|

Hubis posted:You could always do an Etsy shop -- only list the stock you've got with little commitment to make it a constant product supply. drat, that's a good idea. I'll mention it to him, once upon a time he made guitars and has a company he may be able to reactivate. I'll keep you posted on how that develops.

|

|

|

|

|

| # ? Apr 28, 2024 21:27 |

|

I am varnishing some projects with the same varnish I've always used (not poly) and its drying a bit cloudy in areas. Not spotted just sort of a haze over some spots. Its gotten a lot more humid lately so I'm guessing thats the cause, will this fade if I move the piece to a dryer area and let it cure more or am I busting out the sander again?

|

|

|

|

Sylink posted:I am varnishing some projects with the same varnish I've always used (not poly) and its drying a bit cloudy in areas. Not spotted just sort of a haze over some spots. Take a hair dryer or heat gun to it gently and see if it clears

|

|

|

|

Jadus posted:If you wouldn't mind I'd appreciate it. Here you go, 1 box = 2", sorry about the stains, my bench doubles as a homebrew station and that got caught in the crossfire. Let me know if you need any more photos of anything specific and I'll snap a couple.

Meow Meow Meow fucked around with this message at 01:46 on Sep 23, 2015 |

|

|

|

I made a small solar collector that I started on last friday. Started with the frame for the window, as I would size the rest of the collector after that: Then the frame, surplus paneling from the house & garage build.  Insulation that was left over, I will add more in the back of the collector to insulate against the wall:  Assembled and mounted on the wall. I have painted the inside matte black. The outlet and inlet are in the lower left and upper right corners respectively. I've not installed a fan yet. I will take the air from the upper part and suck it below to achieve a better mixing of the air in the collector and shop. The fan is rated to be able to replace all the air in the shop around 3 times per hour. You want a high throughput of air, the goal is not make the solar collector as warm as possible.  The window frame is attached with hinges and locks, also added weather stripping to seal it up. I still need to seal up the frame against the wall too. There is a sub frame with a mesh inside the collector that the air will pass through.

|

|

|

|

Neat! I've never seen one of those in use up here, will it be effective come December/The Darkness?

|

|

|

|

Probably not, but it'll help out between aug-oct and feb-april.

|

|

|

|

First time I have ever seen a Stanley 55 with what appears to be a complete set of accessories/blades - http://detroit.craigslist.org/okl/tld/5211950672.html If only I had $500 to drop on it

|

|

|

|

I like it when my tools have bad puns on them. (I used it for sticking though)

|

|

|

|

Ugh, I was sick on sunday so didn't jump on it and now I'm regretting it. A pretty nice 14" delta clone band saw (Rex Cut from Busy Bee Tools in Canada) was up on craigslist for $75. Those kinds of saws are usually $175-300 here. Oh well, as a guy at work says, there's always another deal on craigslist. Also got a Lee Valley tools gift card from my wife for my birthday. Gonna pick me up one of those fancy router planes since used ones never ever seem to show up around here. Used hand planes come up pretty regularly but I don't think I've seen a router plane ever in many months of avid used tool watching.

|

|

|

|

My table lives! It's my second large handtool-only project, and is loosely based on a design for a Roubo workbench, but given that it's made to hold a microwave, much smaller. The top is two face-glued 18mm pine lamboard pieces. The legs and strechers are all standard homecenter pine. The stretchers and legs are jointed with drawbored mortise and tenons, and the top is held on by through-tenons. I finished the table with three coats of tung oil, and am weighing whether or not to add a beeswax finish to the top. It is a piney little tank of a table.  There are a few mistakes that I've either fixed or learned to live with. I set one pair of through-mortises too close to the tabletop edge, and an endgrain blow out resulted. I fixed it with another piece of pine and some glue. It was more of a cosmetic issue than any structural concern. I also should have done more of the sanding and finishing prior to assembly. I had started with the mortises by using a forstner bit in a brace, then cleaning up with a chisel, but it always felt that the fitting process was inefficient and haphazard. I switched for the final 10 mortises to only a bench chisel, and was a lot happier with the results, near perfect fitting right off the bat, just unhappy downstairs neighbors.

|

|

|

|

Does anyone here work in the trade? I'm starting to buy some serious machines and I'd like to bounce ideas off of someone.

