|

ante posted:(Don't use acrylic) You hear that all you people who own and have access to cutting lasers! Don't use acrylic the next time you are using your cutting lasers to make shelves. . . . rear end in a top hat! that is soooo freaking cool! I need details!

|

|

|

|

|

| # ? Apr 28, 2024 07:03 |

|

I've been building different attachments for my CNC machine. Plasma cutter for sheet metal, dremel holder, router holder, etc. Laser cutter is next on my list, but I don't know much about laser options out there. I'm eager to hear about your setup!

|

|

|

|

excidium posted:I'll be posting an in-wall bookshelf I built here in a few days as I clean up some final things, but I am interested in knowing how exactly to get a high quality paint finish. It's just a pretty standard shelf painted white, but man, for the life of me I am unable to get a real quality finish on any project that end up painting. Anyone have any tips on what I can do to improve the finish on things? Or just cheat and use a self-leveling enamel. Something like Sherwin Williams' ProClassic comes out nice and smooth on most surfaces. Do the prep (sand, clean with tack rag, prime you're worried about durability or stains coming through), and throw it on. Just don't load the shelves before it's fully cured. Comes in latex, too, so you don't have to murder your brain cells as much.

|

|

|

|

Fooley posted:This gives me an idea. Assuming proper supervision for the kid, how bad of an idea would it be to do this but with a hot plate and toaster oven in there. Basically a kicked up Easy Bake (with room to stash the cords so they could still play cook). Pretty bad, you build a play kitchen so you DON'T have to watch them constantly while they're playing with it. Mama needs some quiet time, go cook some pretend eggs.

|

|

|

|

Eat the pretend eggs, Lyz.

|

|

|

|

I've got access to my local hackspace's RedSail laser cutter. It's one of the cheap Chinese options, but at like four grand, it's not really that cheap. 80w, 100x80cm bed I think. You don't really want to go less powerful than that. I've used a 40w one a fair amount, and it's good for etching but not much else. The 120w one was pretty amazing, I was cutting 3/8 acrylic and it wasn't even blinking. Basically lasers are awesome and if you're in a large metro area, you probably have a local hackspace that either has a laser cutter or is trying to collect donations to get one RIGHT NOW.

|

|

|

|

Katalox is really dense... up to 600 grit and mineral spirits.

|

|

|

|

excidium posted:I'll be posting an in-wall bookshelf I built here in a few days as I clean up some final things, but I am interested in knowing how exactly to get a high quality paint finish. It's just a pretty standard shelf painted white, but man, for the life of me I am unable to get a real quality finish on any project that end up painting. Anyone have any tips on what I can do to improve the finish on things?  Not perfect but turned out pretty good I think. The shelf extends into a storage room on the other side a bit so that the bottom shelf can fit a printer. It's on a slide out shelf so that I can still access the scanner on top. I have room for one more shelf that I'm going to add but ran out of wood for the moment, so that will be added shortly.

|

|

|

|

Looks good. Looks like you got a nice glossy finish on the shelves.

|

|

|

|

Ante, that's super cool but wood grain under that weight and direction of force will also fail. Why not laser cut steel? Send the design out to a local laser place that does steel, that's a neat idea/design?

|

|

|

|

I don't have the ability to cut steel and I don't want to spend real money on this. I did break a couple of the clips while putting them in, but it's still a lot stronger than acrylic was. Maybe in a month or two, one of the CNCs in my hackspace will be operational. I've been building some acrylic geared stuff, and steel versions would be pretty rad.

|

|

|

|

There are some guys offering a laser cut steel service in SA-Mart.

