|

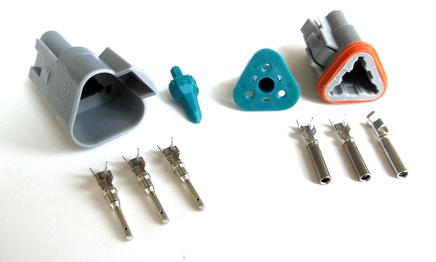

I am a big fan Deutsch DT / DTM connectors. Mostly because of the way the three contact ones look. I am a sucker for triangles.

|

|

|

|

|

| # ¿ Apr 28, 2024 19:37 |

|

http://www.amazon.com/Martin-PL1465K-Piece-Plier-Plastic/dp/B004JN0S3I These snap ring pliers are so cool, but there is no way I paid 100 dollars for those, I think it was more like 60.

|

|

|

|

the spyder posted:I used the numbered set mainly for the last three years (when tapping) and it held up. I broke one bit and resharpened it. It's been worth what I paid. Too bad half of the larger bits look like bananas.

|

|

|

|

These are pretty loving rad for the most part: http://www.amazon.com/Wera-SPKL-Two-Component-Storage-9-Pieces/dp/B000XIUMKC Last time I checked, they didn't make t handle or socket drivers using this profile, which is a shame since it works a bit better as long as you never get it tilted wrong in the hex. If you do, it sucks just as bad as any other allen key. Edit: I guess they do still have hex plus in straight bits of assorted hex shanks. These were listed under hand impact drivers: http://www-de.wera.de/product_detail.html?L=0&file=schlagdreher_und_schonhaemmer_serie_schlagdreher_90_nm_840_2_s&lang=de Commodore_64 fucked around with this message at 07:25 on May 7, 2014 |

|

|

|

Black88GTA posted:Flare tool chat: I didn't think to check this thread before placing an order for a flaring set, and of course I think of it after I've already ordered it. I have that one, and first time I used the drat thing it broke. I turned the tool body down over the die block, snugged it up nice and tight, and it stripped the drat threads right off of that die block at what felt to be a perfectly reasonable torque. I was not too happy about that. Edit: They don't sell parts individually, as well. Didn't even offer to send me a fresh one.

|

|

|

|

Has anyone here tried the nut style vice grips like these :http://www.amazon.com/Tools-VISE-GRIP-Original-Locking-Wrench/dp/B00004SBBE ? Supposedly they work rad on stuck flare nuts, of which my old Corvair has a quite few.

|

|

|

|

kmcormick9 posted:Maybe posting a picture of this setup will help because this doesn't seem right and threadlocker won't prevent screws from breaking A properly designed joint actually transfers a large amount of the load from the fastener to the clamped materials, as long as it maintains a certain clamp load. If it gets loose, all of a sudden all of the force is carried by the fastener instead of the joint, making it more likely to break. Or so I understand it.

|

|

|

|

the spyder posted:Thread restoration: http://www.sears.com/craftsman-48-pc-sae-metric-thread-restorer-kit/p-00942275000P Is that craftsman one a rebadge for the Kastar kit? It's like 20 bux cheaper.

|

|

|

|

kastein posted:I'm reasonably certain with proper cable used (SJOOW or SOOW, please) and proper strain relief (a rubber gland style cable clamp NOT under tension, with the cable supported by one of these cable support grips) what you describe would be perfectly legal. Yes, I find these sorts of grips extremely pleasing for some strange reason. http://www.automationdirect.com/adc...in_Relief_Grips

|

|

|

|

EKDS5k posted:Does anyone know of a good tool for removing insulation from multiple wire cables, without damaging the insulation on the individual wires inside? I fix a lot of extension cords and charging cables (and the occasional 7-wire trailer harness), and my current strategy of being reeeeaally careful with a utility knife just isn't doing it for me anymore. If you are only using it on cable, I'd recommend something like this: http://www.amazon.com/Platinum-Tools-15010-Cyclops-Stripper/dp/B000BY8BY2/ref=sr_1_33?ie=UTF8&qid=1426176802&sr=8-33&keywords=cable+stripper Bonus version I've never used but always wanted to try option. http://www.amazon.com/Greenlee-Comm...=cable+stripper http://www.amazon.com/Ideal-Industr...=cable+stripper They also make ones similar to the first, but with a bulkier design and better blade guide, but I can't seem to find a good example.