|

|

|

|

E: double post

Silver Nitrate fucked around with this message at 06:12 on Sep 25, 2015 |

|

|

|

Does anyone here work in the trade? I'm starting to buy some serious machines and I'd like to bounce ideas off of someone. I'm legitimately jealous of some of the stuff you've been doing, I wish I could go to Actual School for this stuff.

|

|

|

|

|

Just do it! Trade school isn't very expensive and chances are you have a decent program by you.  I have three main dilemmas. First, I want a sliding table saw so hard. But they are very expensive and take up a LOT of space. But I probably need one if I'm going to be doing any volume of sheet goods or I could get a panel saw but they kind of suck and I'm 5 times faster on a slider. Panel saws are also a lot cheaper. I also want a CNC, but I need a good way to handle sheet stock before it gets to the machine so that is not a priority right now. Second, a jointer. I loving hate jointers but there are things only a jointer can do. And since I cannot afford an inline rip saw if I blow all my money on an Altendorf F-45, it's kind of required. Third, a nice radial arm saw or a big sliding miter saw? I'm thinking radial because they can do many cool things, but then I would need a very large bench for it. Stuff I already have or am definitely getting: wide belt sander, planer, saw stop, domino machine, pocket screw machine, drill press, band saw, small miter saw, two shapers, and a gently caress load of hand held power tools.

|

|

|

Silver Nitrate posted:I also want a CNC, but I need a good way to handle sheet stock before it gets to the machine so that is not a priority right now. No no, the solution here is to get/build a CNC rig big enough to handle raw sheet goods, so like 9x5. Better make it 10x6 in case you accidentally get some canadian plywood in there.

|

|

|

|

|

lol like I can lift a 10x6. Seriously though, that would be sweet, but I'd still need a panel saw/sliding table saw to do other things with. It would be a pain in the butt to have to program every time I wanted to cut a big sheet accurately. Edit: I guess a vertical panel saw + an inline rip saw would take care of most of the things I need to do. Right now I'm doing everything on the table saw and as good as I am at it, it's pretty hard to cut big, heavy sheets consistently perfect on. Silver Nitrate fucked around with this message at 17:48 on Sep 25, 2015 |

|

|

|

I'm not in the trade, but I don't see many reasons to buy a panel saw over a track saw. I'm planning to make a desk, using a solid surface/acrylic counter top for the main surface of the desk. I'd like to edge at least one side of it with wood; what is a good way to get the surface of the countertop and wood completely flush? Will the solid surface take a hand plane well?

|

|

|

Silver Nitrate posted:lol like I can lift a 10x6. See, now you just add "gantry crane" to your list of things to install in the shop. I would have thought you understood how this worked by now! Zhentar posted:I'm not in the trade, but I don't see many reasons to buy a panel saw over a track saw.

|

|

|

|

|

Silver Nitrate posted:

F45 Altendorf

|

|

|

|

That reminds me I saw an old Altendorf F90 in Sweden recently for 9500kr which is 1000 euros or so. Not sure the exact size in relation to that saw, looks huge though.

|

|

|

|

Zhentar posted:I'm not in the trade, but I don't see many reasons to buy a panel saw over a track saw. attach the wood 1/32" proud and use a router flush cutter. Solid surface like corian and that stuff, I would never dream of taking a hand plane well to it.

|

|

|

|

Silver Nitrate posted:Just do it! Trade school isn't very expensive and chances are you have a decent program by you. What are you going to be building production-wise that insists on a sliding table saw over a standard table saw? Also, why the jointer hate, they are cool and useful.

|

|

|

|

Cabinets. And I've been spoiled by using inline ripsaws and sliding table saws so I'm really not that skilled with a jointer. I use it probably once a month for a really weird thing and that's it. Used f-45s are ~25k. They are amazing, plus the scoring blade is really handy.Zhentar posted:I'm not in the trade, but I don't see many reasons to buy a panel saw over a track saw. Solid surface is a bitch and a half to work with. I would have the solid surface slightly lower than the wood to begin with then remove wood until it is flush. You're going to need buffing pads and compound to get the scratches off of the plastic but making solid surface thinner is terrible and you really don't want to do it. Silver Nitrate fucked around with this message at 19:57 on Sep 25, 2015 |

|

|

|

Bad Munki posted:No no, the solution here is to get/build a CNC rig big enough to handle raw sheet goods, so like 9x5. Better make it 10x6 in case you accidentally get some canadian plywood in there. http://makezine.com/2015/09/24/printrbot-crawlbot-review/

|

|

|

|

That's really cool. Limited in some major ways, but definitely ingenious for a lot of tasks. I dig it.

