in instant failure. There was an assload of coolant and buttmud residue on the outside of the block near there that we were wondering about anyways. Any chance you ended up with a 13mm shallow Husky 1/2 drive impact socket or a 14mm 12pt shallow Evolv 3/8 drive socket? I think I saw them both Sunday, so I doubt it, but they're AWOL and seem to have disappeared into outer space. I suspect they fell down between the radiator and grille and will end up somewhere on rt108 between Ratchet Heads and home, but figured I'd ask.

|

|

|

|

And this is why I live in Virginia. You New Englanders are nuts. Edit: How many Sockingtons of rust was this Ranger?

|

|

|

|

Haha how is that even worth it. Buy a clean ranger for like $2k instead of wasting 48 man-hours on a POS for someone who doesn't respect your work. And it's still a rusty pile with a junkyard motor when you're done.

|

|

|

|

Raluek posted:Haha how is that even worth it. Family. It has some strange bonds man. Mind you they saved kens rear end a few months ago.

|

|

|

|

Raluek posted:Haha how is that even worth it. Buy a clean ranger for like $2k instead of wasting 48 man-hours on a POS for someone who doesn't respect your work. And it's still a rusty pile with a junkyard motor when you're done. Dude don't even get me started. If I had realized this thing was this hosed when I welded the frame back together a few times over the last few years I would have told him to jack up the license plates and roll a new truck under them. Sadly my parents fall fully on the "drive it till it doesn't move, no mechanical sympathy, ignore all warning signs of impending meltdown" side of automotive maintenance. I don't even *hear* about vehicle problems until it has already stopped moving, unless I am lucky. Here's how the Ranger's engine death went: * a long time ago, in a rustbelt far, far away* Ranger starts misfiring and hesitating under load. Dad throws new plugs in, but can't get #1 to come out, so he only replaces 5. Hesitation continues, he says gently caress it and just drives it. P0301 persistent #1 misfire. For many thousands of miles. I show up last fall and proceed to fix everything, or at least try. I note that at the very least he's slagging the cat by dumping unburned fuel through it, and at worst, he's actively burning the motor up. He insists it must just be the spark plugs. We change the spark plugs. No change. He insists it must just be the plug wires. We change the plug wires. No change. He insists it must just be the coil pack. It's waste spark, that would cause two cylinders misfiring. I tell him which brand to buy, and to avoid the gutter trash no name brands. He promptly buys one of the gutter trash brands because it was cheaper and had premium in the name, unlike the well known brand I specified! No change. He drives it to Vermont to go skiing. Halfway there, I get a call. Dad: so the truck started bogging down so bad I couldn't maintain 55 on the highway on hills, oil pressure gauge went crazy, I stopped and it was like 4 quarts low, I know it was full a month ago when I checked it. Something is wrong. Me: alright, call a tow truck, you're coming home on a flatbed, no way it'll make it, lemme start shopping for parts. A motor on rockauto will be 1900 bucks it looks like. Dad: well so I kept going and it was really bogging down. Me: yeah, it's hosed, I told you not to do that, call a tow truck. Dad: oh poo poo now the oil pressure is flaking out again and the CEL is flashing, what should I do?! Me: WHAT THE gently caress, I THOUGHT YOU WERE ALREADY PULLED OVER, YOU'RE STILL DRIVING IT?! Dad: yes. Me: pull. the. gently caress. over. and. call. a. tow. truck. If you put a rod through the side of the block there's a good chance you'll set the drat thing on fire. And yeah they saved my rear end, I'll save theirs. I've set them up with carbot.org, as long as they update the mileage occasionally it will nag them to maintain their poo poo. At least it still drove itself to the shop for its new engine. e: oh yeah. He didn't realize how hosed the thing was until I drove him home Saturday night (since his truck had no engine in it) and he noted that I was accelerating really quickly. In a Forester with a 2.2L super low compression engine in it that probably makes 120hp on a good day, with two 200lb dudes and like 500+ lbs of parts and tools in the back, pushing us probably over the 4400-4500lb mark. I wouldn't be surprised if that 3.0 was down into the double digits. I really can't wait to tear it apart. kastein fucked around with this message at 22:11 on Mar 2, 2015 |

|

|

|

Alright, about to go home and tear the engine apart after we pick the truck up. In the meantime I checked RatchetHead's Facebook page and they posted one of the pictures they asked if they could get. They take better pictures than us.