|

|

|

|

One cool thing a lathe can make is bead roller dies. I've seen a guy make a form tool from a piece of steel plate, grind a cutting relief, and just jam it into the rod. You use the cutoff from the plate to cut the mating roller. Bam, instant crazy profile on your sheet metal. Edit: Formatting is all hosed, but this is the just of it! http://www.jalopyjournal.com/forum/threads/tech-week-few-bead-roller-ideas.679104/ Commodore_64 fucked around with this message at 23:11 on Apr 21, 2015 |

|

|

|

Got my pops a big set of ratcheting wrenches for his birthday so he can work on his olde scout that is sitting in our barn right now (along with his other metric using vehicles). I was really thinking of getting two of the master series gearwrench kits, but this one came with stubbies and I was a bit too curious about them. http://www.amazon.com/gp/product/B00ADXMWGO/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1

|

|

|

|

Sadi posted:EDIT: Oh and this little guy followed me home. He hasnt been very helpful around the garage though. I think your catte is defective. Even looks weird.

|

|

|

|

Safety Dance posted:A swivel head ratchet is what you want. E.g. http://www.amazon.com/TEKTON-1491-Quick-Release-Ratchet-72-Tooth/dp/B00A50NB1K You could go full stupid and get a http://www.amazon.com/Wera-Zyklop-4-inch-Drive-Ratchet/dp/B001V9NCS6/ref=sr_1_28?s=hi&ie=UTF8&qid=1443207426&sr=1-28&keywords=zyklops

|

|

|

|

Mercury Ballistic posted:Pictures to follow, but I just found a $20 power hacksaw. Brand is Keller, motor turns and it seems to cycle as designed. It is on a homemade cart as it weighs about 200 lbs. Is it worth anything? I dont have any need, but at $20 why not? It looks circa 1950s to 1970s. Lots of cast iron. I love it and I am jealous forever. It is roughly like a horizontal bandsaw but much slower. Set up right I hear it has some certain advantages. Find me a metal shaper next!

|

|

|

|

http://www.amazon.com/Teledyne-Ther...l+wire+stripper I know stripper chat has died down, but I've always pined over one of these. Maybe an Ebay special will do me. I hear you must be careful with the temperature around Teflon insulation, maybe even with Tefzel/ETFE. Heck, I wouldn't mind a wire striper of some sort, it would make rebuilding ancient wiring harnesses much more cost effective.

|

|

|

|

Ebay some old Lufkins or Mitutoyo, that's what I did, at least. Edit: Bore gauges are a bit pricier, though. I got a Mitutoyo model and it served me pretty well. The kind with the little wheels and a plunger. Make sure to get one that has anvils for the range you intend to measure, also make sure to get an appropriately sized micrometer to set it with, as error increases the further you get from 0 so guessing really isn't helpful. Also make sure to get a standard to set that micrometer with, and finally make sure that everything is at the same temperature when you set and measure. Measuring in the tenths range is pretty involved! Commodore_64 fucked around with this message at 05:01 on Nov 23, 2015 |

|

|

|

Motronic posted:If you're going to eBay either of those you may as well just skip the bullshit and get these: http://www.amazon.com/Neiko-01407A-Electronic-Digital-Extra-Large/dp/B000GSLKIW/ref=sr_1_1?ie=UTF8&qid=1448293875&sr=8-1&keywords=micrometer Apart from calipers, I prefer to avoid digital readouts on these sorts of measuring instruments. Mechanical portions still wear out, but you don't have to deal with having an irreparable lump after a button cell looses its contents. That and ordinary micrometers are very inexpensive. Some digital indicators or micrometers have really neat features, like setting up a pseudo analog scale with your tolerance limit marked on it, reversed reading, recorded min/max etc. And digital outputs. But mine are for me measuring a one off part or crankshaft, not for 5000+ measurements of the same dimension.