DethMarine21 fucked around with this message at 21:37 on Jan 16, 2014 |

|

|

|

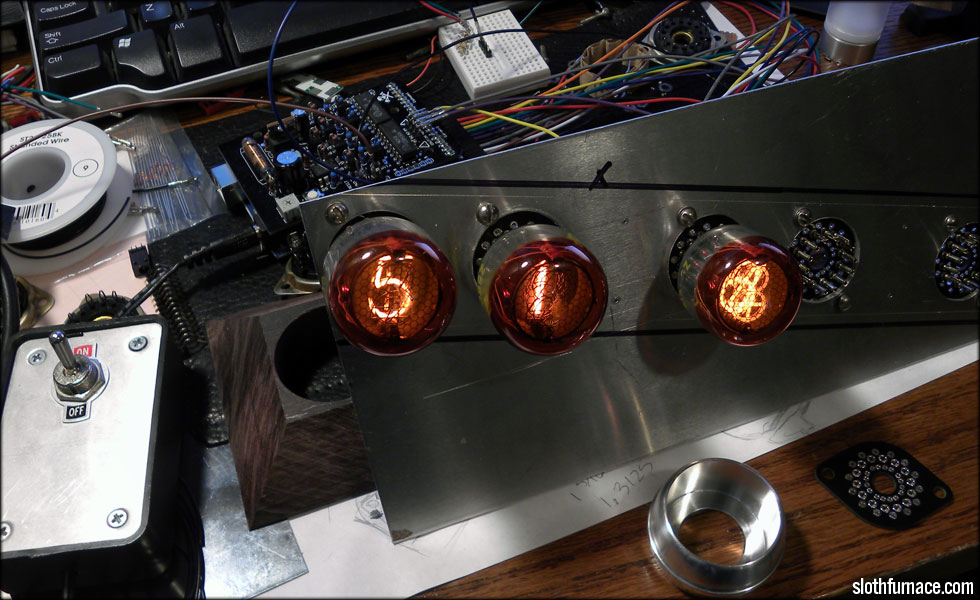

Little nixie clock function test... https://www.youtube.com/watch?v=25EeNTql_Vc

|

|

|

|

nonentity posted:Little nixie clock function test... Simply beautiful

|

|

|

|

The Lightbodge, or, how to make a lightbox in 3 easy steps Öand about 15 million difficult ones. With that obvious joke out of the way, on to the meat of the project. My current light box setup sucks.  And it produces poor results.  As you can see from this illustrative, but poorly illuminated, example. Itís constructed (if thatís the right word) like most, from a hollowed-out cardboard box and some tissue paper. Itís too shallow, and the lights are way, way, WAY too dim. So for a while, Iíve been wanting to replace it. Iíve recently got into hobbyist woodworking, and I thought hey, why not build one? Turns out, itís actually pretty straightforward, though I lack the tools and expertise to do a really *good* job. I based it around these raw materials:  3* Screwfix dirt cheap white circular ceiling light fittings with frosted glass covers. £8.99 each. Simple, easy to install, and no need for any separate covers Ė Iíd initially planned to mount lights outside the box and cover holes in the outside with frosted perspex, but that would have been kind of expensive. A 3-gang dimmer switch. A goon suggested that individually switchable and dimmable lights would make a pretty kicking lightbox Ė I doubt Iíll actually wind up using the facility much, but weíll see. At £16.49, the most expensive component, and probably the least necessary. Some cable, and a plug. Not the ideal cable for the project; Iíd probably have been better off cannibalising a cheapo extension cord, but this does the job. About a tenner from Screwfix, probably way better than I need, but no harm in overbuilding. 12mm Plywood. I got a full sheet of decent quality ply at BuildBase for £20, a 1/3 discount due to some slight discolouration and damage I didnít care about. Again, possibly a bit overengineered, I could have got away with thinner, but itíll do. Again, no harm in overbuilding. Paint. I used Vinyl Silk emulsion. I had it knocking around from painting cupboards. A sheet of white card. £2.99 from Rymanís. A2 size, I think itís intended as backing board for picture frames. Nuts, bolts and screws of various sorts. About a fiver for the lot, but I only used a little from each packet. Some odds and ends of cutoffs from other projects Ė more on that story later. Duct tape, naturally. Total cost of about £70, but in that I got a bunch of bits and pieces spare to use in later projects, in particular the plywood. I initially planned, as you can just about see from the image above, an elegant, perfectly cut finger jointed box. I set out to do this withÖ a jigsaw. It was unsuccessful. I managed to make a box, but it was not elegant, and the joints were way too gappy to even consider gluing it up properly, so for the first time of many on this project, I said to myself ďgently caress it, BOOODGE!Ē. So I put spare offcut blocks in the corners and screwed the thing into those. It holds together reasonably well, but I wouldnít trust it with much actual weight. I may, at some point, pull it apart and put it back together with some gapfilling adhesive of some kind (PU construction glue probably), but for now, itíll do.  Then, I drilled the holes to fit the light fittings, and added the switching gear , again, with a fairly huge bodge, of screwing it onto some wooden rails screwed on to the back from the inside. I painted the inside with 4 coats of vinyl silk emulsion, the first (and second, third and fourth, because I had a tonne of spare paint) one being thinned down 4 parts paint to 1 with water. It took a bit of covering due to the dark plywood.  I added the sheet of card. Handily, at this point one of my bodges came good, because the blocks I added to screw the whole thing together, conveniently allows me to slot the card in behind them without needing to tape or glue it down. Useful. I added the light fittings. These are bolted on, to save me adding yet more thickness to the outside, or using tiny screws which risked not holding.  I wired the whole thing up. Most worrying part, as I am no electrician.  Finally, add bulbs, covers, and switch it all on with distinct trepidation. And after trying it outÖ It didnít burn down my house, and it all switched on, which is gratifying. I must have been loving channeling GCSE physics.  How do the photos look?    Better, as you can see. Not having to use the flash means I can control the white balance better. But it still needs some brightening. Itís improved very slightly by adding two of the desk lamps from the original setup in front of the box (righthand end). Slightly more pop on the brights this way. But the real trick to this is that I worked out that what I need is a new camera on which I can control the exposure time and f stop without switching to night scene mode which doesnít play well with the macro setting. That would really help. Evidently, a good carpenter I am not, but this was fun and satisfying, and surprisingly successful given that the only applicable power tools were a jigsaw, a combi drill and an impact driver. E: tables, sorry thespaceinvader fucked around with this message at 22:48 on Jan 17, 2014 |