|

|

|

|

OF COURSE THE loving TAKE ONE WHEN IM TAKING OF MY SWEATSHIRT GOD drat IT

|

|

|

|

Slow is Fast posted:OF COURSE THE loving TAKE ONE WHEN IM TAKING OF MY SWEATSHIRT GOD drat IT Nice belly, dude

|

|

|

|

Kendad sorta looks like Tim Robbins in Antitrust.Slow is Fast posted:OF COURSE THE loving TAKE ONE WHEN IM TAKING OF MY SWEATSHIRT GOD drat IT Just one?

|

|

|

|

At least when I got undressed at adiabatics he didnt take pics. Now I know how hayden panettiere feels

|

|

|

|

Slow is Fast posted:At least when I got undressed at adiabatics he didnt

|

|

|

|

Wait until you have kids. Then take them to the beach with extended family whom then goes picture crazy. At 185 lbs,I have never felt so fat.

|

|

|

|

Slow is Fast posted:OF COURSE THE loving TAKE ONE WHEN IM TAKING OF MY SWEATSHIRT GOD drat IT

|

|

|

|

^ that's what I was thinking STR. Also the exhaust manifold thing isn't exclusive to ford. Chevy also looses them in the same spot just the bottom of the manifold instead of the top.

|

|

|

|

Hate on domestic engines breaking exhaust studs all you want, at least you can get to the bolts. My brother's Jetta has a bolt on the header that has enough clearance for a 1/4" drive 13mm socket to fit on it, but not room for a ratchet or a u-joint extension. The shape of the head also prevents getting a normal wrench in there.

|

|

|

|

Toyota does this poo poo too, except it's even an alloy head and the studs have exposed threads and a nut instead of just a studbolt, and they look like they'd break off in a metric microsecond, which is why I refused to touch them and instead elected to drill through six 10mm hardened studs in the manifold flanges in-place on the vehicle lying in a gravel driveway using an electric handyman's drill when I worked on my uncle's truck. All manufacturers suck at exhaust serviceability. Strangely, chrysler got this right up until the end of the 5.9/5.2 - the head to manifold bolts rot of course, but you never have to touch them, and the manifold to Y-pipe ones are through bolts so cut and forget. The rest is bullshit you can solve with money instead of tears, broken drill bits, and hot shavings of metal falling on your face while you drill futilely into important, expensive parts with important, inexpensive garbage fastener halves stuck in them. EightBit posted:Hate on domestic engines breaking exhaust studs all you want, at least you can get to the bolts. My brother's Jetta has a bolt on the header that has enough clearance for a 1/4" drive 13mm socket to fit on it, but not room for a ratchet or a u-joint extension. The shape of the head also prevents getting a normal wrench in there. whatever dude, it went on easy at the factory, I dunno wtf your problem is.

|

|

|

|

kastein posted:whatever dude, it went on easy at the factory, I dunno wtf your problem is. With some specially built low-profile wrench, I'm assuming.

|

|

|

|

Slow is Fast posted:OF COURSE THE loving TAKE ONE WHEN IM TAKING OF MY SWEATSHIRT GOD drat IT No homegrown Seeing that drain pan... your "CLR and buttmud" description suddenly seems quite accurate.

|

|

|

|

The first draining of the new motor was actually chunky with sludge. Easily the worst cooling system I've ever seen. I'm pretty sure the owner of the donor truck had realized he had a horrible coolant leak and just filled it with tap water every time it got low. Never seen one corroded like that.

|

|

|

|

Would you use CLR for a coolant flush like that again, or would it just be cheaper to throw gallons of vinegar at the problem?

|

|

|

|

|

| # ? May 12, 2024 21:47 |

|

CLR wasn't that much. I paid 23 bucks for a gallon and we used like 3/4 of it. The good thing about it is that it's mostly lactic acid and gluconic acid - the former is good at eating basic (as opposed to acidic, not as opposed to complicated) oxide/hydrate sludges off of things, like calcium buildup and rust, the second is a long-chain organic acid with a hell of a lot of -ol groups and nonpolar sections that make it good at cleaning up oily gunky garbage too. Related chemicals calcium gluconate and sodium glucoheptonate are used as hydrofluoric acid poisoning antidote and one major ingredient of Gunk CC3K Carburetor Cleaner. They're fairly weak acids (they don't dissociate very readily) so they don't eat up your gaskets and block very fast, but they do love cleaning up cooling system residue. I don't think vinegar would do as good a job and would probably do more damage to the engine.

|

|

|