|

|

|

|

|

Decided to try dovetails for the first time, and not having a dovetail saw figured 'eh, my coping saw will probably work fine'. It did not. I get that it is a hard to quantify question, but will a cheap dovetail saw give me better results, or is the fault more likely in the user than the saw?

|

|

|

Slugworth posted:Decided to try dovetails for the first time, and not having a dovetail saw figured 'eh, my coping saw will probably work fine'. I'm pretty new to dovetails and started out using my coping saw as well. I still use it for some parts but I bought a $30 douzuki off Amazon and it is much nicer for making most of the cuts. With practice I think you could probably do dovetails well with anything but having a good tool helps a lot. I think you could see some benefit from the saw, I did.

|

|

|

|

|

You could do it with a cheapo tenon saw, but spending a little more will get you a nice, thin, Japanese pullsaw which will do a better job without breaking the bank. Something like this http://www.workshopheaven.com/tools/Gyokucho-303-Tatebiki-Rip-Dovetail-Dozuki-240mm.html#SID=41

|

|

|

|

I've just bought some pine lumber for a pair of nightstands, and am planning to let it hang out in my apartment to come to some sort of moisture equilibrium. At the moment I'm just storing the boards under my bed, but would it make sense to crosscut them to a slightly oversize length for storage?

|

|

|

|

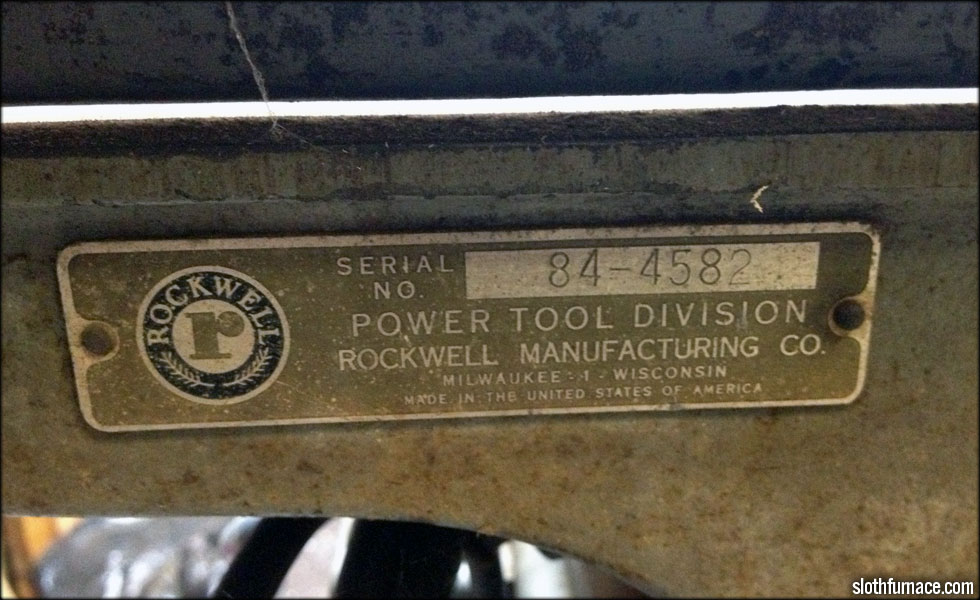

Hey guys, I recently acquired this jointer from my late grandfather's shop.      Now, I have a limited amount of woodworking tools, as I am mainly a machinist. But I do make the occasional box for my nixie clocks...     I don't know the first thing about a jointer, but I assume it would be handy for making these boxes? My boxes are generally 3"x4"x12" or 3"x4"x shorter. I usually in the past have just tilted my woefully inaccurate tablesaw to 45 degrees for all my corners, and sanded to square it up, but I also now have a bosch router and router table with a 45 degree bit that makes that job a LOT easier. However, should I try and get this jointer going for squaring up my boards? Is it even worth messing with? It runs ok, but I think the blades might need changing out. I have no idea how old it is or where to even start with it.