|

|

|

|

Man, that Pelican Case tool box at the bottom of the page looks AWESOME.

|

|

|

|

I have a 9x20 I got years ago before my brother and I got a mostly functional 14" rockwell. The belt drve sucks haaaaaaaaaaard. Needs a total redo the moment you get the thing. Also the tailstock was .040 too low. Still, it's fixed more parts than I can count. Get a quick change toolpost asap. Also look into a new hold down for the cross slide. Also also replace all of the socket head cap screws with real fasteners, most of them are flimsy as cheese. The stock setup is so loose and not rigid that the cutter can dig in and stall the thing. More chucks are also more fun.

|

|

|

|

mekilljoydammit posted:Unrelated to prior post, but going back through the thread it seems like there's some people pretty knowledgeable about wiring stuff. I'm looking at stepping up the grade of stuff I'm doing in race car wiring harnesses - to a degree that may be complete overkill but whatever. It looks to me like the Daniels AF8 with the TH163 turret head will do Deutsch DTM and AS connectors (at least #16 and #20, which is what I'm mostly concerned with anyway) and the TH1A head will do the MIL-DTL-26482 stuff. Am I on the right track, and are ebayed crimpers/turrets likely to be good enough? I've used these guys before, their used ones are checked out and meet spec. Ebay ones could be totally worn out and you might never know except for the poor pull out of the crimps you make. http://store.crimptools.com/26-daniels-crimping-tools-

|

|

|

|

mekilljoydammit posted:Ooh, and they have surplus connectors too, thank you for that. Check out the resetable circuit breakers: http://store.crimptools.com/90-circuit-breakers-mil-spec-aviation-quality- Also, try here for wire: http://www.skycraftsurplus.com/shieldedmil-spec.aspx

|

|

|

|

um excuse me posted:The lease is for a year. The work I moved there for is a 2 year contract position and could become permanent. If all you have is a loaded box and a drill driver set, find some cabinets or an attic to put them in. Ditch the box and live a happy life full of nice tools. Get smaller boxes to store the stuff in out of the way. Hell, put in french cleats on a wall in an unoccupied room and hang all your stuff! Just plaster over the screw holes for the backing board for your cleats and give it a slap with the paint brush, lol.

|

|

|

|

Ferremit posted:Ive also heard good things bout AEG gear too. Welp, something is deflecting. The main tube looks to be pinned at the based, and its unlikely that the tube the spinning part goes in is bending down. That leaves the flywheel adapter part, the little triangulation straps, and the front legs. See what's deflecting and add more of it! The front legs could get some vertical stiffeners to keep them bending. The straps could be replaced with square tube. The flywheel adapter's tube thickness is somewhat limited, but you could beef up the arms that go out to the different holes, or reinforce the plate that has the tube welded to it.

|

|

|

|

Mcqueen posted:No. New cordless tools have auto cut offs when they draw too much power. Doesn't matter what size batt you use as long as it's working correctly. If they have 2 way communication, they would know what capacity battery is being used. The higher amp hour one should probably allow for more current, whether because 10*C on the larger cells is a higher number, or because there are more cells in parallel.

|

|

|

|

My brother the spyder talked me into yet another tool deal, bought one of these for my new house. https://www.amazon.com/gp/product/B004AH1IIM/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 185 bux really ain't bad for a USA made 6.5" vise!

|

|

|

|

For a while there were some PB Swiss tools listed on Amazon under cosmetics. I got some gold plated screwdriver sets, hex drivers, and some bottle openers for something like 60% off, as I understand it there were category based discounts assigned by robot. Should have bought more.

|

|

|

|

I like Precision Instruments stuff a little better, but they are comparable to CDI in price and quality.

|

|

|

|

Anyone have any suggestions for CV joint banding tools? I've got some booting to do on my Sbubaru.