|

|

|

I know it's ugly as heck, but I made a cargo sled last night! Needed a way to get groceries home on my bike, and here we are.

|

|

|

|

You're riding a bike in conditions where a sled is more appropriate than a wheeled cart? Bravo.

|

|

|

|

Hahaha, that thing is ghetto as gently caress. I love it.

|

|

|

|

|

Gullous posted:It was roughly 6 months of my life, putting in between 10 and 40 hours a week on top of my full time job. My mom ended up spending $27k on materials and other labor. We're looking at $292k - the realtor said we'd be lucky to get $160k without any work. This was a cool post to see the transformation from start to finish. Really impressive! It's a shame though about how it didn't get done until it was too late to enjoy living in it. My parents lived in a house for 8 years before putting in beautiful landscaping 2 months before we sold it, for the same reasons.

|

|

|

|

Bad Munki posted:Hahaha, that thing is ghetto as gently caress. I love it. That should the the title of this thread

|

|

|

|

So an update on my loom project! I got the heddle system setup and I finally started weaving! I'm using a weave pattern that I made with some weave drafting software.

|

|

|

|

Im That One Guy posted:So an update on my loom project! I got the heddle system setup and I finally started weaving! Do you have a video of thing weaving?

|

|

|

|

ReptileChillock posted:I know it's ugly as heck, but I made a cargo sled last night! Needed a way to get groceries home on my bike, and here we are. This is a thing of beauty.

|

|

|

|

My set of drawers is almost finished. I have to install a shim behind one of the drawerfronts, a little bit of finetuning on the drawer depth rails, and a few coats of clear coat poly on top. Should come out alright!;

|

|

|

|

nonentity posted:Little nixie clock function test... Do nixie tubes have to have those steel rings around them? It seems like it would reduce the viewing angles unnecessarily.

|

|

|

|

~Coxy posted:Do nixie tubes have to have those steel rings around them? It seems like it would reduce the viewing angles unnecessarily. No, nixie tubes look are packaged pretty much like any other glass vacuum tube:

|

|

|

|

Motronic posted:No, nixie tubes look are packaged pretty much like any other glass vacuum tube: Not exactly, some are side view, some are end view. The end view ones I use in my clocks don't have to have the aluminum bezels I put around them, those are an artistic addition.  They don't impact the viewing angle at all. nonentity fucked around with this message at 19:44 on Jan 22, 2014 |

|

|

|

nonentity posted:Not exactly, some are side view, some are end view. WOAH! That's cool. I've never seen an end view one before.