|

|

|

|

Woodworking machines are fairly simple as a rule and most of the consumables like blades and bearings are commonly available. Being a Delta, parts should be no issue though you'd probably have to buy them second hand. Most likely the jointer just needs the tables aligned, cleaning, and blade sharpening; an afternoon's worth of work. Jointers are used for making faces flat, adjoining edges perpendicular, and tapering. Jointing is the second step in milling rough stock (after cutting to rough length). Some people don't like them but I believe they are a good tool to own. It has a Rockwell/Delta plate on the back but on the front center that looks like a Delta Milwaukee logo.

|

|

|

|

The Woodwright's Shop new season has started! I almost missed it because the episodes aren't marked as new on DISH guide.

|

|

|

|

Hey dudes. I'm looking to build a desk top for a kee klamp kit. 72x30x1.5. This will be my first glue up of any kind, I'll be buying pipe clamps soon. I have access to a 51" wide belt sander at work to plane the lumber before and after. I'm stuck at choosing the wood. Is this a project for maple or might there be something kiln dried that will look good with a stain at home depot? My budget for the top is $250. I've never purchased hardwood before, so I'm not really sure how much that would run me. If I went that route, I'd have the hardwood shop rip and plane it for me. Google Butt fucked around with this message at 09:31 on Sep 28, 2015 |

|

|

|

|

Try and find a not home depot lumber yard. You will litrally pay double for the wood over anyone else. Even my local not hardwood mill lumber yard is 1/2 the home Depot for s4s (surfaced on 4 sides) hardwood. If you have a hardwood mill you can pro able to go cheaper than that.

|

|

|

tater_salad posted:Try and find a not home depot lumber yard. You will litrally pay double for the wood over anyone else. I know hard wood comes in irregular sizes, probably not 72" or longer? Will I be able to tell them what size table I'm planning in building and have them gather the appropriate amount of wood?

|

|

|

|

|

Google Butt posted:I know hard wood comes in irregular sizes, probably not 72" or longer? Will I be able to tell them what size table I'm planning in building and have them gather the appropriate amount of wood? 72" is not a limiting length. You ought to look for a local lumber mill and get enough long boards (12'-14',etc) to do your project, then take that to a cabinet shop and pay them to rip and surface 2 sides- the glue sides (You say you've got a big sander at work for the other 2 sides.) If you're ending up with 1.5" thickness, you'll either want 8/4 lumber that sizes down to that to edge-glue, or you'll laminate up 4/4 lumber like butcher block- you really don't specify. Or you might find a local lumber yard with 1/5" hardwood stile material pre-ripped, s4s, and go with laminating a buttload of that. It would cost the most, I think.

|

|

|

|

I'm sorry, this will definitely be butcher block style. I was thinking 1.5" strips. Edit: I actually found a good deal on a piece of 3/4" carbonized bamboo ply (cut in a cnc too!) $85 out the door. Planning on doing a few coats of tung oil and calling it good, unless there's a better treatment than that. Google Butt fucked around with this message at 02:09 on Sep 29, 2015 |

|

|

|

|

Okay so, I ordered the adjustable sit/stand kee klamp kit, which has no cross bracing. I realize that using a single piece of 3/4" bamboo ply will require some bracing. Would it be less likely to sag/flex with a single cross member running down the middle length wise, or a tube "apron" all the way around the underside of the top?

Google Butt fucked around with this message at 05:30 on Sep 29, 2015 |

|

|

|

|

|

| # ? Apr 28, 2024 21:27 |

|

I finally ordered a G3 to replace my Nova Midi. Saw one on Amazon with 2 sets of jaws, 2" & 1", for $132.30 shipped so I had to own it. Yes I will finally be joining the ranks of modern woodturners not using tommy bar chucks. Also noticed that Nova has faceplates that screw to your chuck, I can't see the purpose of that. Don't think I mentioned it but I sold my '58 Craftsman lathe so I'm down to two lathes although the GP is basically decorative. The Delta is up and running but I'm still working on the wired remote. I was told that switching the potentiometer would stop and start the lathe but that doesn't work on the particular controller I'm using so I'm still figuring that part out. The speed control works fine though. Next I will take it apart and pretty up the wires, make it all look nice.

|

|

|