|

|

|

|

stevobob posted:On soldering chat, I have a couple of crappy soldering irons here at home but at work I regularly use a Pace PRC-2000 and it makes soldering easy. Equipment absolutely makes a difference, It also has hot air, extraction, tweezers, interchangable tips, three individually adjustable heat channels and a ton of other poo poo I've never played with. Spend the money, it's worth it. Best I can figure it's like welding, you can weld with a $200 Princess Auto/Harbor Freight welder but if you spend more you'll have a much easier time making much higher quality work. I am going to jump on the Pace bandwagon, too. The ADS-200 is really good for the price, for $250 you can pick up the station and a few tips. https://www.tequipment.net/Pace/ADS200-8007-0578/Soldering-Stations/?OrderItemId=5438829 Mostly I love the 120W monster tips, like this 1/4" inch chisel. I think they also have a 3/8. https://www.tequipment.net/Pace/1131-0055-P1/Tips/?rrec=true And for finer stuff, it can run much smaller tips, but they have a smaller heater. Small is still like 67W https://www.tequipment.net/Pace/1130-0003-P1/Tips/?b=y&v=126323 I also have some of the hoof looking wave solder tips, but I haven't really used them.

|

|

|

|

GnarlyCharlie4u posted:I did a thing. Yesssssssssssssssssssssssssssssssssssssssssss! I seriously love this thing. Not very Automotive, but my Famicoms have put this thing to good use so far. The price of a Haako, but things from Pace seem to have 10-15 years of replacement / compatible new parts instead of 3-4.

|

|

|

|

If your jack has suitable holes in the lifting surface, you could weld a plate to some square tubing and bolt it to the jack. Just guessing.

|

|

|

|

I have some of these Iíve been meaning to install on an old cabinet saw. Seem like a good choice. https://youtu.be/5aCMIsfmiVk

|

|

|

|

Big Dick Cheney posted:I use the microjig splitter kit with a zero clearance insert. The inserts are pretty easy to make with plywood/phenolic. Make a couple of different ones to account for blade height, if you are worried about the distance between the blade and the splitter (and I was) They looked pretty easy to install, just a few holes to drill in the blade insert, comes with a jig. Do you have to drill the phenolic inserts twice or something?

|

|

|

|

KYOON GRIFFEY JR posted:thanks yall, I was trying to spend less money if possible though! No sorry, I am going to dogpile here. I have had many flavors of Hakko over the years, and that Pace is NICE. The tip selection alone makes it worthwhile. The handpiece is way nicer than the similarly priced Metcal unit, and that tip to finger distance really pays off. That being said, if you are using it to solder say wire splices and not pcb components please disregard all the fanboyism.

|

|

|

|

powderific posted:Tangential to soldering irons, does anyone have a recommendation for a third hand kinda thing? For years I had a really garbage one from Radio Shack that was almost as much of a hinderance as a help, but now that it's gone something that works well would be nice. I got one of these things. They are ALMOST not poo poo.  https://www.amazon.com/gp/product/B072KKWCP1/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1 All the little arms are magnetic, which IS really nice for under dash or working on projects in odd places. At work I have a steel hutch on the bench that I can mount a couple to. Hold wires, cables, whatever weird thing. Not the greatest for soldering as the goosenecks tend to spring back, so they are fiddly to get set in the right place. Awesome for say holding a lead soldered to the leg of some mystery component so that your test leads don't drag it away. If I got really into it, I think I'd like to adapt some of these to have little grabbers / clamps where the indicator mounts. Especially with the wonderful fine adjustment mechanism.

|

|

|

|

monsterzero posted:That looks a lot like my sick rear end Dakine snowboard tool: I would probably hate actually using this, but drat that looks so cool!

|

|

|

|

Possibly a bad start cap? Takes too long to start and gets the breaker that way? Seconding bad breaker after that.

|

|

|

|

I love tools like this that I actually pick up 5 years later and go "wait, this thing is actually useful!?" It makes me feel better about my poor life choices in excessive tool buying.

|

|

|

|

|

| # ¿ Apr 28, 2024 19:37 |

|

RE: transmission jacks The car lift/hoist combined with a hydraulic lift table and wood cribbing is super versatile.

|

|

|