|

|

|

|

ante posted:I've got access to my local hackspace's RedSail laser cutter. It's one of the cheap Chinese options, but at like four grand, it's not really that cheap. I really want to get into using lasers to cut patterns into sheet latex, but I don't even know where to start.

|

|

|

|

Start with looking up local hackspaces if you're in a largish city. Otherwise, services like Ponoko will cut stuff for you, but they're a little expensive and you'll probably gently caress it up the first time if you've never used lasers before. Last year sometime, I designed a machine that needed it, submitted it to them, and it came back like $140. I said gently caress that and shelved the project. When I eventually got hands-on access, yeah, nothing really worked right or fit at first. Six months in, I'm only really starting to be able to cut most of my stuff right the first time. So yeah, if you don't have anything locally, I don't know what to tell you. If you can swing it, I think you can buy and build sub-$1000 40w kits that will definitely get you started. It'll take a while to outgrow that if you've never tasted something more powerful.

|

|

|

|

There is a local hackspace, and I have a friend who knows a guy that knows how to run it. So mostly I just need to figure out from him what's required, and also figure out or experiment with power settings to cut the latex, since it's really thin (less than half a millimeter).

|

|

|

|

FISHMANPET posted:I really want to get into using lasers to cut patterns into sheet latex, but I don't even know where to start. I've used the laser at my hackerspace, but never for latex. I think it should be fine as long as there's no chlorine in it. Find out what formats the laser can take and the bed size. The one at my hackerspace takes svg, pdf/ps, coreldraw and others. It is installed as a printer driver, so it works with a lot of formats really. Then just make vector line drawings for the shapes you wanna cut out. It probably depends on the drivers but our laser cutter is designed to cut based on a few main colors like black(0,0,0), red (255,0,0), green(0,255,0), blue, and a few other similar colors. You can assign different powers/speeds to each color which you configure before you print. So you can probably do it all in one color if you'r not trying to engrave an image on the surface or anything besides just cutting straight through.

|

|

|

|

peepsalot posted:I've used the laser at my hackerspace, but never for latex. I think it should be fine as long as there's no chlorine in it. Speaking of lasers...  I just got this back from the laser etcher. Turned out nice!

|

|

|

|

I'm in the early planning phases of turning my framed wall shed into a multi-purpose garden shed/chicken coop. I'd like to also take this as an opportunity to install solar power since electric isn't run out there, and I think it'd be fun to have for lights, chicken care, and novelty. I'd like it to be a 'smart' system. I want to integrate the energy readings from the panels, batteries, etc into a networked solution (preference being controllers I can run ethernet cables to a wireless hub in the shed). I've done precursory searches on things like this and I'm not coming up with much other than industrial things. I would have figured this stuff had entered the low-use hobby community by now, but I might just be missing it. Would anyone have suggestions or recommendations? Big Beef City fucked around with this message at 02:51 on Jan 24, 2014 |

|

|

|

Big Beef City posted:I'm in the early planning phases of turning my framed wall shed into a multi-purpose garden shed/chicken coop. It might be a little overkill but the OpenEnergyMonitor system is pretty neat: http://openenergymonitor.org/emon/guide I have a kit in my workshop waiting to be assembled and installed.

|

|

|

|

Inspired by nonentity I got some nixie tubes. No clue how to power them and I'm not sure what to use them for (perhaps a vacuum amp with nixie tubes displaying the level)

|

|

|

|

nonentity posted:Speaking of lasers... Very nice. Looks pro. What etching service did you use?

|

|

|

|

Just finished the crib I've been building for our son. Still working on the toddler bed rail and full-sized bed rails, but we've got time to finish those. I'm pretty happy with how it came out, but of course I can't help but stare at the mistakes I made along the way.

|

|

|

|

I made my own extension cords for fun. Got tired of the lovely ones at the local box stores.

|

|

|

|

|

| # ? Apr 28, 2024 07:03 |

|

the spyder posted:I made my own extension cords for fun. Got tired of the lovely ones at the local box stores. What is lovely about the local box store ones?

|

|

|